Yarn

A polytetrafluoroethylene and film technology, applied in the online field, can solve the problems of long production time, long time, core material exposure, etc., and achieve the effects of simple covering structure, good stability and reliability, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 〕

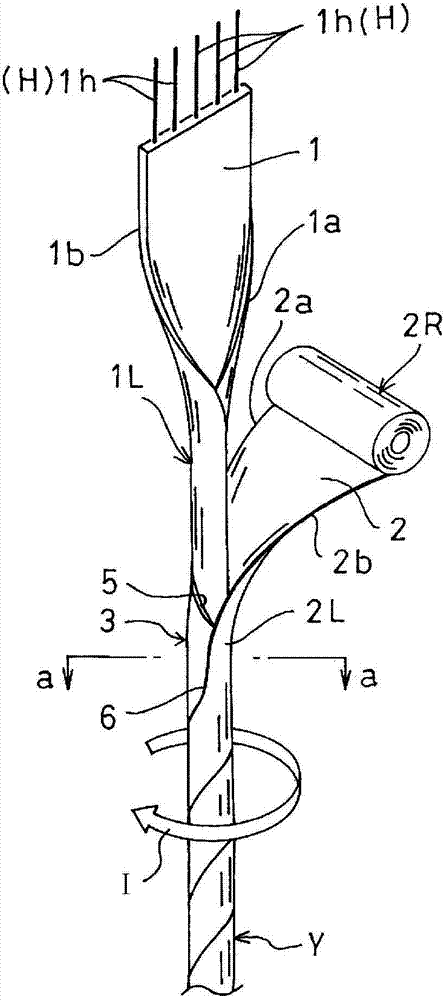

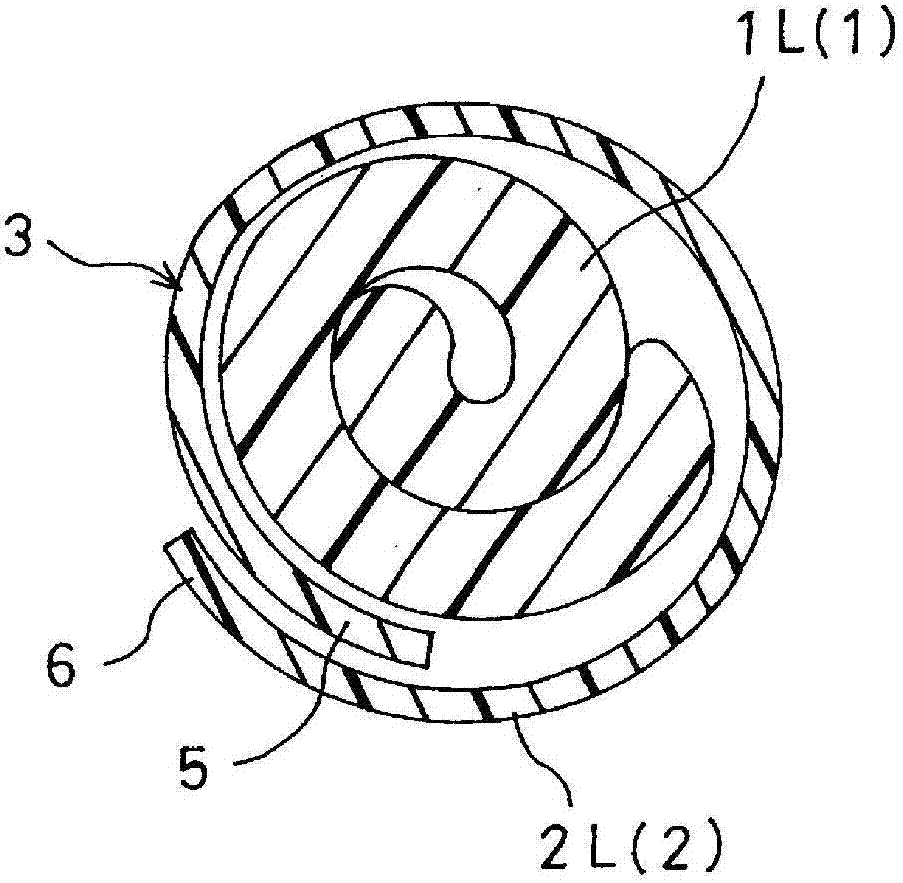

[0043] Such as figure 1 , figure 2 As shown, the line Y of the first embodiment is formed by twisting the base material 3, wherein the base material 3 utilizes the PTFE film under the condition that the PTFE film 2 and the expanded graphite sheet 1 are aligned with each other in the length direction 2 formed by surrounding the expanded graphite sheet 1. That is, as will be described later, it becomes a thread (braided thread) formed by enclosing the rounded inner reinforcing expanded graphite sheet 1 with an outer diameter of 2 mm in the PTFE film 2 .

