Cutting device of coal cutter

A shearer, drum technology applied to cutting rods. It can solve the problems that affect the amount of undercover, cannot meet the needs of thin coal seam or thin coal seam mining, low transmission efficiency, etc., and achieve the effect of solving the problem of coal loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

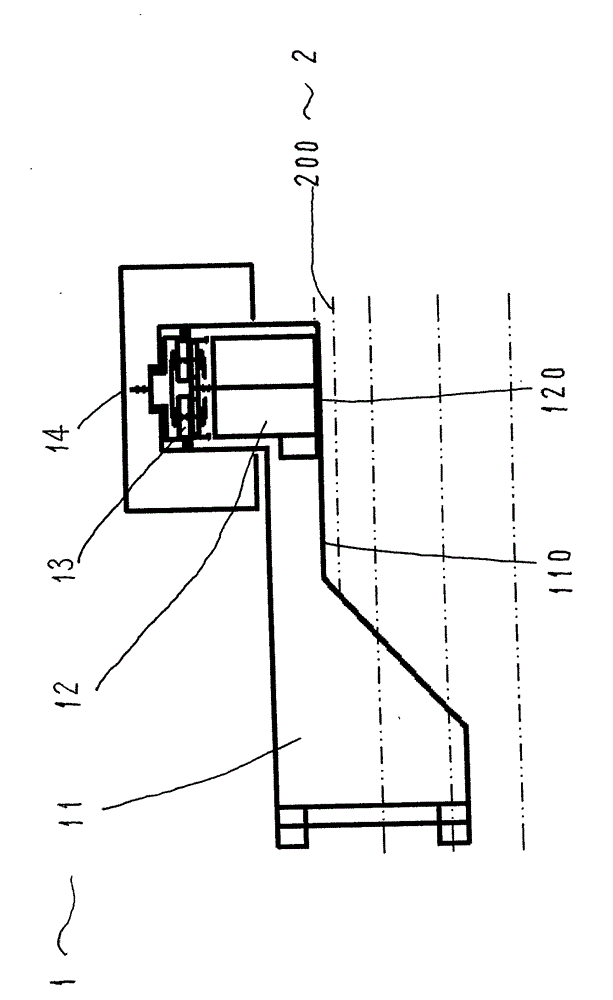

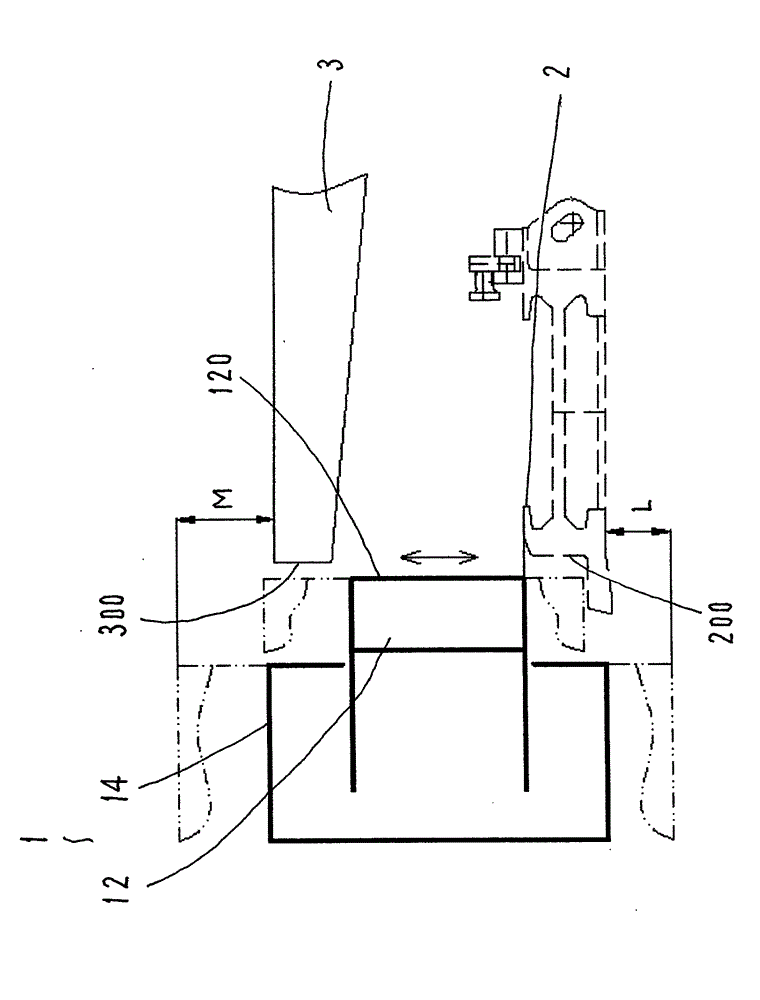

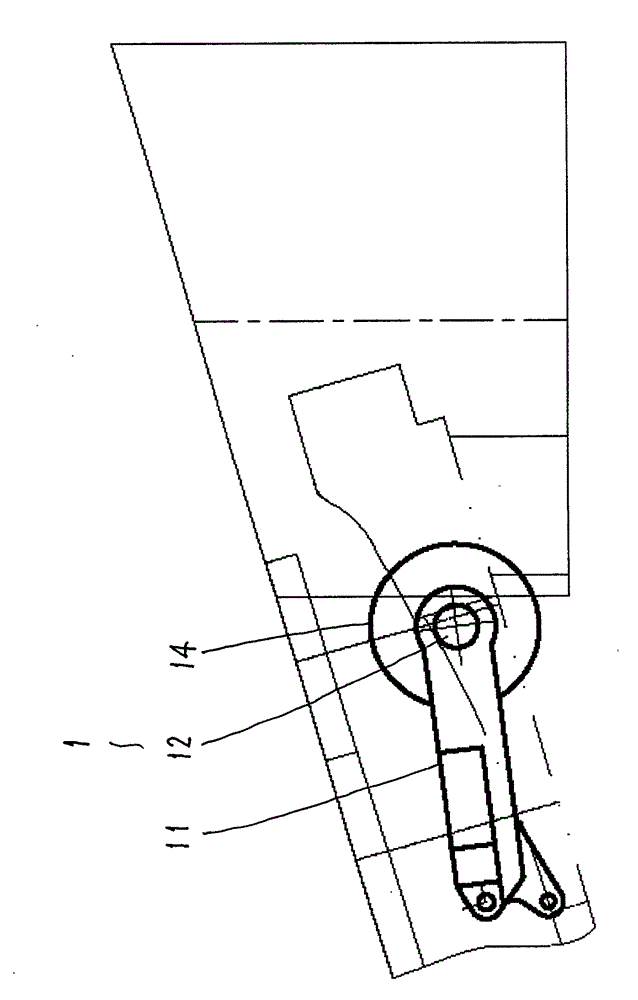

[0016] refer to figure 1 , 2 , 3. The shearer cutting device 1 includes a casing 11 , a motor 12 , a planetary gear train 13 and a drum 14 .

[0017] The housing 11 is the main component of the cutting device 1, and each component part of the device is installed on the housing 11. The structure of the housing 11 is basically similar to that of the prior art. Body 11 can be formed into a narrower structural shape.

[0018] The motor 12 has the same structure as the prior art, and the feature of the present invention is that the motor 12 is accommodated in the inner chamber of the drum 14 along the axial direction, such as figure 1 As shown, the extended end wire 120 on the side near the groove side 2 of the motor 12 is flush with the rocker arm side 110 of the housing 11 after the motor 12 is installed, so the outer end wire 120 on the side near the groove side 2 of the motor 12 and There is a gap between the edge line 200 on the side near the cylinder 14 of the groove sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com