Composite drive type switch reluctance motor with chute structure

A switched reluctance motor, driving technology, applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problems of low work efficiency, easy to produce fatigue, and labor-intensive users, and achieve work efficiency. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

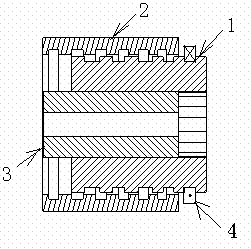

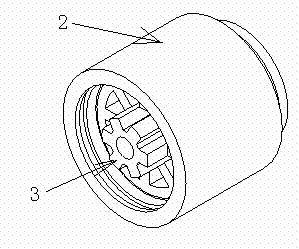

[0010] As shown in the figure, the composite drive switched reluctance motor with a chute structure includes a stator 1, an outer linear drive rotor 2 and an inner rotary drive rotor 3. The stator 1 is made of laminated silicon steel sheets, and there is an excitation magnet on the stator 1. The coil 4 has an external thread on the outer peripheral surface of the stator 1, and an internal thread on the inner wall of the outer linear drive rotor 2 that matches the external thread on the outer peripheral surface of the stator 1. Under the action of electromagnetic force, the outer linear drive rotor 2 is on the stator. 1 rotates axially while rotating, and the internal rotation drives the rotor 3 to be a rotor with a chute structure, and the internal rotation drives the rotor 3 to rotate under the action of tangential electromagnetic force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com