Automatic measuring device for circumference of spiral submerged-arc welding pipe

A submerged arc welded pipe, automatic measurement technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as inability to achieve real-time measurement, poor working environment, and inability to meet production requirements, and achieve good promotion and use prospects , On-site adaptability, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

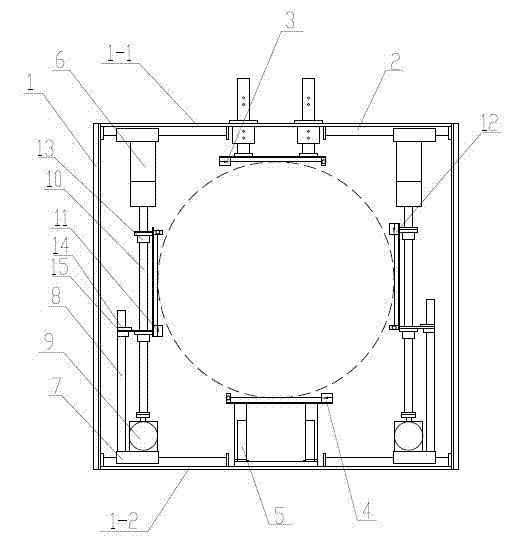

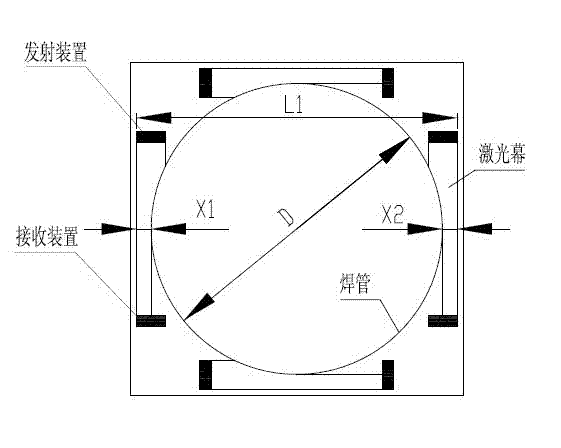

[0016] Such as figure 1 As shown, an automatic measurement device for the perimeter of a spiral submerged arc welded pipe, the left and right sides of the upper fixed beam 1-1 and the lower fixed beam 1-2 of the fixed frame 1 are respectively provided with linear guide rails 2; the upper CCD laser micrometer 3 It is fixed between the two linear guide rails 2 of the upper fixed beam 1-1 by a fixed bracket 5 or a telescopic fixed bracket, and the lower CCD laser micrometer 4 is fixed on the lower fixed beam 1-1 by a fixed bracket 5 or a telescopic fixed bracket. 2 between the two linear guides 2.

[0017] The two ends of the ball screw 10 are slidably matched with the linear guide 2 through the sliding block 7 respectively, and the left and right CCD laser micrometers 11 and 12 are respectively connected with the ball screw 10 through two ball nuts 13, and the sliding block can drive the ball screw left and right. Moving, the CCD laser micrometer includes a transmitting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com