Elevator steel wire rope overhauling device and overhauling method thereof

A technology for overhauling devices and wire ropes, which is applied in transportation, packaging, elevators, etc., can solve the problems of large manpower consumption, many working hours, and low safety factor, and achieve the effects of saving working hours, reducing safety risks, and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

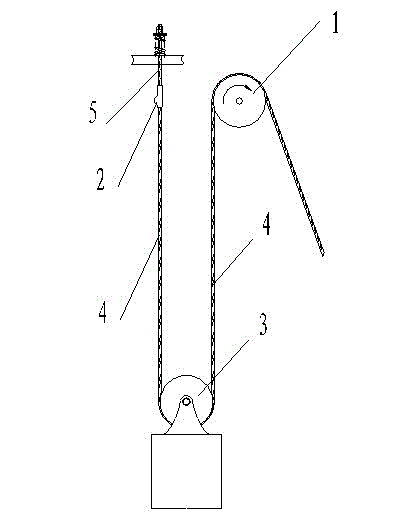

[0030] attached figure 1 It is a schematic diagram of an elevator wire rope maintenance method in the prior art. In the figure, 1 is a fixed pulley, 2 is a connecting card, 3 is a movable pulley, 4 is a wire rope, and 5 is a fixed end. As can be seen from the figure, in the prior art, the elevator wire rope maintenance method includes the following steps:

[0031] (1) Start the elevator so that the car reaches the top floor, hang the hoist on the top of the car, and prepare to lift the car;

[0032] (2) Place the special tool at the lower end of the elevator counterweight, and stop the elevator after the elevator car is lifted and the counterweight falls to the pre-placed wooden pile position; the special tool is a section of 200×200×2000 stake;

[0033] (3) According to the elongation of the steel wire rope, use a hoist to lift the car to a certain position. The position is such that the wire rope can exceed its elongation by 200 mm. The hoist is a commonly used electric li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com