Composite plastic floor

A plastic floor and plastic technology, applied in the field of flooring, can solve the problems of limited production capacity, easy to fall, and the finished product is prone to warping, so as to reduce material and production costs, simplify the production process, and enhance the effect of three-dimensional beauty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

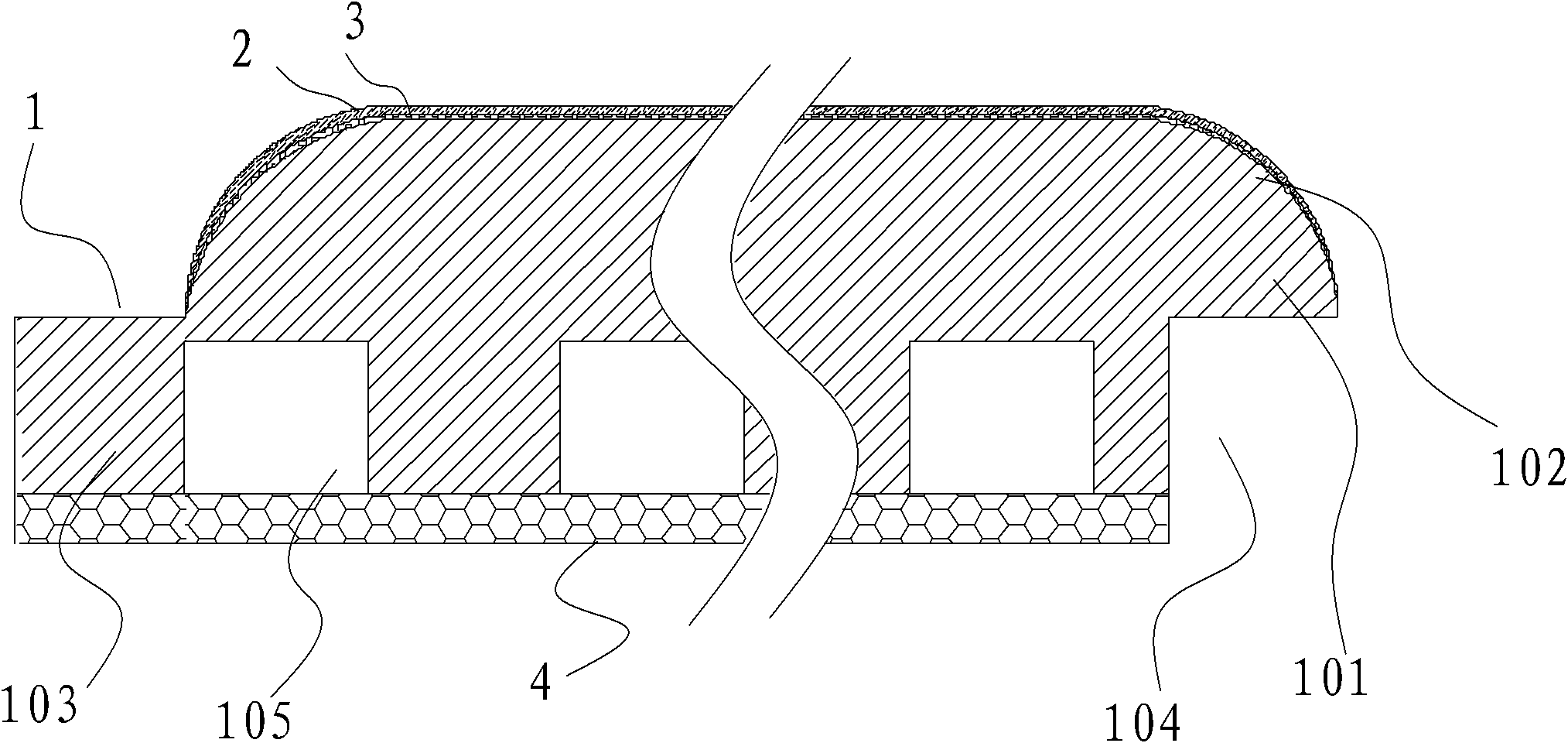

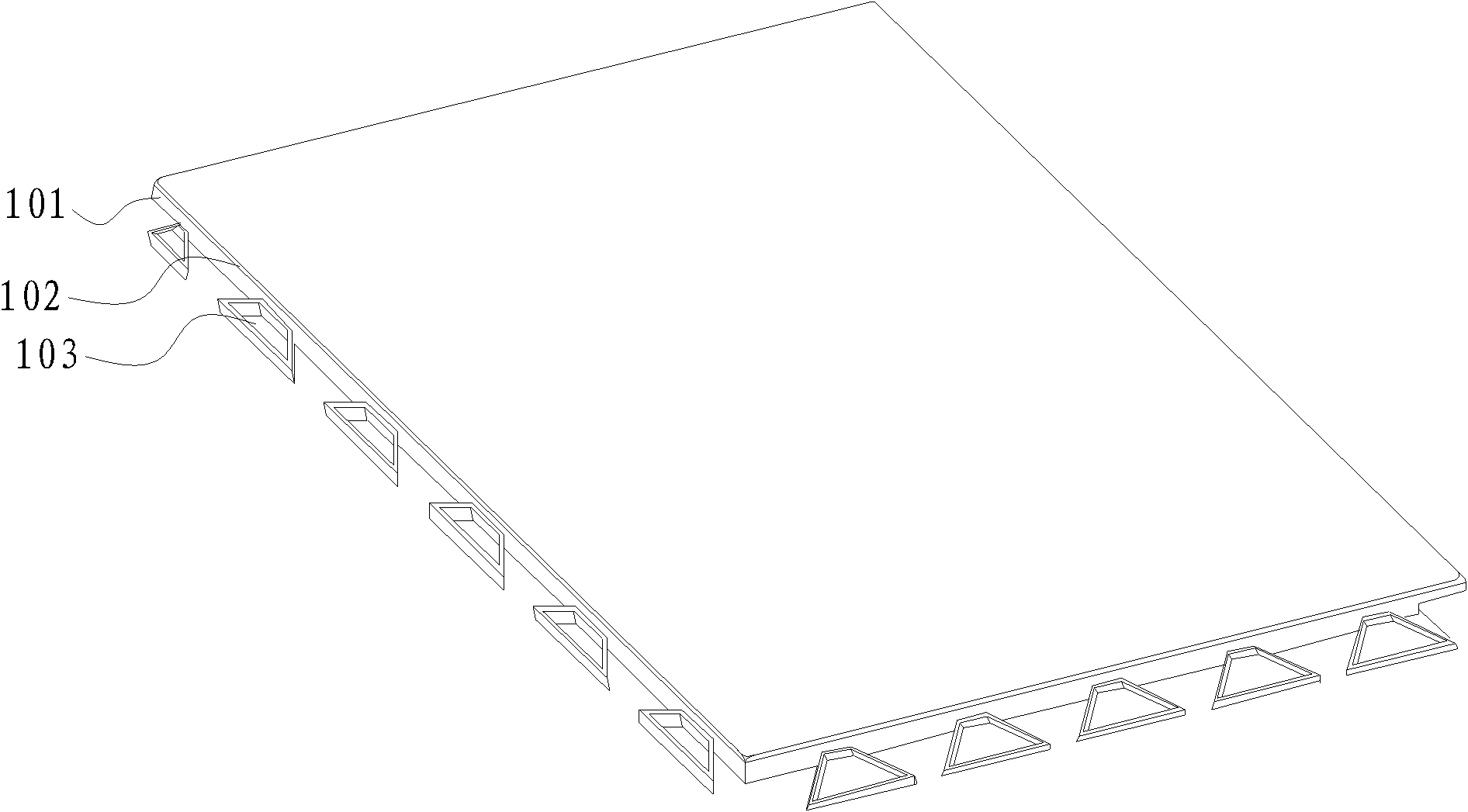

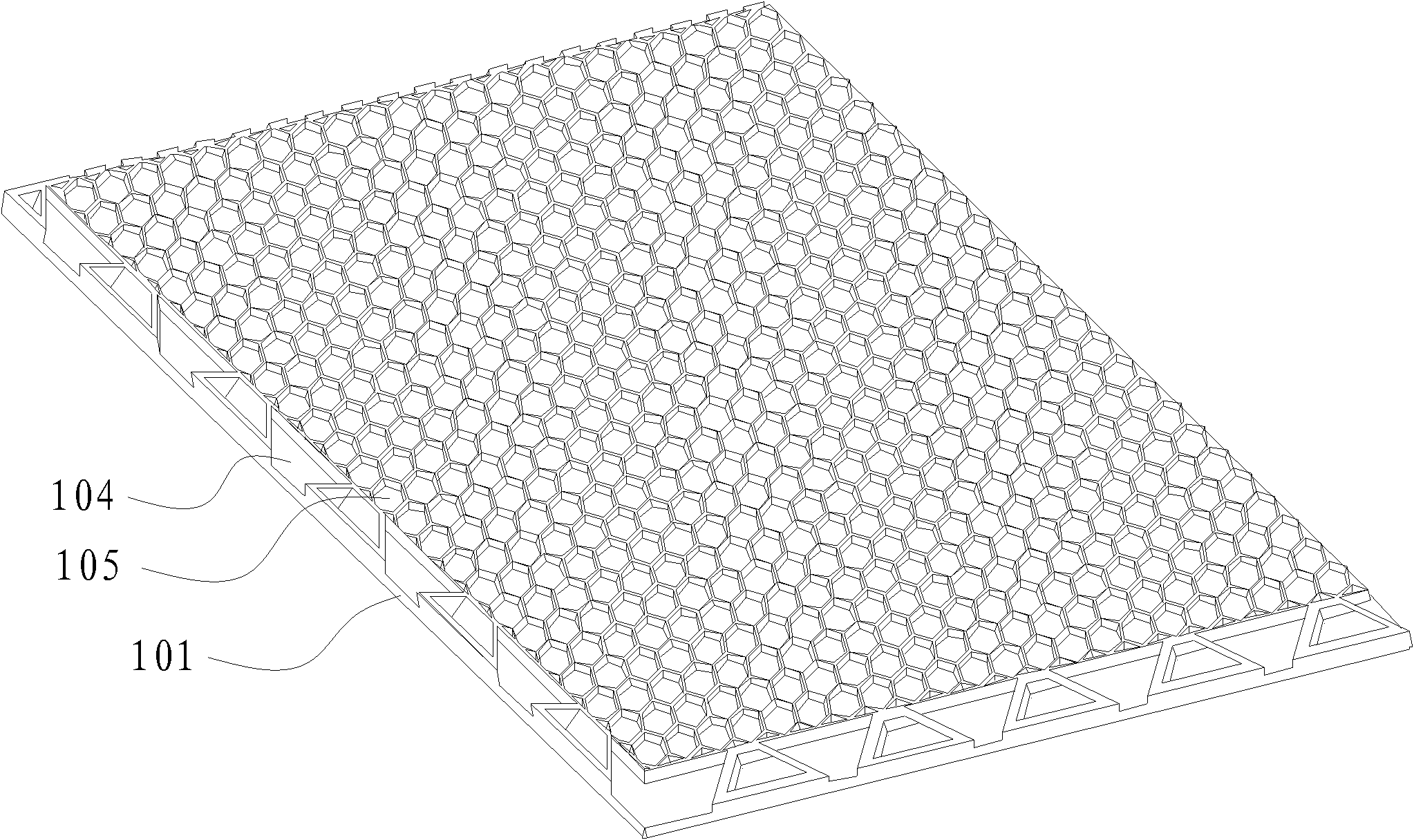

[0038] Such as figure 1 , figure 2 , image 3 , a composite plastic floor, comprising a rectangular plastic base 1 whose upper edge is a circular arc edge 102, the bottom of the plastic base 1 is set as an opaque regular hexagonal hollow structure 105 in the vertical direction, and the depth of the hollow structure 105 is 100 mm. 2 / 3 or more of the thickness of the base 1, the bottom surface of the plastic base 1 is bonded with a non-woven material layer 4, the upper surface of the plastic base 1 is compounded with a PVC transparent wear-resistant layer 2 and a pattern printing layer 3, the plastic base The opposite side of 1 is respectively set as a surface