Flame-retardant lifesaving blanket and production method thereof

A production method and blanket technology, which is applied in the field of flame-retardant life-saving blankets, can solve the problems of low fiber strength and large smoke, and achieve the effects of good flame-retardant performance, gorgeous luster, skin-friendly antibacterial, and excellent flame-retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

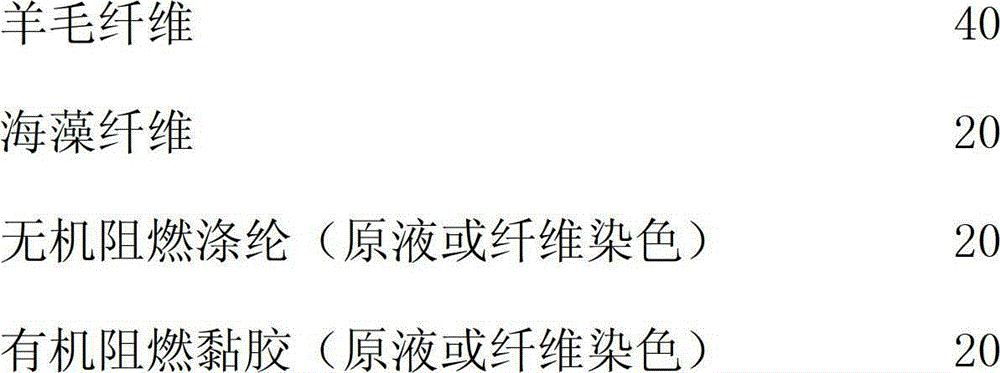

[0014] Wool, seaweed fiber and flame-retardant viscose blanket and its production method are made by blending wool, seaweed fiber and flame-retardant viscose fiber in the following percentages by weight:

[0015]

[0016] The blanket specification is: 150*200cm 550g / m 2

[0017] Warp: 300D polyester Weft: 4s wool blended fiber

[0018] The production method includes production process steps such as dyeing-spinning-weaving-finishing and shaping, wherein

[0019] Dyeing, wool fiber is dyed with loose wool, seaweed fiber and flame-retardant viscose fiber are dyed with natural color fiber. When dyeing seaweed fiber, first put the seaweed fiber into warm water at 50°C for 30 minutes, and then use weak acid dyes. Dyeing at 85°C for 40 minutes, pH value of 3.5, and bath ratio of 1:20; dyeing of flame-retardant viscose fibers at bath ratio of 1:50, temperature of 65°C, and time of 40 minutes .

[0020] The moisture regain in spinning is controlled at 13%, the relative humidity ...

Embodiment 2~ Embodiment 6

[0034] According to the method and steps of Example 1, it is made by blending wool fiber, seaweed fiber, organic flame-retardant viscose, and inorganic flame-retardant viscose according to the following weight percentages: 60 / 40 / 0 / 0, 30 / 10 / 30 / 30, 40 / 20 / 20 / 20, 30 / 40 / 30 / 0, and 30 / 40 / 0 / 30 are basically the same as in Example 1 through the product technical indicators tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com