Simulation braking bench for automobile disc brake

A disc brake and brake test technology, which is applied in vehicle testing, machine/structural component testing, instruments, etc., can solve problems such as inaccurate data measurement, low degree of automation, and small simulated inertia, so as to achieve reliable detection data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the drawings.

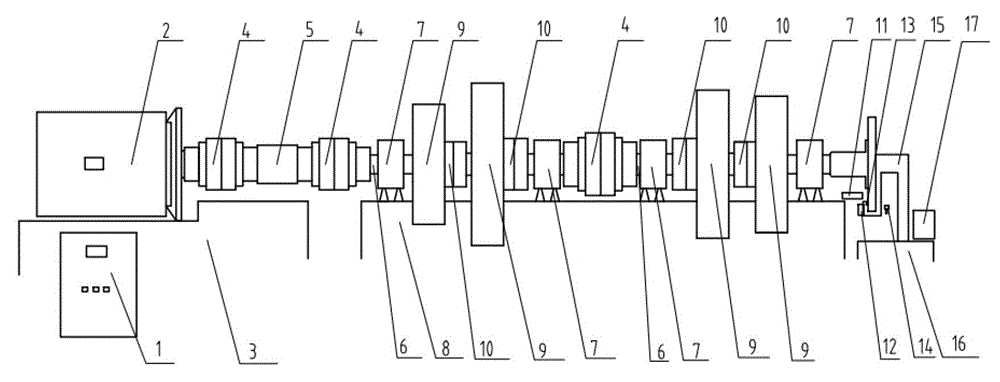

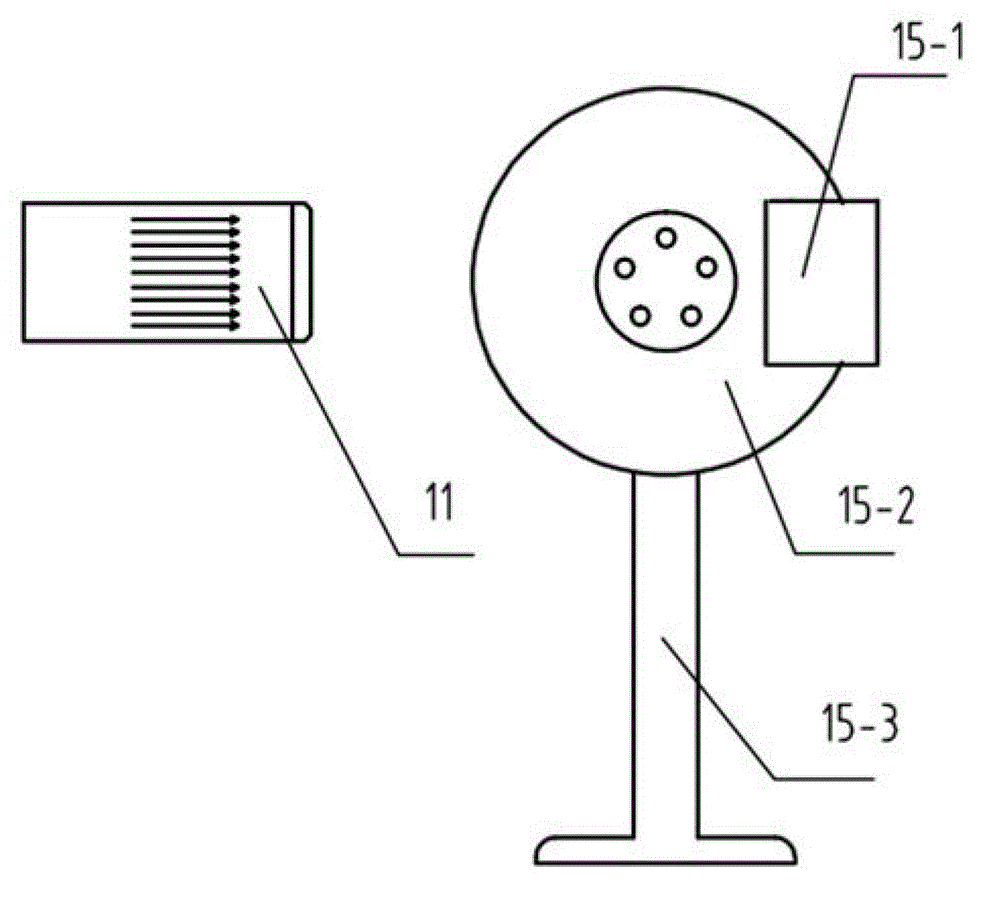

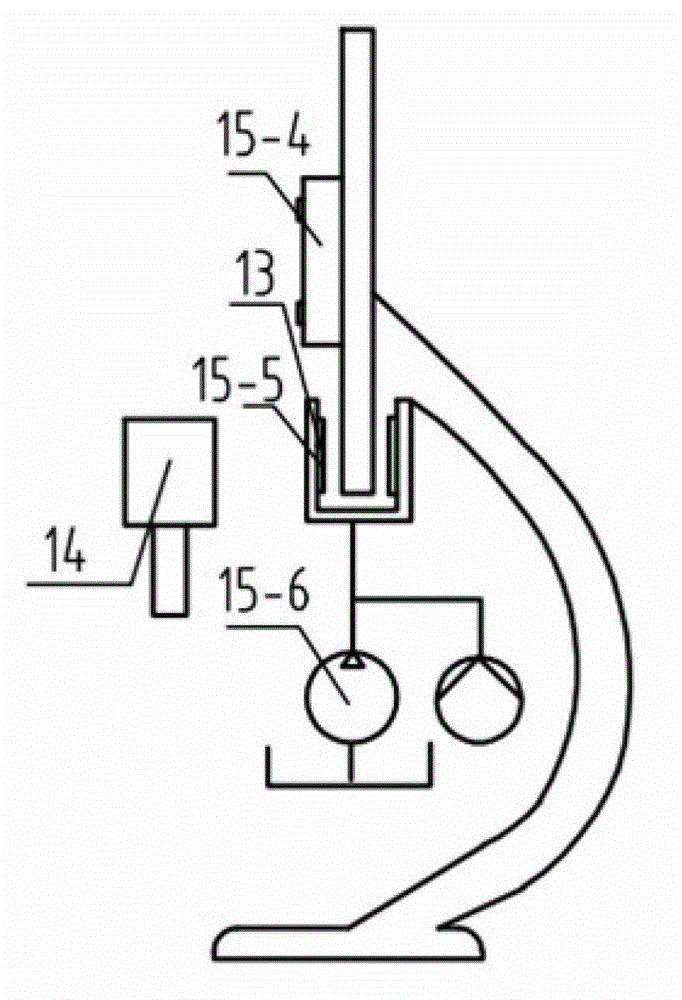

[0015] Such as figure 1 As shown, this automobile disc brake simulation brake test bench includes frequency converter 1, frequency conversion motor 2, elastic pin coupling 4, torque and speed sensor 5, main shaft 6, bearing seat 7, flywheel 9, and jaw The electromagnetic clutch 10 and the braking system 15, the frequency converter 1 is connected with the frequency conversion motor 2, and the frequency conversion motor 2 and the torque speed sensor 5 are connected by an elastic pin coupling 4 and fixed on the left platform 3, two main shafts 6 is fixed on the middle platform 8 by four bearing seats 7. The main shaft 6 is connected with the torque and speed sensor 5 and the two main shafts 6 through the elastic pin coupling 4, the flywheel 9 is arranged on the main shaft 6, and the four Two flywheels 9 are distributed between the bearing seats 7, two flywheels 9 are arranged between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com