Construction method for sand-filling subgrade

A construction method and subgrade technology, applied in roads, roads, buildings, etc., can solve problems such as filler characteristics, road performance gaps, lack of effective practical experience, limited engineering cases, etc., to achieve good overall stability, good connection, The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

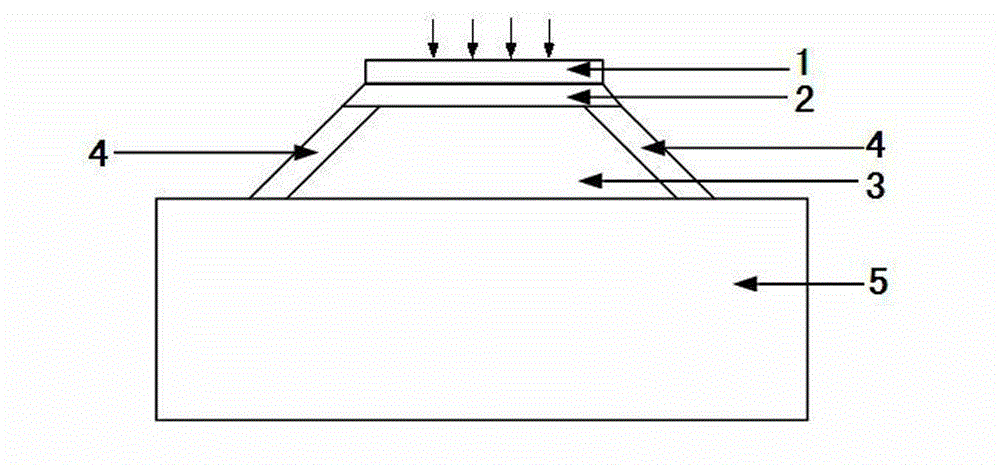

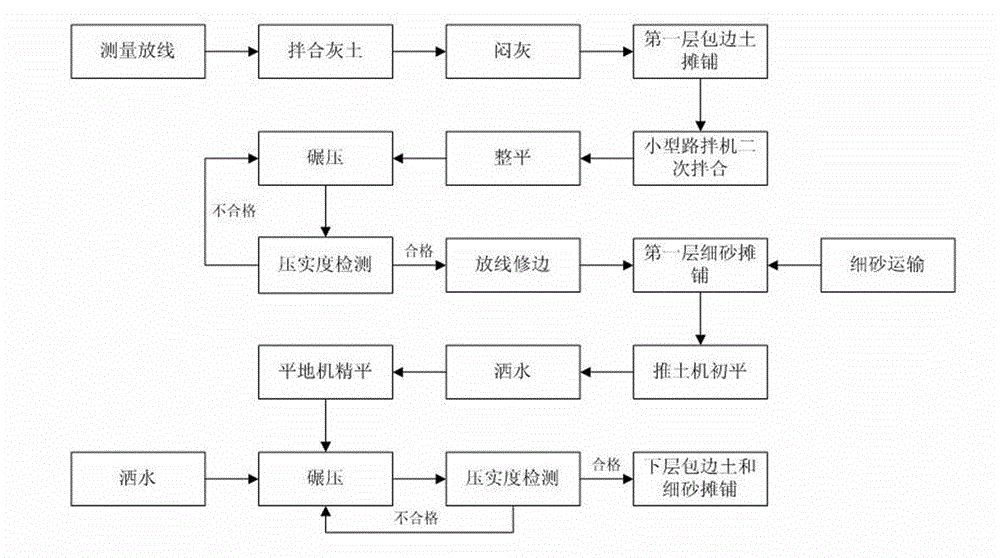

[0031] Embodiment: the processing and production process of the present embodiment is as follows:

[0032] 1. Cleaning and removal of subgrade topsoil

[0033] According to the requirements of the construction specification, the topsoil of subgrade 5 shall be removed with bulldozers before construction, and the weeds, tree roots and humus soil on the original ground shall be removed beyond the range of subgrade 5. Clear topsoil should be piled on one side as much as possible (the other side is used as a construction access road) for green use. In the process of clearing the surface, if there are situations such as bright bangs and dark bangs, it should be handled according to the design documents, and subsequent construction can only be carried out after meeting the requirements. After the table cleaning is completed, the pre-fill rolling is carried out in an all-round way.

[0034] 2. Set up drainage system

[0035] The drainage system at the bottom of subgrade 5 shall be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com