Washing machine with preposed water inlet drum

A drum washing machine and water inlet technology, which can be applied to other washing machines, washing devices, textiles and paper making, etc., can solve problems such as environmental pollution of solid detergents, and achieve the effects of improving dissolution effect, increasing utilization rate and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

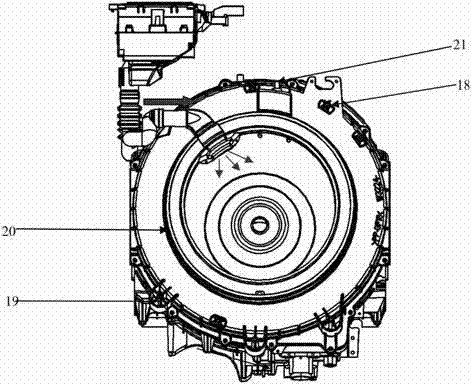

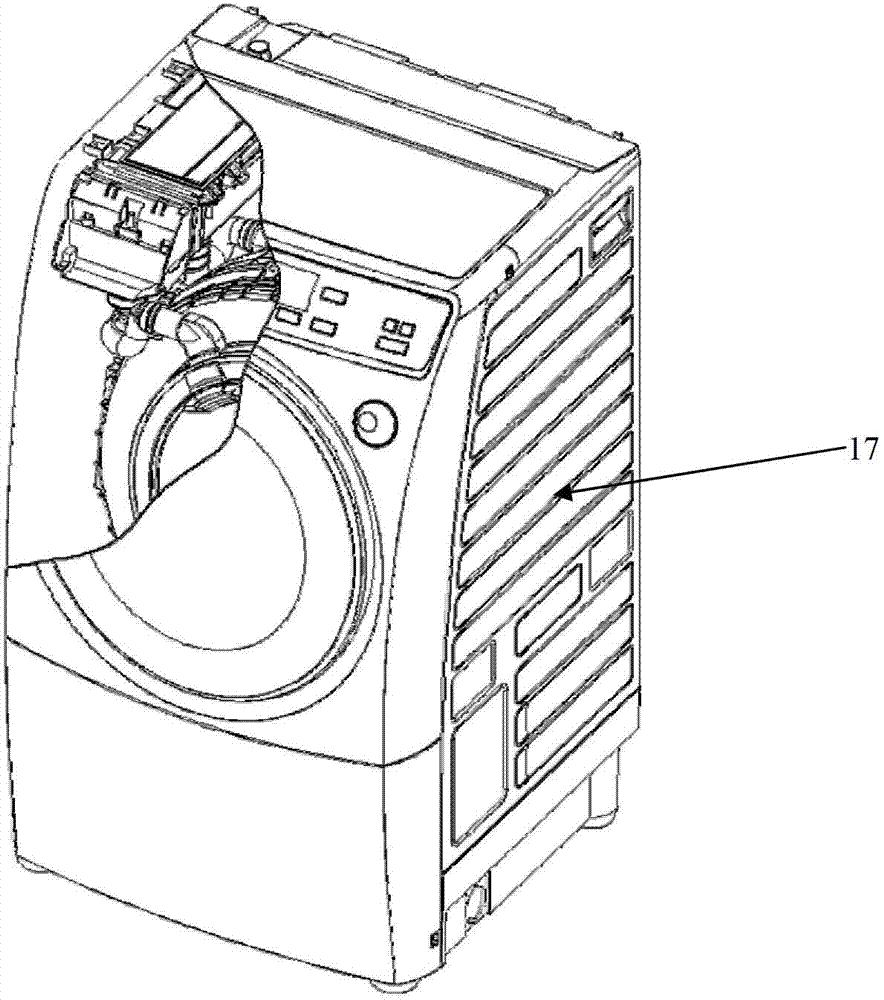

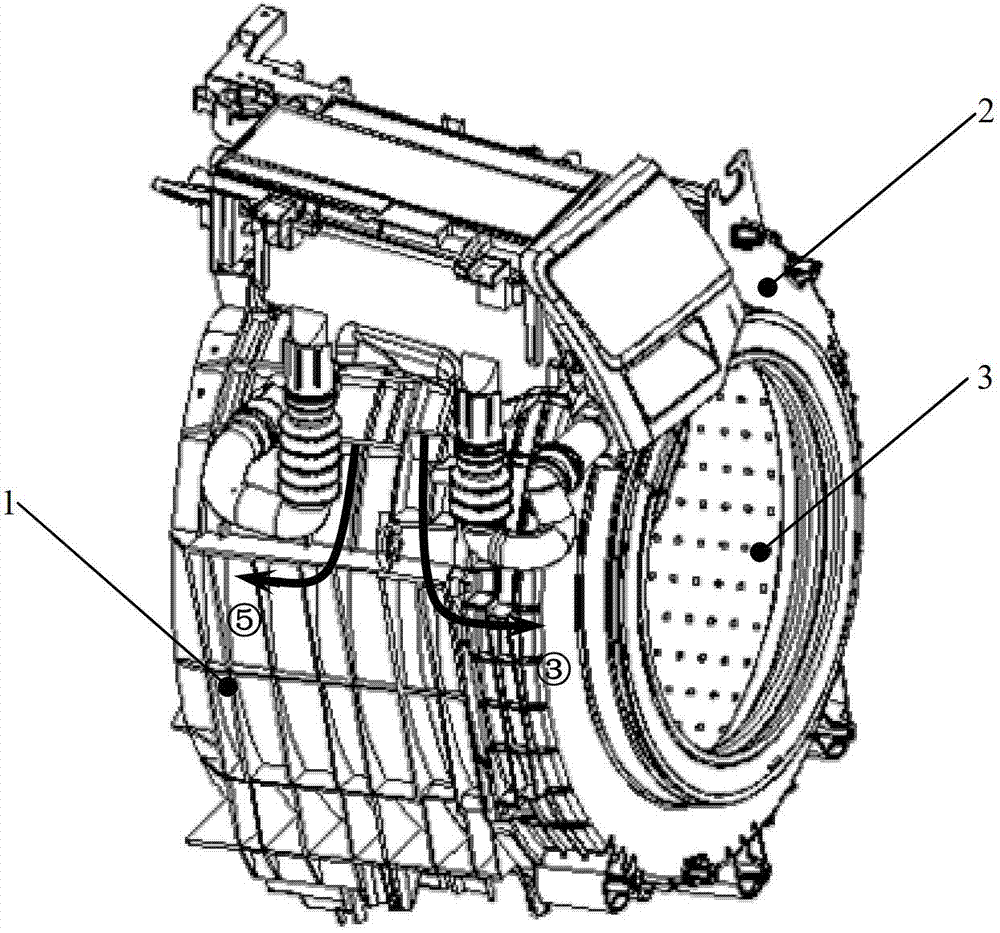

[0025] Refer to figure 1 , 2 5. A front-inlet inclined drum washing machine, the washing tub 3 is inclined upwardly at an angle of 10°-30°, and has a front-inlet channel. The entire front water inlet channel consists of a detergent pre-dissolving device, a water tank frame assembly with a channel structure, a water inlet connecting pipe 9 connecting the pre-dissolving device and the water tank frame assembly, and a dehydration tank rear cover plate installed on the frame 15 and a combination of components such as a water outlet nozzle 16 installed on the rear cover 15 of the dehydration drum to introduce the solution into the washing drum 3. Under no abnormal conditions, the feed water flows into the water tank 1 from the front water inlet channel.

[0026] Refer to Image 6 , 7 , The water tank frame assembly includes a frame body 2 and a dehydration tank rear cover 15. The frame body 2 is provided with an upper balance weight fixing structure 18, a lower balance weight fixing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com