Plastic extruding machine with intermediate filter

A plastic extruder and filter technology, which is applied in the field of plastic extruders, can solve the problems of prolonging the time interval of cleaning filters, increasing filter resistance, and difficulty in cleaning, etc., and achieves the goals of improving labor productivity, prolonging service life, and improving quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

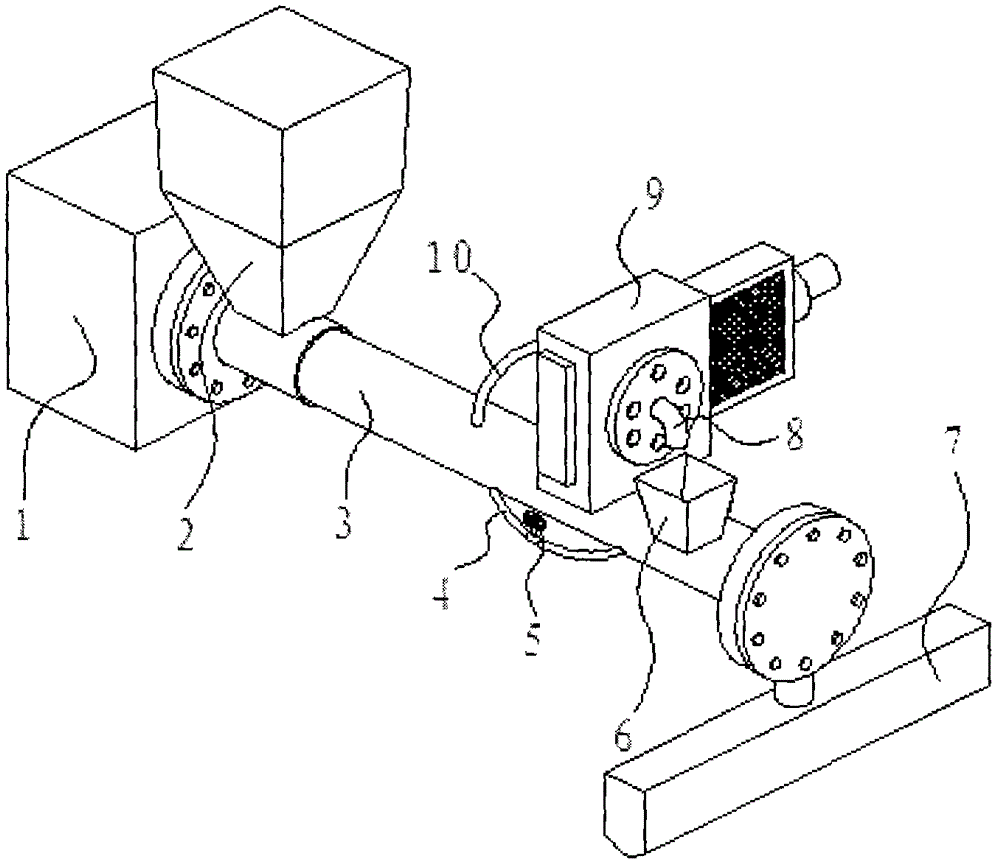

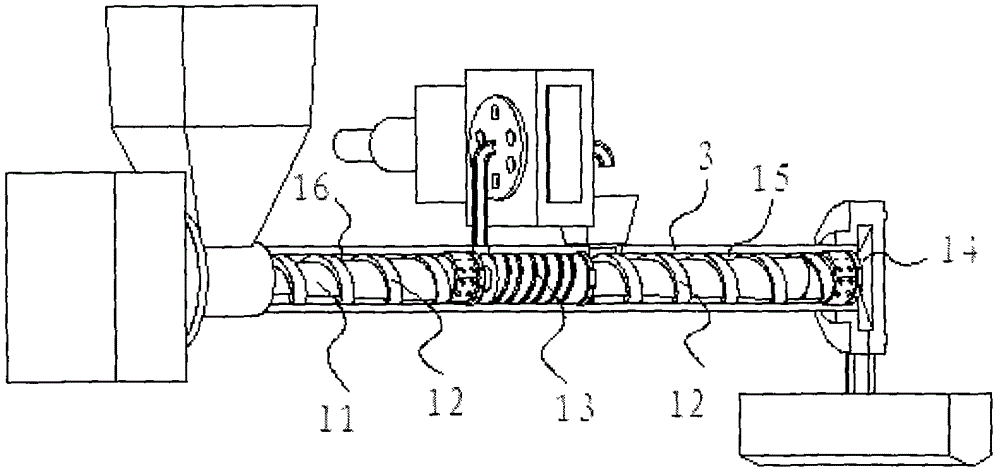

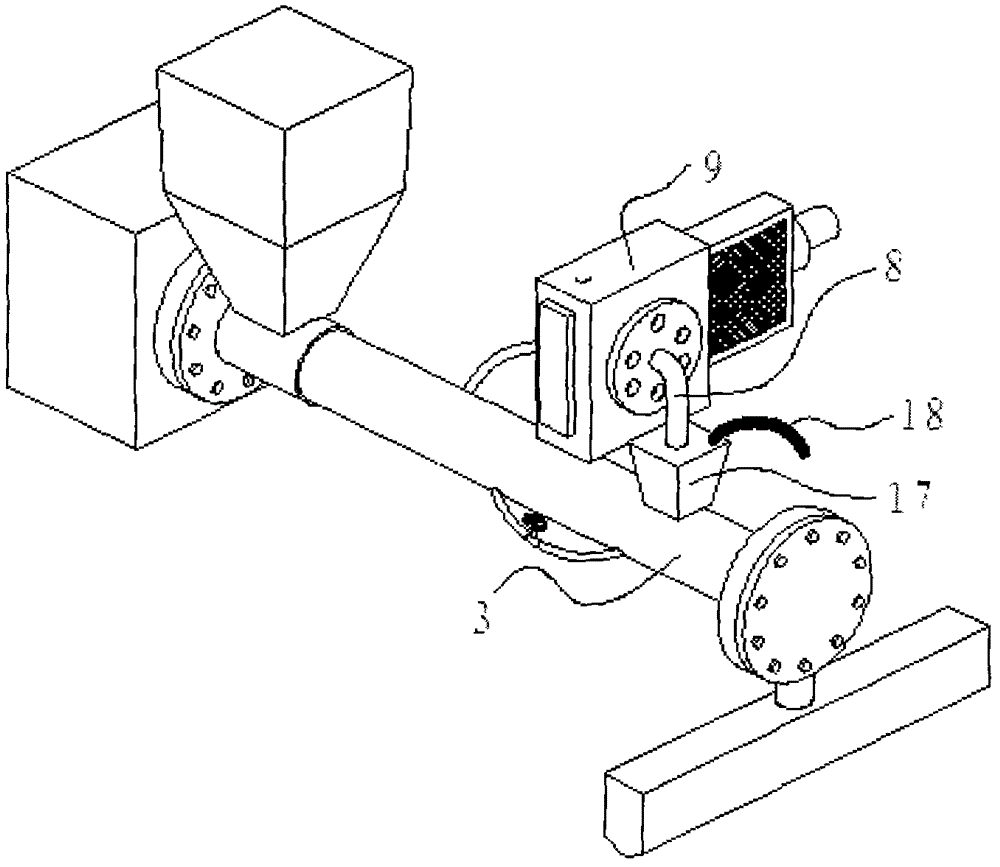

[0027] Example: A plastic extruder with an intermediate filter, such as figure 1 , figure 2 As shown in the figure: 1: driving device; 2: feed hopper; 3: barrel; 4: short-circuit pipe; 5: first stop valve; 6: receiving hopper; 7: die head; 8: discharge pipe ;9: filter device; 10: feed pipe; 11: screw; 12: main thread; 13: secondary thread; 14: filter plate; Including a hollow barrel 3, the barrel 3 is provided with a screw 11 that is rotatable relative to the barrel 3 and matched with the barrel 3, one end of the screw 11 is connected with the driving device 1, and the middle of the screw 11 is provided with a screw 11 The main thread 12 is the secondary thread 13 with the opposite helical direction. The secondary thread 13 divides the two ends of the barrel 3 into an extrusion cavity 16 and a filter cavity 15. The upper side of one end of the barrel 3 is fixedly connected with a Feeding hopper 2 and barrel 3 are fixedly connected with a die head 7 for forming and dischargi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com