Bulk acoustic wave resonator and method of manufacturing thereof

A resonator, bulk acoustic wave technology, applied in resonators, waveguide devices, impedance networks, etc., to avoid measurement and simplify driving integrated circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0074] Example 1: SE plate oriented along crystallographic direction, circular void

[0075] A single crystal silicon plate resonator operating in SE mode is analyzed. The side edges of the plate are aligned along the crystal direction and have a side length of L=320 μm. The optimal circular void radius is 38 μm ( Figure 6a ). Figure 6b The frequency variation of a similar resonator reduced in size by a factor of two is shown.

example 2

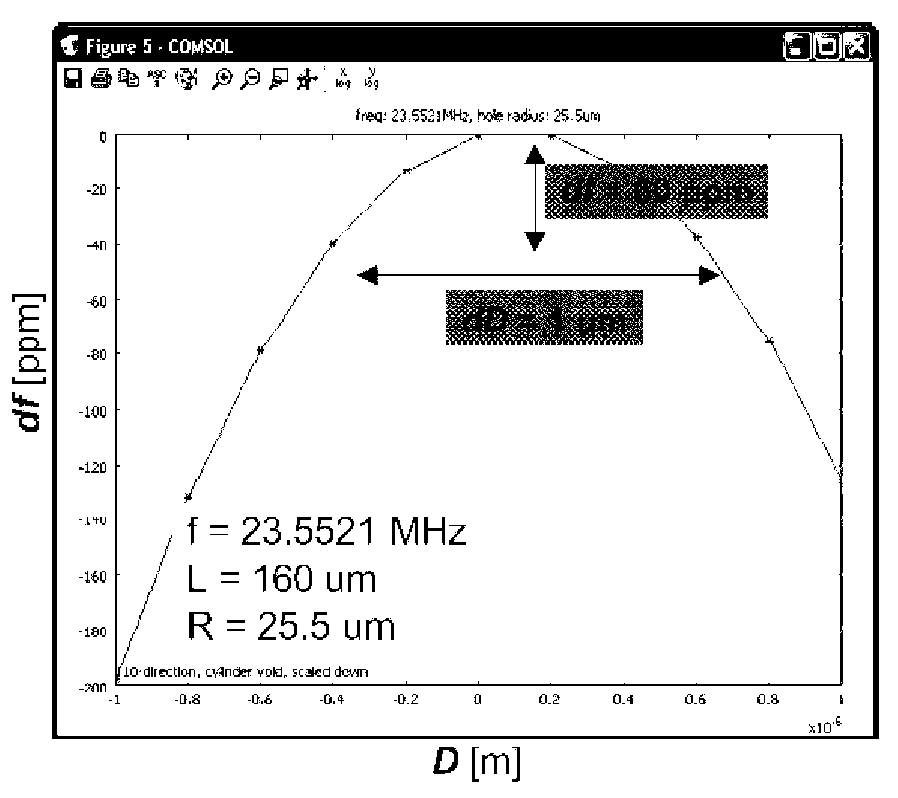

[0076] Example 2: SE plate oriented along the crystallographic direction, circular void. exist Figure 7a with Figure 7b shown in the Figure 6a with Figure 6bCorresponding results (plate size 320 μm and 160 μm).

example 3

[0077] Example 3: SE plate oriented along the crystallographic direction, with rectangular voids. exist Figure 8 The results for a plate size of 320 μm are shown in .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com