Method and system for testing abrasiveness of rock

An abrasive and rock-based technology, applied in measuring devices, soil material testing, particle size analysis, etc., can solve problems such as difficulty in fully reflecting heterogeneous stratum rocks, lack of contrast in data, and difficulty in establishing a continuous section of abrasiveness in regional rocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

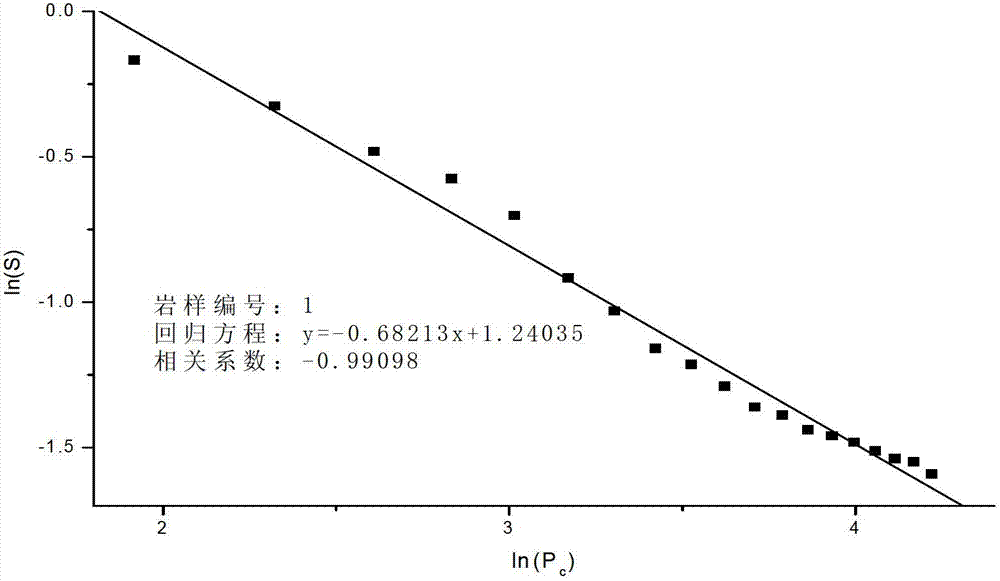

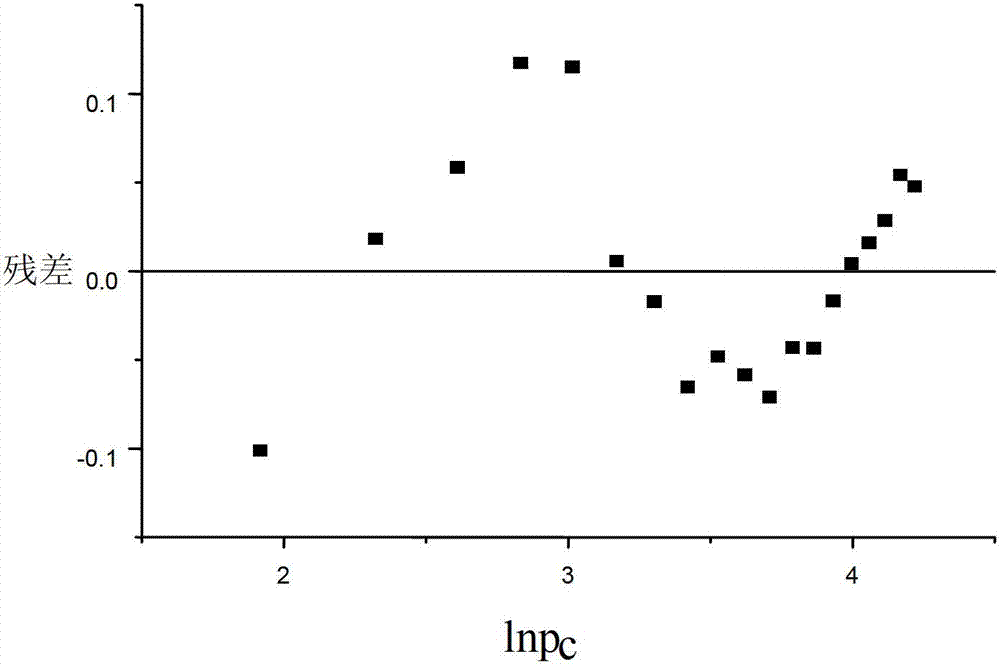

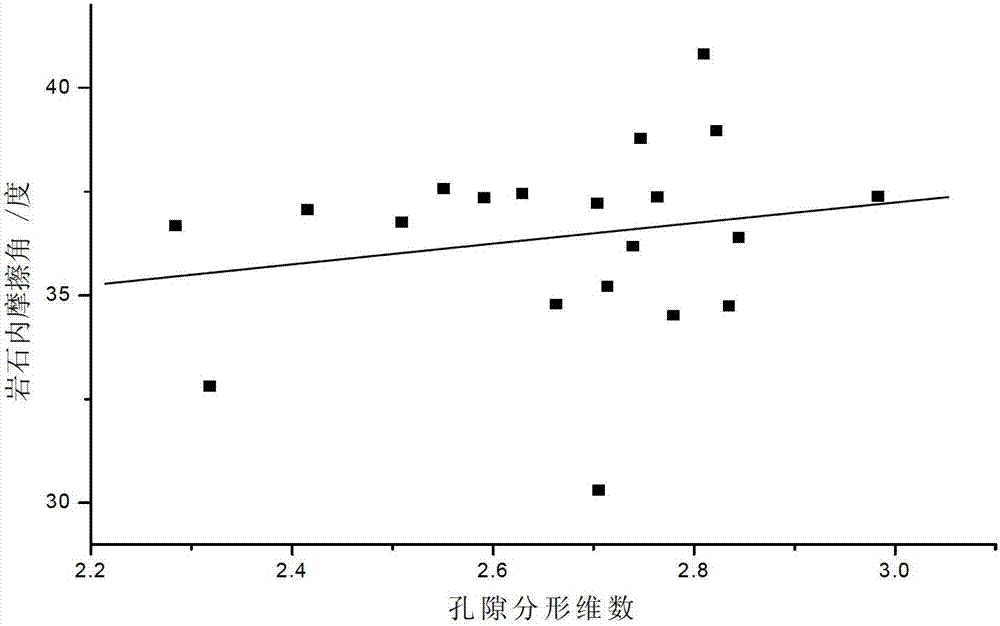

[0086] Based on the above studies by the inventors, a method for measuring the abrasiveness of rocks has been proposed. The method may generally include the following steps: predetermine the relationship between the internal friction angle of the rock and the particle size fractal dimension of the rock; obtain a rock chip sample on site, and measure its particle size fractal dimension; And the above relational formula, determine the internal friction angle of the cuttings sample.

[0087] Refer below Figure 9 This method will be described in detail. In addition, in the following, duplicate descriptions will be omitted for parts that overlap with the above content.

[0088] First, in step S11, the relationship between the internal friction angle of the rock and the particle size fractal dimension of the rock is determined.

[0089] Specifically, a number of different rock samples are collected from a number of different locations, such as various types of rock samples from ...

no. 2 approach

[0115] The present invention can also be implemented as a method for determining the abrasiveness of rocks as follows. The method may include the following steps: obtaining a rock chip sample on site, and measuring its particle size fractal dimension; determining the The internal friction angle of this rock chip sample.

