Escapement mechanism, in particular for a clockwork

A technology of escapement and movement, applied in escapement, frequency-stabilizing mechanism, frequency-stabilizing mechanism, etc., can solve problems such as cumbersomeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

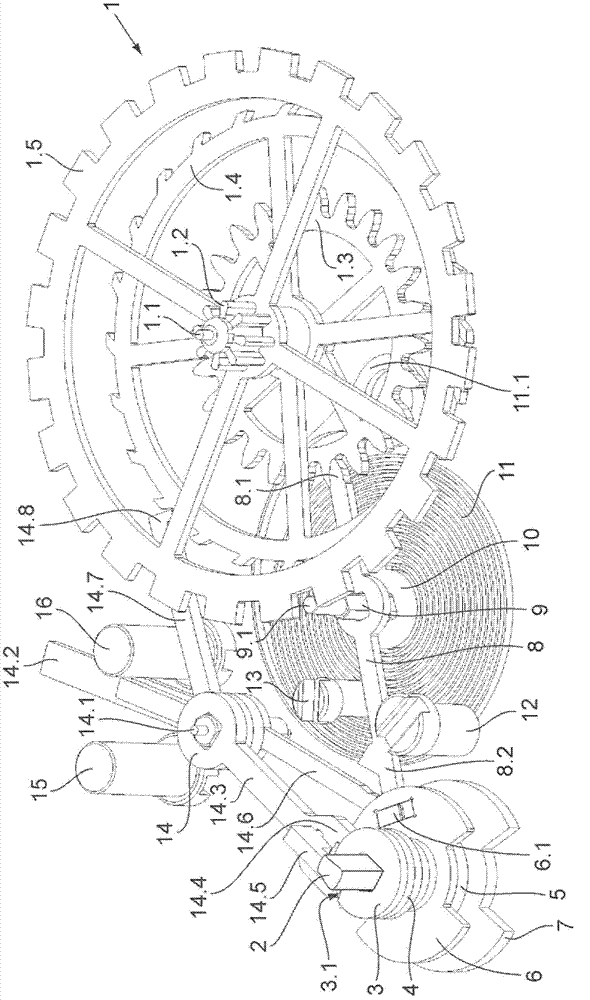

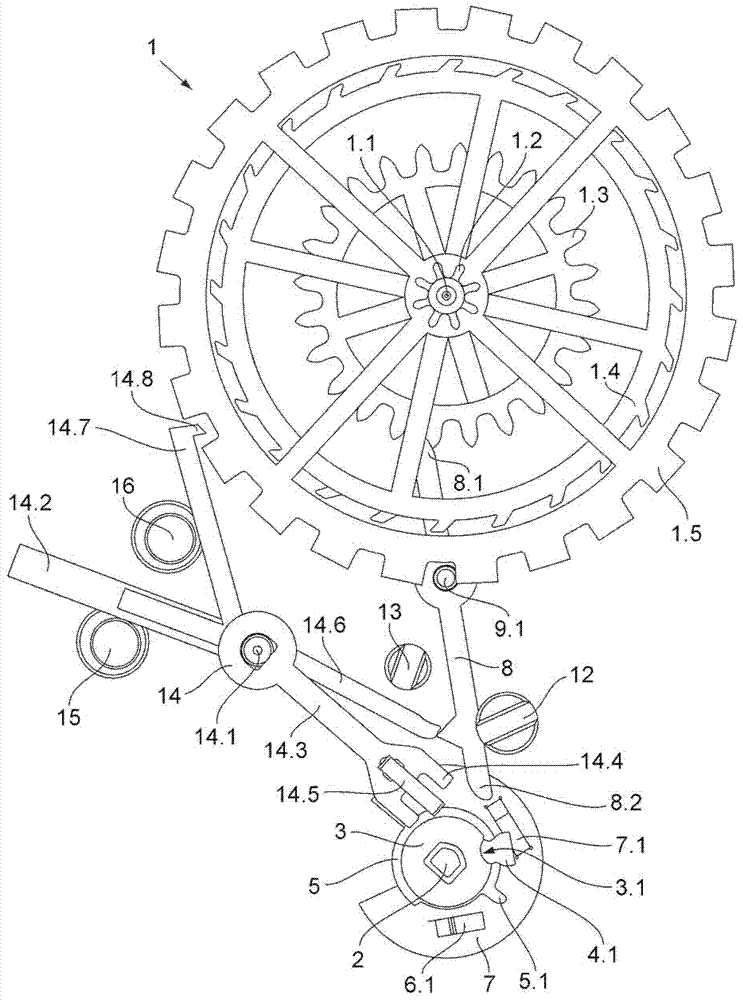

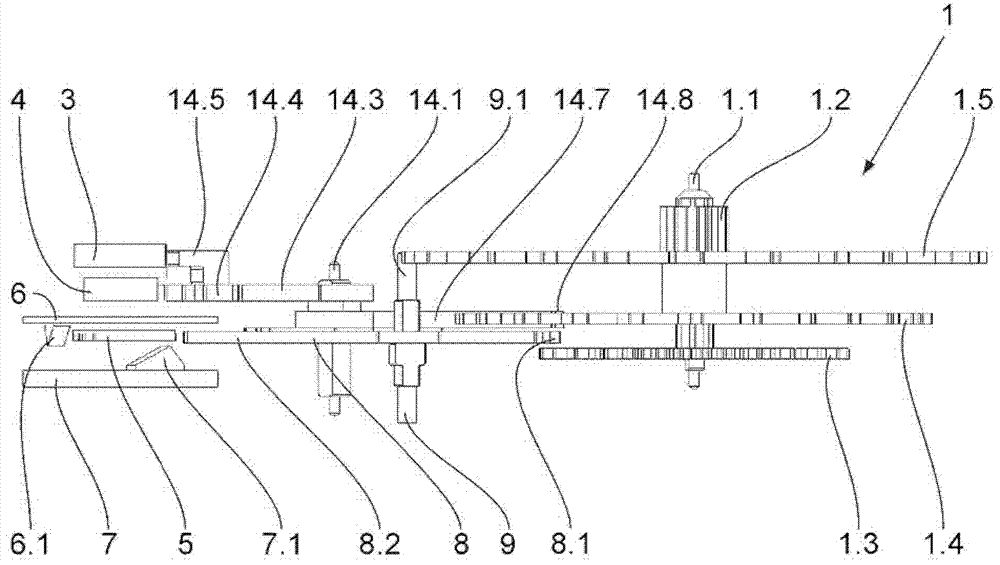

[0018] The accompanying drawings illustrate a constant-force escapement according to the invention, comprising a constant-force auxiliary spring and intended to be equipped in a timepiece movement in which there is a spring balance and by The running wheel train is connected to the escapement transmission of the barrel. Said constant-force escapement is characterized in that it comprises a striking lever pivotally mounted on a part of the frame of the movement, which on the one hand cooperates with the escapement transmission and on the other hand is fixed to the mainspring arbor and in that said constant force auxiliary spring is fixed at one end thereof to a part of the frame of the movement and at the other end to the shaft of the striking rod.

[0019] In the embodiment explained by way of example, the constant-force escapement has an escapement transmission 1 comprising an escapement pinion 1.2 mounted on a shaft 1.1, the escapement pinion passing through a running train ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com