On-line real-time purging device of SCR denitration catalyst

The technology of denitration catalyst and multi-layer catalyst is applied in the field of SCR denitration catalyst online real-time purging device, which can solve the problems of low soot blowing intensity of sonic sootblower, large space occupied by telescopic pipe, easy dust accumulation, etc., so as to facilitate construction. Installation and operation and maintenance, stable soot blowing effect, not easy to damage and failure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in conjunction with accompanying drawing and specific embodiment:

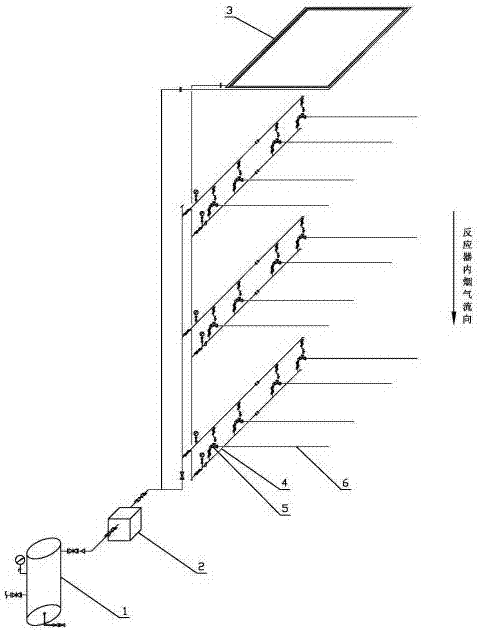

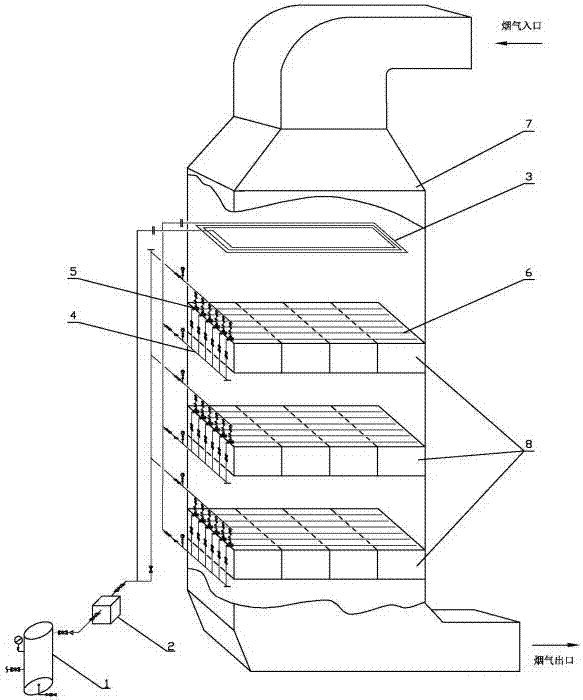

[0012] Such as figure 1 , figure 2 Shown, a kind of SCR denitrification catalyst online real-time purging device, described purging device has the header box 4 that is arranged correspondingly with the multi-layer catalyst bed 8 in SCR denitrification reactor 7; The catalyst bed described in this embodiment 8 is three layers; the headers are three one-to-one corresponding to the multi-layer catalyst bed, and the three headers 4 are located outside the SCR denitration reactor 7; the headers 4 are the length The seamless steel pipe with the same width as the catalyst bed on the installation side is designed according to the working condition of the maximum gas consumption of each layer. The front end is connected to the preheating device in the reactor through a pipe, and the rear end is blocked by a steel plate or a standard head; The headers 4 of each stage are insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com