[0116] In this method, the predetermined relationship between the internal friction angle of the rock and the particle size fractal dimension of the rock can be obtained through the processing of the above step S11.

[0117] Other aspects of the method are the same as those of the above-mentioned first embodiment, so details are not repeated here.

[0118] According to the second embodiment, the same advantages as those of the first embodiment can be achieved. In addition, in the second embodiment, the relationship between the predetermined internal friction angle of the rock and the particle size fractal dimension of the rock can be obtained from others, s...

no. 3 approach

[0120] The present invention can also be implemented as a rock abrasiveness measurement system. Detailed description will be given below.

[0121] like Figure 10 As shown, the rock abrasiveness measurement system of this embodiment may include: a storage unit 21 , a particle size fractal dimension measurement unit 22 and a calculation unit 23 . In addition, an input unit 24 and an output unit 25 may be further included.

[0122] The storage unit 21 stores a predetermined relationship between the internal friction angle of the rock and the fractal dimension of the rock particle size. The relationship may be in the form of a formula, or in the form of a mapping table, and is not limited here. The predetermined relationship between the internal friction angle of the rock and the particle size fractal dimension of the rock can be obtained through the processing of step S11 in the above-mentioned first embodiment, and will not be repeated here.

[0123] The storage unit 21 can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of internal friction | aaaaa | aaaaa |

| Angle of internal friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com