Canny operator-based foam boundary recognition and grain size analysis method

A technology of boundary recognition and particle size analysis, applied in character and pattern recognition, computing, computer parts and other directions, can solve the problems of less detection point information, difficult to accurately extract image contours, etc., achieve good pertinence, reduce processing objects, enrich The effect of data content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

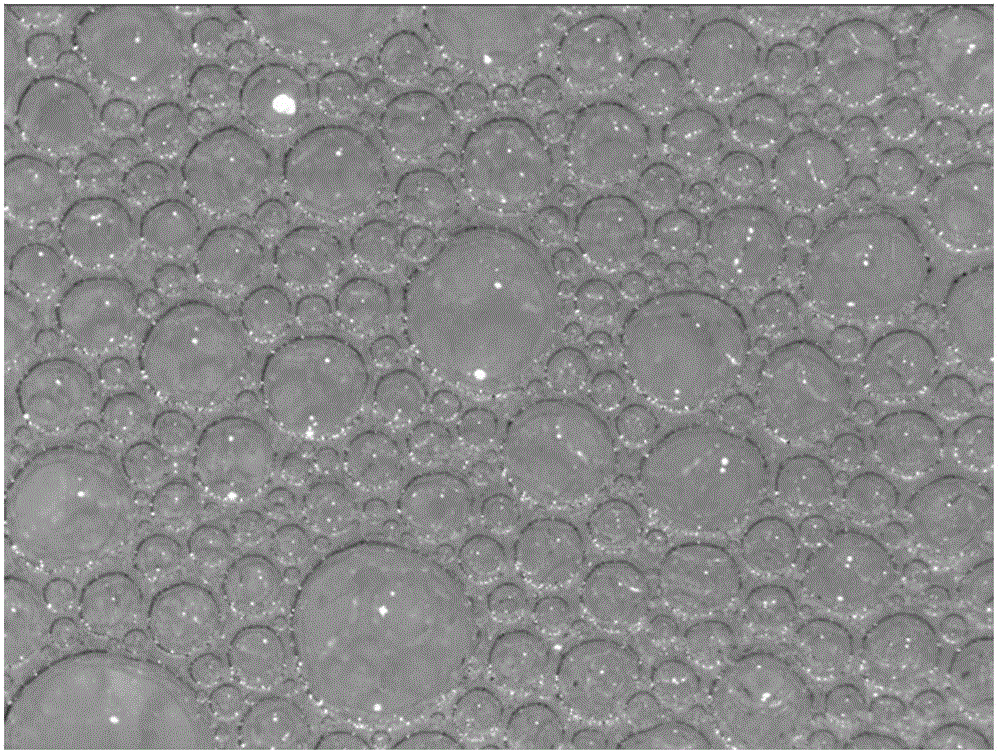

[0067] Step (1) Import the image, collect the foam image through a stereo microscope, adjust the brightness of the side light source and the ring cold light source of the stereo microscope during the acquisition process, supplemented by adjusting the contrast, exposure, and brightness of the software, and obtain a clear boundary bubble image;

