Device for detecting service life of valve core of water nozzle

A detection device and faucet technology, which is used in measuring devices, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problems of not being able to test the life of the faucet handle, affecting the accuracy of test data, etc., and achieving cost-effectiveness High, compact structure, good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

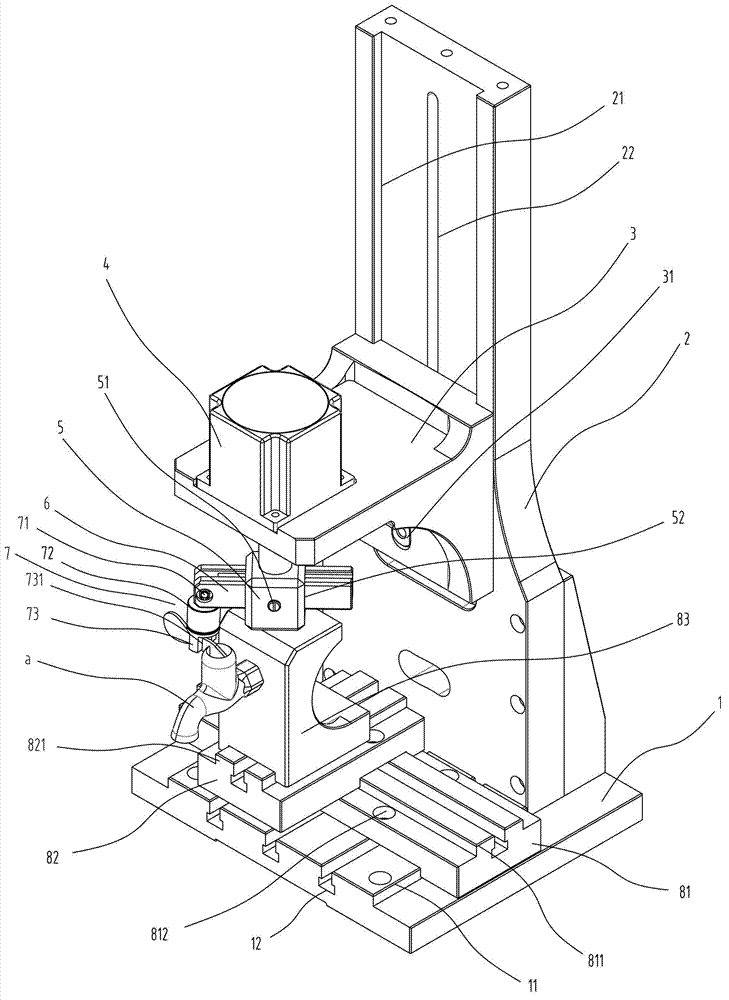

[0026] Embodiment one, with reference to figure 1 As shown, the universal faucet spool life detection device suitable for single-handle single-control faucet a includes a base 1, a column 2 set on the base 1, and a faucet that can be adjusted in the X and Y axis directions on the base 1 The positioning mechanism of the faucet, the sliding seat 3 arranged on the column 1 that can be moved up and down vertically, the motor 4 vertically installed on the sliding seat 3, and the horizontally penetrating guide hole 52 formed at the lower end of the output shaft of the motor 4 The rotary member 5, the swing rod 6 that is movable through the guide hole 52 of the rotary member 5, the locking bolt 51 that can lock or release the swing rod 6 on the rotary member 5, and the one end of the swing rod 6 that can be connected with The clamp 7 that the faucet handle matches.

[0027] A vertically extending Z-axis guide rail 21 is formed on the column 1. The slide seat 3 is movably arranged on...