structure side layer and a base structure side layer, and the surface structure side layer is successively a surface layer 101 and a plurality of slot layers horizontally spaced from a plurality of slots 104 from top to bottom, and the base structure side layer There are a corresponding number of card protrusions 103 th...

Embodiment 2

[0040] Such as figure 1 , figure 2 , Figure 4 , a composite plastic floor, comprising a rectangular plastic base 1 whose upper edge is a circular arc edge 102, the bottom of the plastic base 1 is set as an opaque regular hexagonal hollow structure 105 in the vertical direction, and the depth of the hollow structure 105 is 100 mm. 2 / 3 or more of the thickness of the base 1; the bottom of the plastic base 1 is provided with a recessed wire groove 106 whose depth is 1 / 2 of the thickness of the plastic base 1, and the wire groove 106 is covered with a wire groove cover provided with a semicircular groove 107; the bottom surface of the plastic base 1 is bonded with a layer of foamed elastic material 4, the upper surface of the plastic base 1 is compounded with a PVC transparent wear-resistant layer 2 and a pattern printing layer 3, and the opposite sides of the plastic base 1 are respectively set as a surface A structure side layer and a base structure side layer, the surface s...

Embodiment 3

[0042] Such as figure 2 , image 3 , Figure 5 , a composite plastic floor, comprising a rectangular plastic base 1 whose upper edge is a circular arc edge 102, the bottom of the plastic base 1 is set as an opaque regular hexagonal hollow structure 105 in the vertical direction, and the depth of the hollow structure 105 is 100 mm. 2 / 3 or more of the thickness of the base 1, the bottom surface of the four-sided plastic base 1 of the hollow structure 105 is a depression in the middle, and a layer of foaming elastic material 4 is embedded and bonded in the depression in the middle, and the upper surface of the plastic base 1 is compounded with PVC transparent wear-resistant layer 2 and pattern printing layer 3, the opposite sides of the plastic base 1 are respectively set as a surface structure side layer and a base structure side layer, and the surface structure side layer is the surface layer 101 and the horizontal layer from top to bottom. The card slot layer of a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com