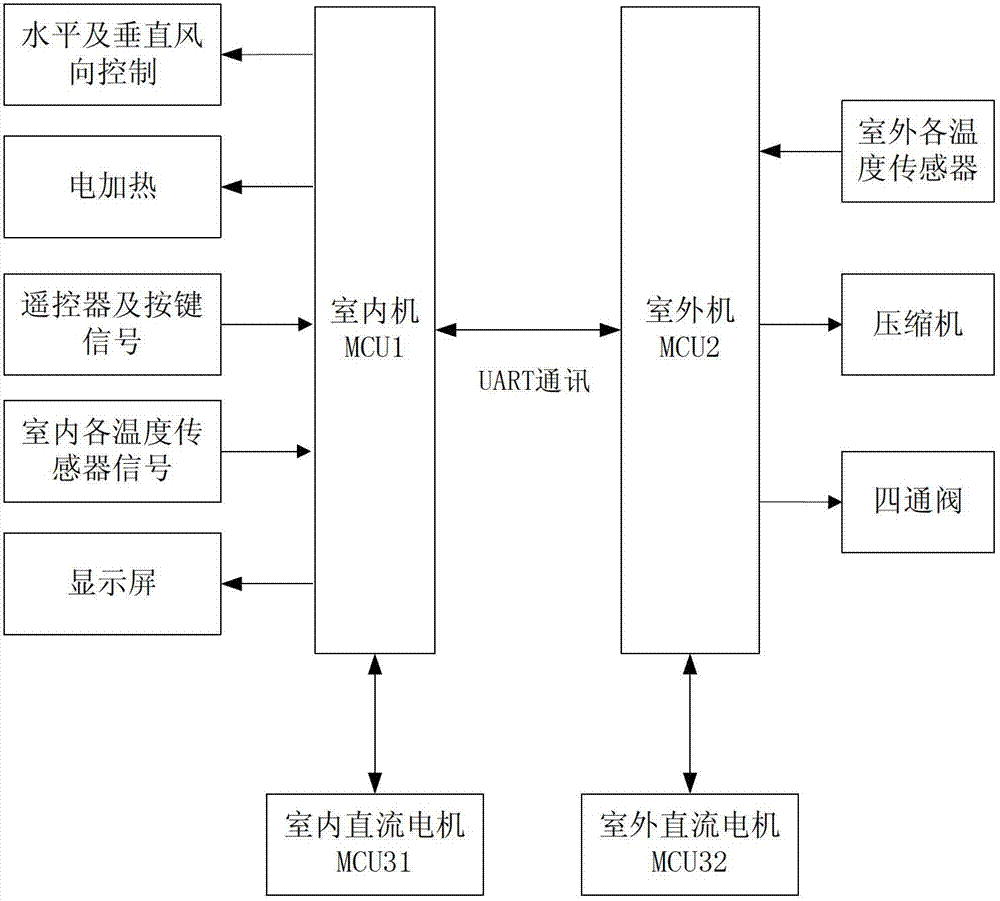

Debugging tooling and debugging method for direct-current air conditioner motors

A technology of DC motors and debugging tooling, applied in the direction of motor generator testing, etc., can solve problems such as large labor costs, software design, and debugging errors, and achieve the effects of speeding up development, improving product quality, and being simple and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

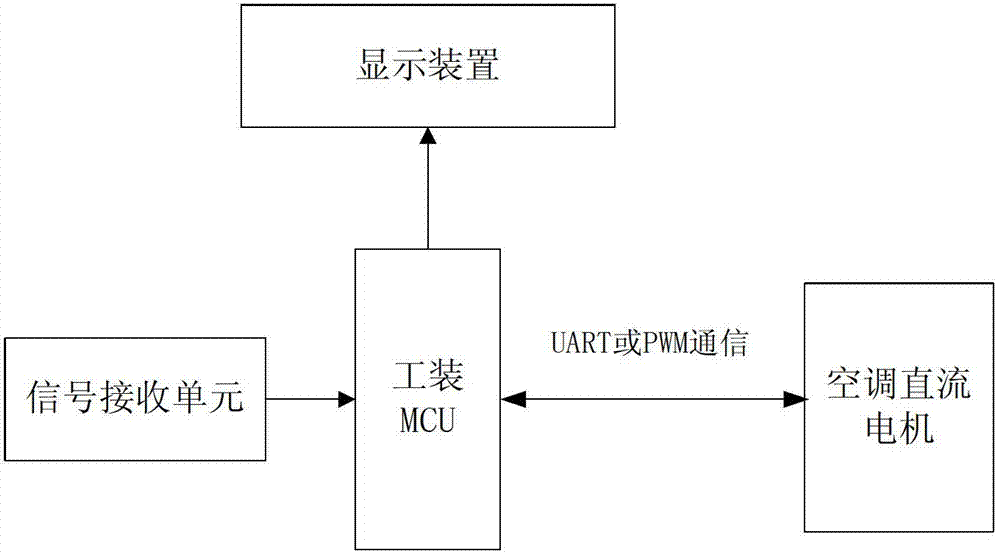

[0024] like figure 2 The debugging tooling and debugging method of the air conditioner DC motor shown in the present invention include a signal receiving unit and a display device connected to the tooling MCU in the debugging tooling, wherein the tooling MCU is used to receive and process signals input by the signal receiving unit, and according to the input signal Control the speed of the DC motor of the air conditioner, and display the corresponding parameters on the display device; the signal receiving unit may include a remote control receiving module and a key receiving module, which are used to receive control signals from the remote control and panel keys respectively. The display screen of the display device is in the form of LED or LCD, and the display screen includes a 4-digit digital tube for displaying the speed range of 0000~9999, so as to meet the display requirements of various motor speeds. The debugging tooling is directly connected to the DC motor of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com