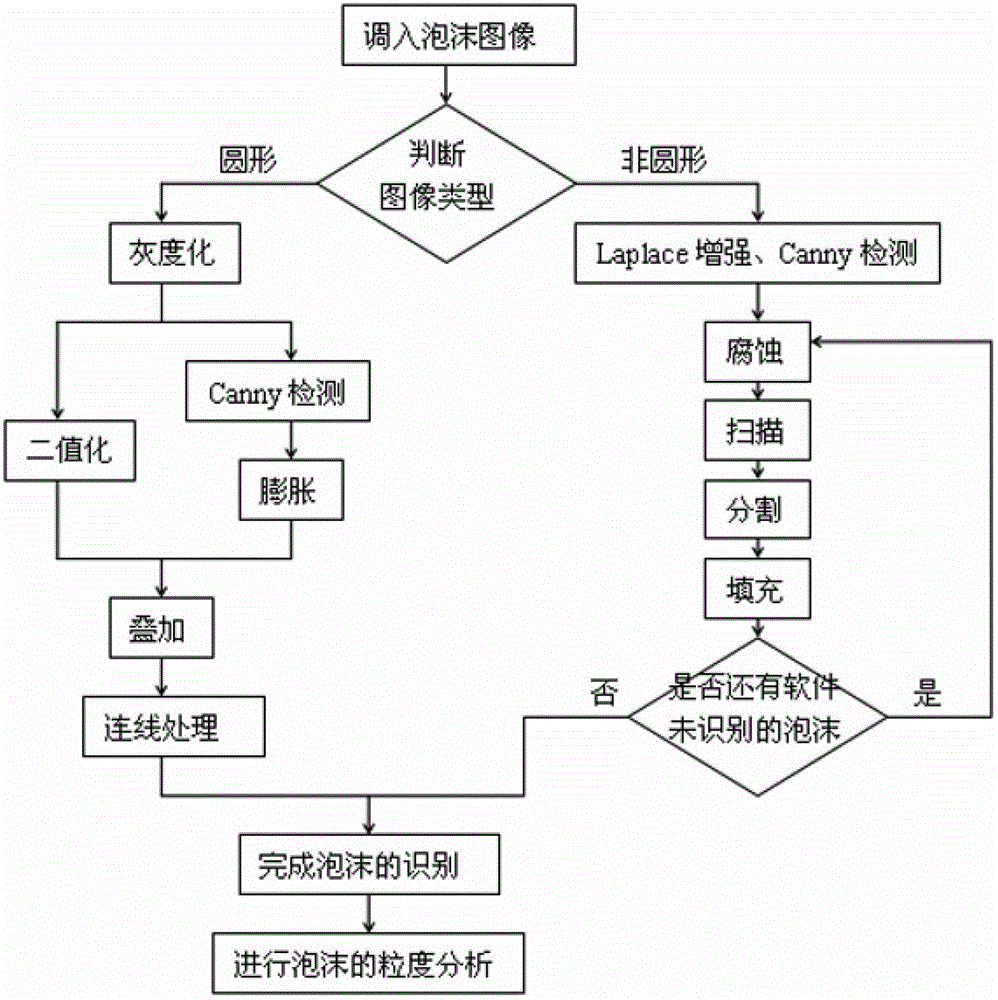

[0068] Step (2) Judging the image, judging the type of foam according to the overall state of the foam in the image, the distance between the left and right borders of the foam and the upper and lower borders of the foam is less than 15% of the average distance between the borders (that is, the diameter of the foam), then the foam is a circle Shaped foam, in the image analyzed in this example, the proportion of circular foam to all foams is greater than 90%, so select "Circular Foam Recognition";

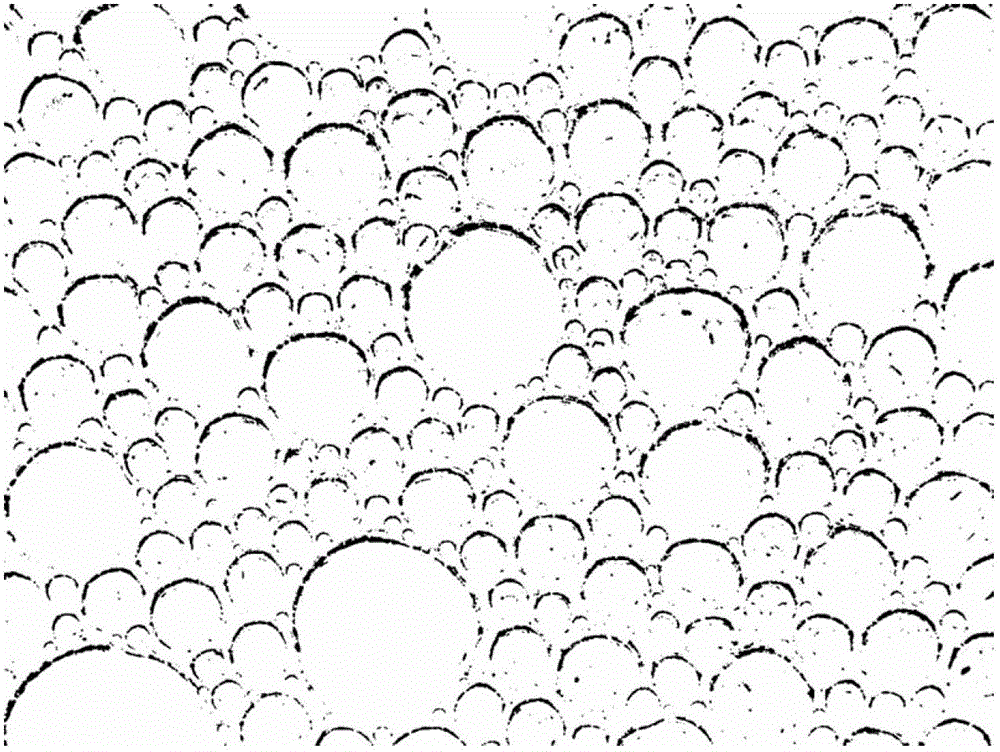

[0069] Step (3) Use "circular bubble recognition", first grayscale the original image, and get figure 2 , and then on the one hand, logari...

Embodiment 2

[0073] Step (1) Import the image, collect the foam image through a stereo microscope, adjust the brightness of the side light source and the ring cold light source of the stereo microscope during the acquisition process, supplemented by adjusting the contrast, exposure, and brightness of the software, and obtain a clear boundary bubble picture;

[0074] Step (2) Judging the image, judging the type of foam according to the overall state of the foam in the image, the distance between the left and right borders of the foam and the upper and lower borders of the foam is less than 15% of the average distance between the borders (that is, the diameter of the foam), then the foam is a circle In the image analyzed in this example, the proportion of circular foam to the total foam is far less than 90%, so select "Non-circular foam recognition";

[0075] Step (3) using "non-circular foam identification", firstly Figure 10 Perform Laplace enhancement to get Figure 11 , get the promin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com