Embodiment 2

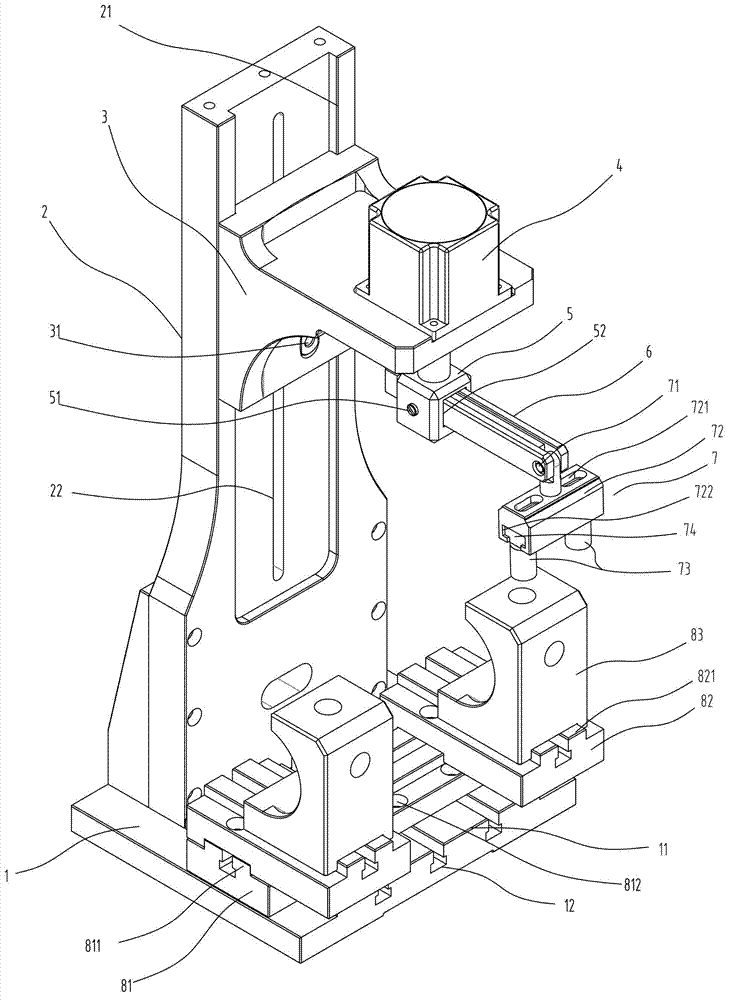

[0031] Embodiment two, refer to figure 2 As shown, the universal faucet spool life detection device suitable for single-handle double-control kitchen faucet is used to simulate the faucet to swing the faucet outlet pipe under manual operation to switch the water supply tank. Its main structure is the same as that of Embodiment 1. The main difference is: the faucet positioning mechanism and the 7 parts of the fixture. In order to adapt to the cold and hot water supply of the single-handle double-control kitchen faucet, two faucet mounting seats 83 for fixing the cold and hot water inlet ends need to be provided. The specific faucet positioning Two upper carriages 82 are movable on the X-axis guide rail 811 of the mechanism, and the second Y-axis guide rail 821 is formed on the two upper carriages 82 respectively, and the two nozzle mounting seats 83 are correspondingly arranged on the two upper carriages 82. on the second Y-axis guide rail 821 .

[0032] The clamp 7 includes ...

Embodiment 3

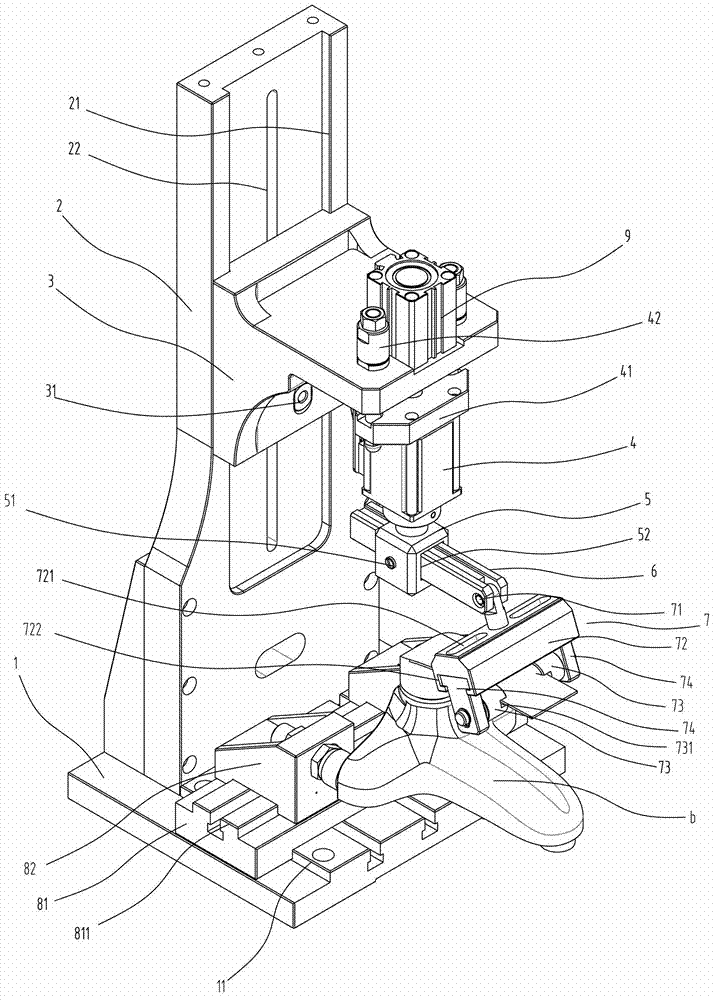

[0034] Embodiment three, refer to image 3 As shown, the universal faucet spool life detection device suitable for single-handle double-control faucet b is used to simulate the adjustment of the cold and hot water ratio and the water outlet switch control of the faucet under manual operation, including base 1, set on base 1 The column 2 on the top, the nozzle positioning mechanism that is set on the base 1 and can adjust the position of the nozzle in the X and Y axis directions, the sliding seat 3 that can be vertically moved up and down and adjusted on the column 1, and the vertical setting on the sliding seat 3 The cylinder 9, the motor mounting seat 41 connected to the lower end of the piston rod of the cylinder 9, the guide column 42 arranged between the motor mounting seat 41 and the sliding seat 3, the motor 4 vertically installed on the motor mounting seat 41, the motor mounting seat 41 arranged on the motor 4 The lower end of the output shaft is formed with a rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com