Hand tufted blanket knitting machine

A technology of carpet weaving machine and gun stabbing, which is applied in the field of self-made high-efficiency manual gun stabbing blanket weaving machine, which can solve the problems of inconvenient use for operators, low work efficiency and high price, and achieve light weight, high production efficiency and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

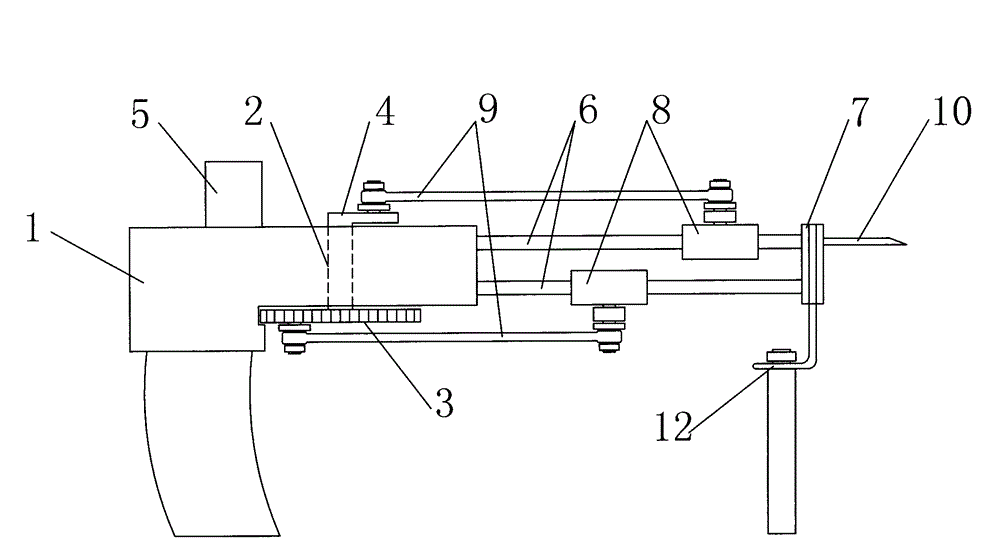

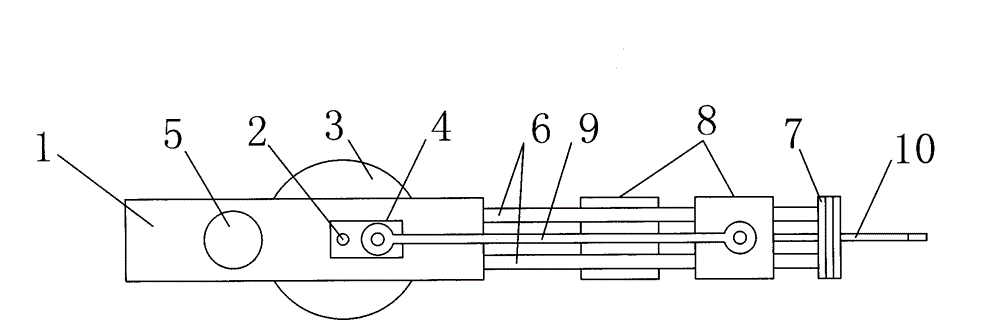

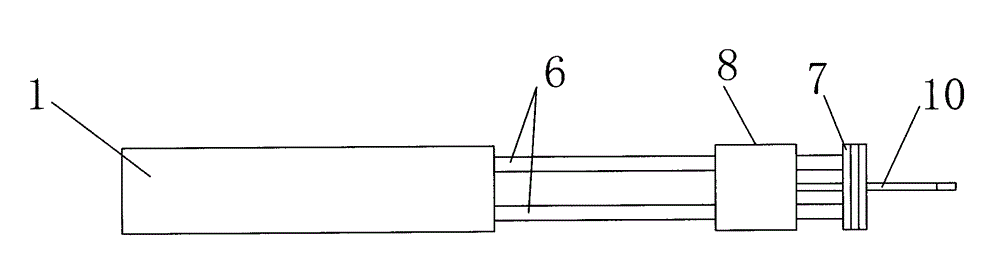

[0015] As shown in the figure, the manual gun stabbing carpet weaving machine includes a gun body 1, a short shaft 2 is installed in the middle of the gun body 1, a wheel 3 is installed on the bottom of the short shaft 2, a curved rod 4 is installed on the top, and a driving wheel 3 is installed on the gun body 1. Motor 5, the front end of gun body 1 establishes two rows of guide rails 6 that are juxtaposed up and down, the head of guide rail 6 installs headstock 7, slide block 8 is all established on each guide rail 6, and curved bar 4 is connected with upper slide block by linkage bar 9 8 are connected, and the eccentric position of the wheel disc 3 is also provided with the linkage bar 9 connected with the lower slider 8, the middle part of the upper slider 8 is equipped with a spatula 10, and the middle part of the lower slider 8 is equipped with a knitting needle 11, and the spatula 10 and the knitting needle are connected with each other. The needle 11 can penetrate the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com