[0044] The expanded graphite flake 1 as the core material is formed by using elongated expanded graphite (internal reinforced expanded graphite), wherein the elongated expanded graphite is equipped with a plurality of reinforcing wires 1h in a parallel state (inner reinforced expanded graphite). An example), and the cross-sectional shape is a flattened rectangle. The expanded graphite sheet 1 is bent and wound so that one e...

no. 2 example

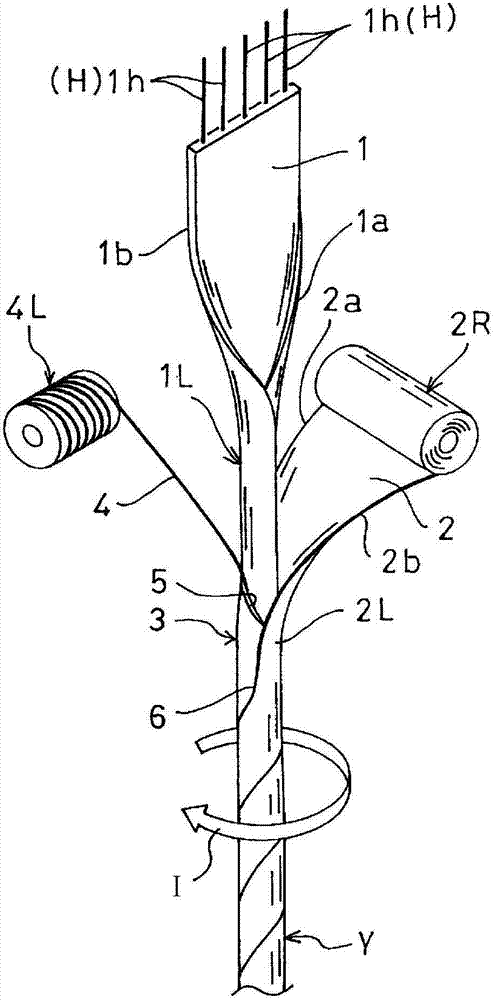

[0049] Such as image 3 As shown, the wire Y of the second embodiment is wrapped in the roll-shaped sheet 1L formed by the expanded graphite sheet 1 through the PTFE film 2, and is wrapped together in the roll 4L unrolled from the stainless steel wire (for example: thick 0.1mm) Stainless steel wire 4 (an example of reinforcement H) as an external reinforcement. That is to say, the wire Y of the first embodiment is also externally reinforced, and the internal and external reinforcement of the reinforced wire 1h(H) as the internal reinforcement and the stainless steel wire 4(H) as the external reinforcement can realize better mechanical properties. Line Y.

[0050] 〔Gland packing〕

[0051] For reference, although the illustration of the gland packing is omitted, the gland packing gathers a plurality (for example, eight) of the wires Y described above (first and second embodiments) around the core material (also There may be no core material) and then twisting or braiding (8-j...

no. 3 example

[0055] Such as Figure 4 , Figure 5 As shown, the line Y of the third embodiment is formed by enclosing the expanded graphite sheet 1 with the rolled PTFE film 2 in a state where the PTFE film 2 and the expanded graphite sheet 1 are aligned in the longitudinal direction. That is, as will be described later, it is a thread (braided thread) formed by wrapping a rounded inner reinforcing expanded graphite sheet 1 with an outer diameter of 2 mm with a PTFE film 2 .

[0056] The expanded graphite sheet 1 as the core material is formed by using a strip-shaped expanded graphite (internal reinforced expanded graphite), wherein the long strip-shaped expanded graphite (internal reinforced expanded graphite) is equipped with a plurality of parallel reinforcements. Line 1h (an example of reinforcement H), and the cross-sectional shape is a flattened rectangle. The expanded graphite sheet 1 is simply bent in the longitudinal direction, and rolled inward so that one end 1 a of the expand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com