Workpiece guide device of steel plate blanking unit

A technology for guiding devices and workpieces, applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve problems such as low work efficiency, affecting feeding, production accidents, etc., to save manpower, reduce shoveling force, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

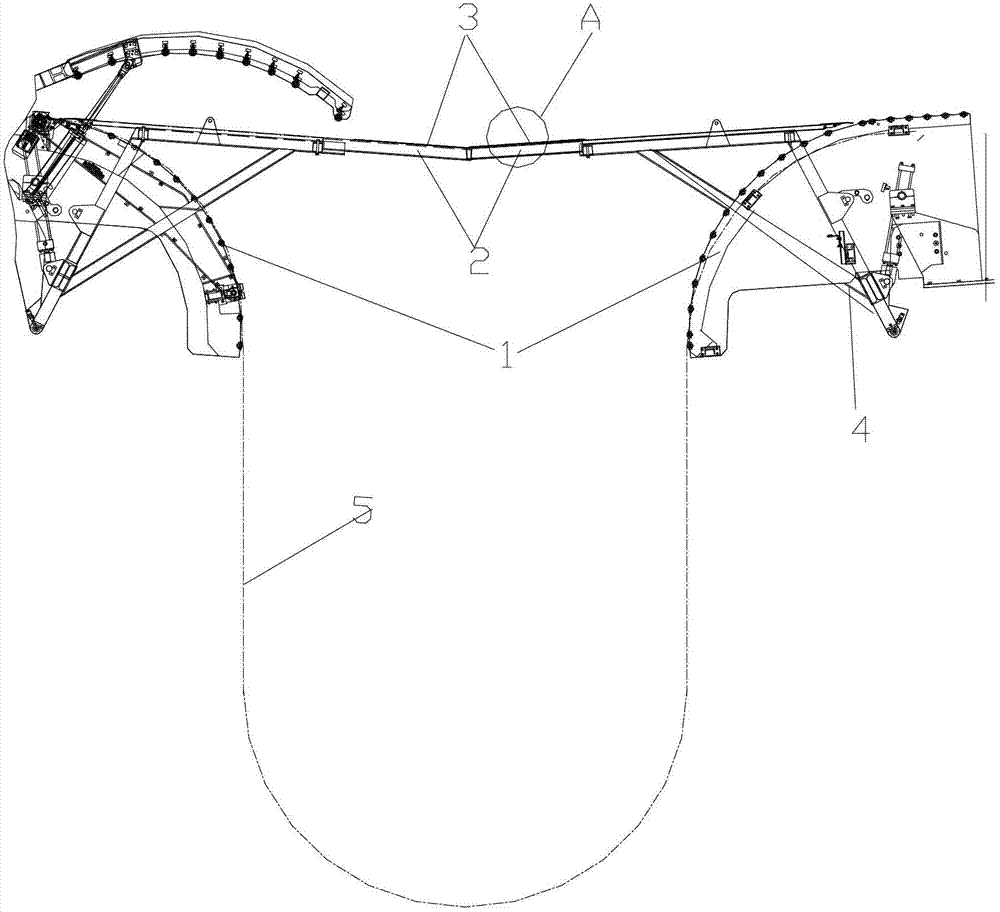

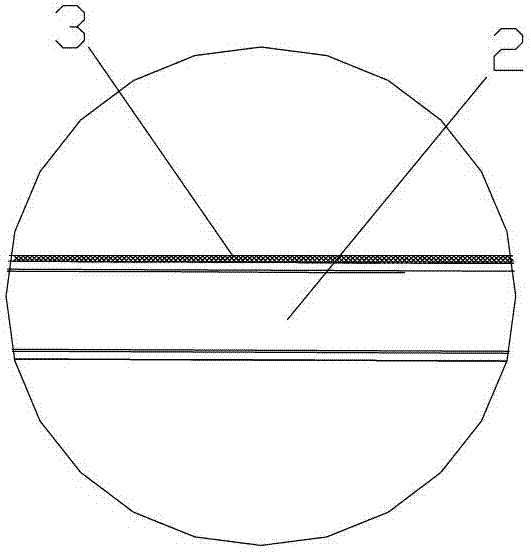

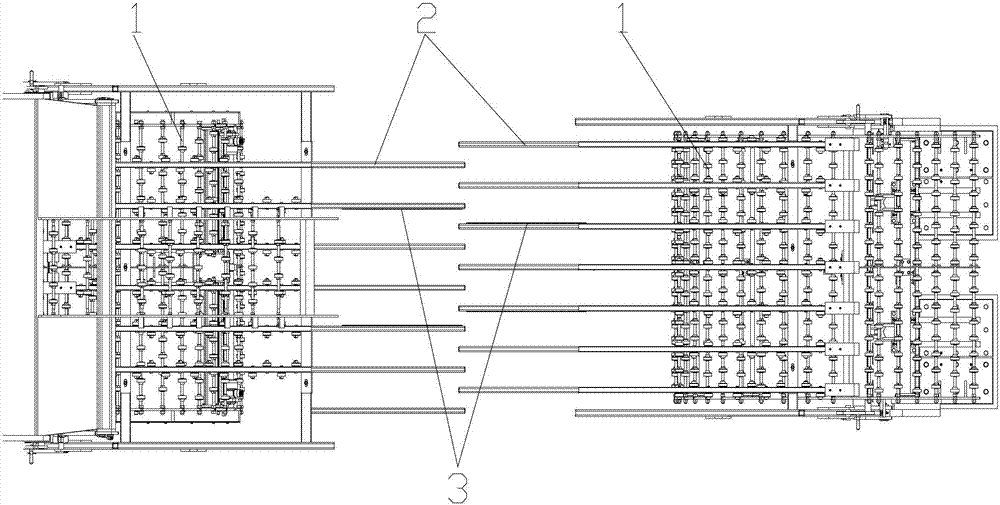

[0021] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 Enlarged view at A, image 3 It is a top view of the present invention, as shown in the figure: the workpiece guiding device of the steel plate blanking unit of this embodiment includes two curved rails 1 that are convex and downward, and the two curved rails 1 are arranged opposite to each other and transported on the workpiece 5. Directly connect the linear rails for conveying workpieces, that is, they are arranged symmetrically in the longitudinal direction; a distance is formed between the two arc-shaped rails 1 to make the workpiece 5 droop in a U-shape; as shown in the figure, the arc-shaped rails 1 are arranged oppositely, and the (Workpiece 5) When passing through the arc-shaped track, through mechanical control, the gravity of workpiece 5 can be used to form a U-shaped drooping structure. This structure has an automatic deviation correction function when the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com