Elastic waterproof binder additive and preparation method thereof

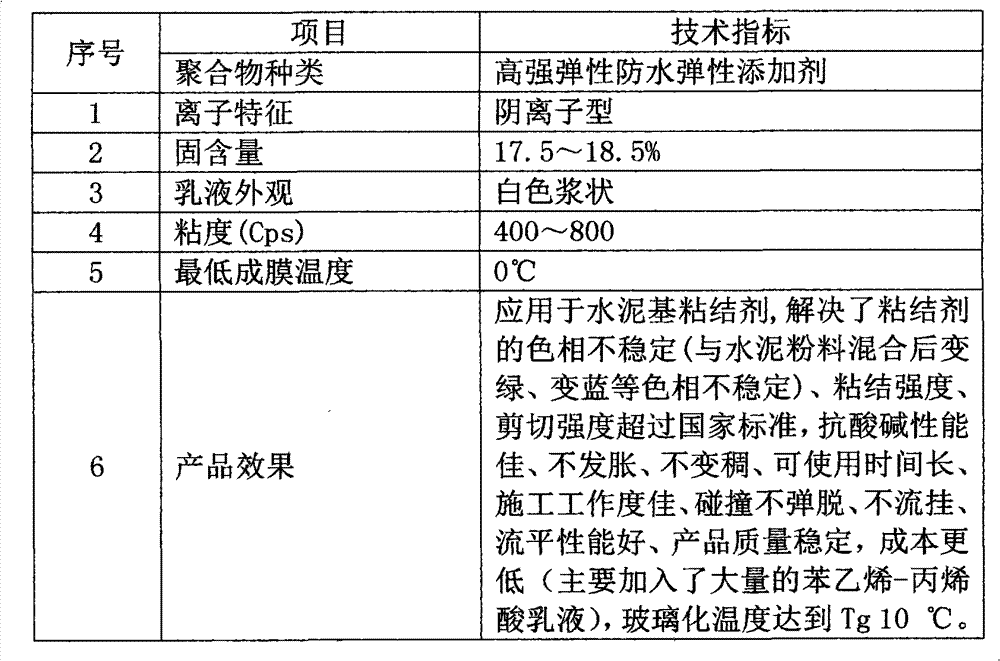

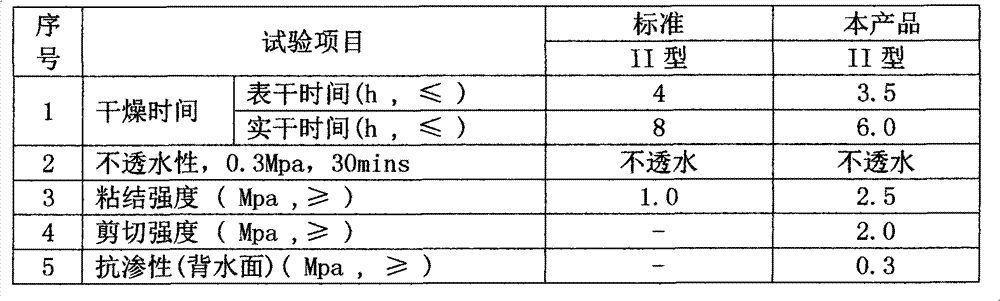

An additive and elastic technology, which is applied in the direction of adhesives, adhesive types, hydrocarbon copolymer adhesives, etc., can solve the problems of bond strength less than 1.5Mpa, shear strength not meeting at the same time, and difficult construction operations. Achieve stable product quality, good acid and alkali resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

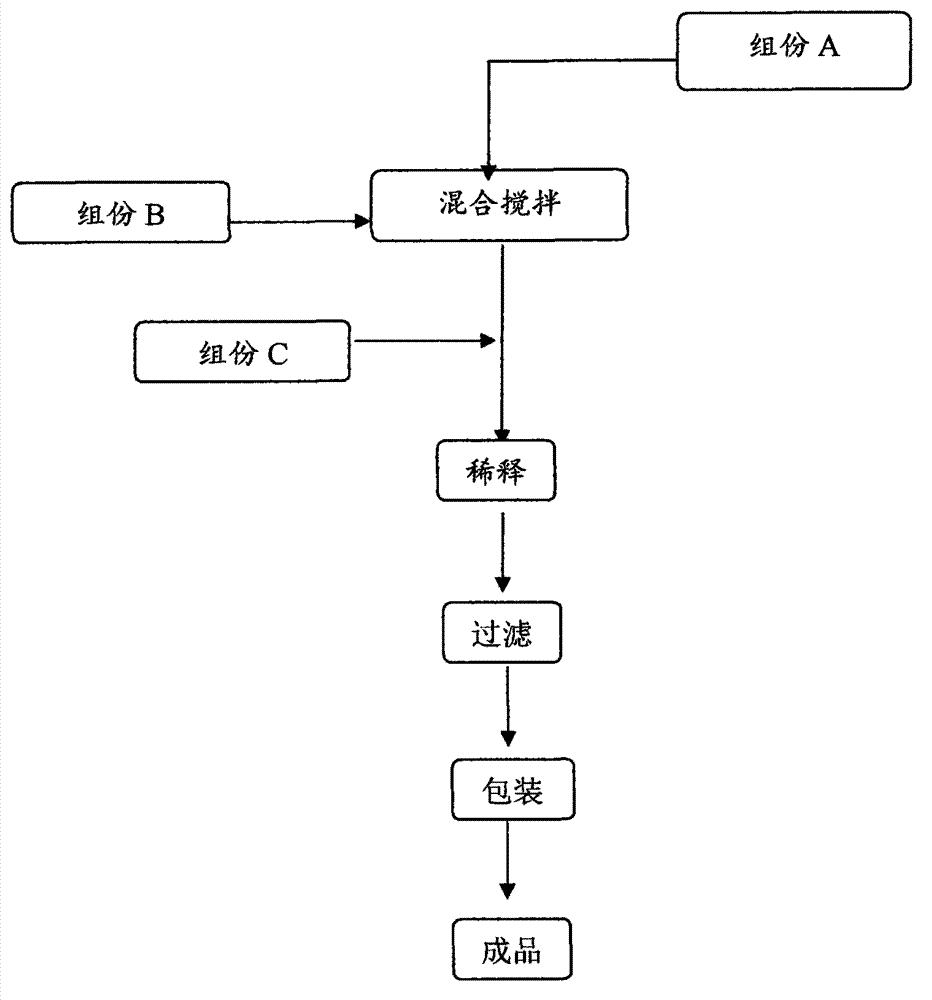

[0029] The elastic waterproof adhesive additive of the present invention and its preparation method will be further described in detail below in conjunction with the accompanying drawings.

[0030] The present invention is an elastic waterproof adhesive additive with improved properties and a preparation method thereof, which is composed of a mixture of three materials, and its composition and weight percentage are as follows:

[0031] (A) component consists of:

[0032] (a) 17.5-19.0% deionized water;

[0033] (b) 0.10~0.20% cellulose ether;

[0034] (c) 0.10% preservatives.

[0035] (B) The composition of component is:

[0036] (g) AOTEN 8100 elastic styrene-acrylate emulsion of 18.0%~20.0%d;

[0037] (h) 8.0% to 10.0% AOTEN 8300 styrene-acrylate emulsion;

[0038] (c) 55.0-56.0% deionized water;

[0039] (C) component, consumption 0.15~0.25%, the composition of this component C is:

[0040] (a) 0.05% to 0.1% organic ammonia neutralizer;

[0041] (b) 0.10% to 0.15% s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com