Method and device for fatigue test crack diagnosis of engine body

An engine body and fatigue test technology, applied in the field of test diagnosis, can solve problems such as errors in fatigue limit values, affecting the company's judgment on the reliability of the engine body, and inaccurate fatigue life results of the engine body, so as to achieve the effect of improving precision and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

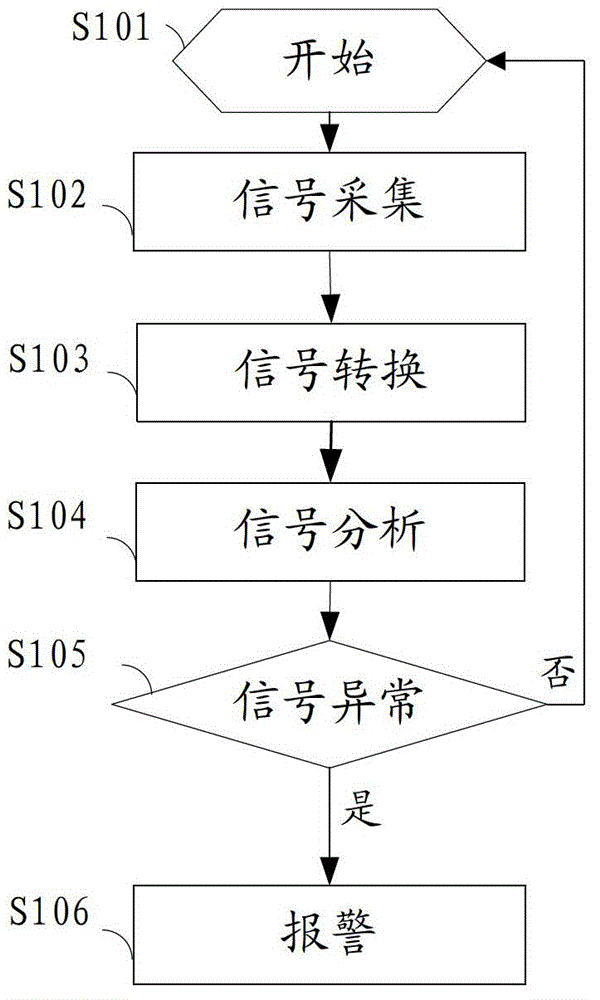

[0040] see figure 1 , which is a flow chart of a method for diagnosing cracks in an engine body fatigue test of the present invention, the method comprising the following steps:

[0041] S101: Start engine body fatigue test.

[0042] S102: the strain gauge and the acceleration sensor respectively collect strain signals and vibration signals of the engine body in the fatigue test.

[0043] S103: The data acquisition card converts the strain signal and the vibration signal into digital signals respectively, and sends the strain signal and the vibration signal converted into digital signals to the industrial computer.

[0044] S104: The industrial computer collects multiple discrete signals from the strain signals and vibration signals converted into digital signals, performs wavelet analysis on the multiple discrete strain signals collected, monitors the signal singularity of the analysis results, and analyzes the collected multiple discrete The vibration signal is subjected t...

Embodiment 2

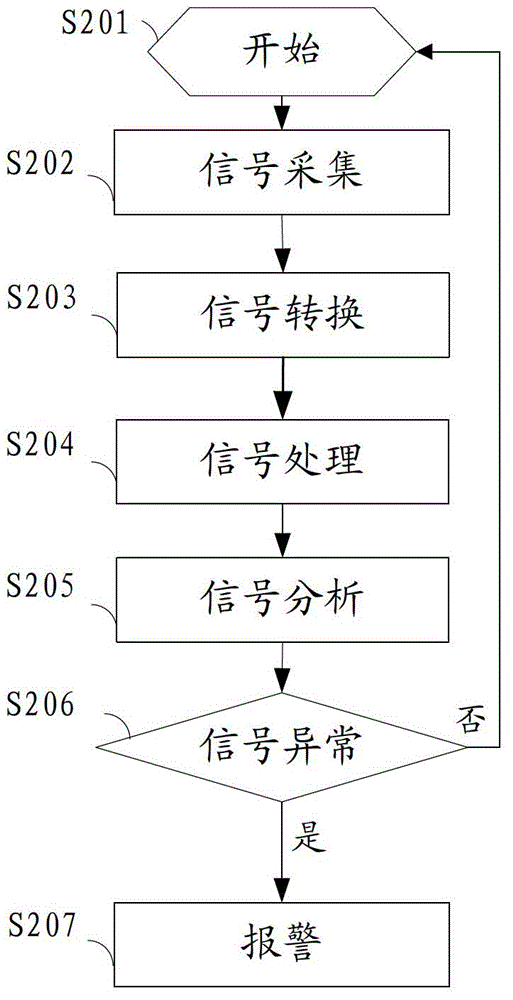

[0053] see figure 2 , which is another flowchart of a method for diagnosing cracks in an engine block fatigue test of the present invention, the method also includes the following steps:

[0054] S201: Start the engine block fatigue test.

[0055] S202: The strain gauge and the acceleration sensor respectively collect strain signals and vibration signals of the engine body in the fatigue test.

[0056] S203: The data acquisition card converts the strain signal and the vibration signal into digital signals respectively, and sends the strain signal and the vibration signal converted into digital signals to the industrial computer.

[0057] S204: The industrial computer performs pasteurized low-pass filtering processing on the strain signal converted into a digital signal, and performs wavelet denoising processing on the vibration signal converted into a digital signal to remove false components.

[0058] What needs to be further explained in step S204 is that the preferred wa...

Embodiment 3

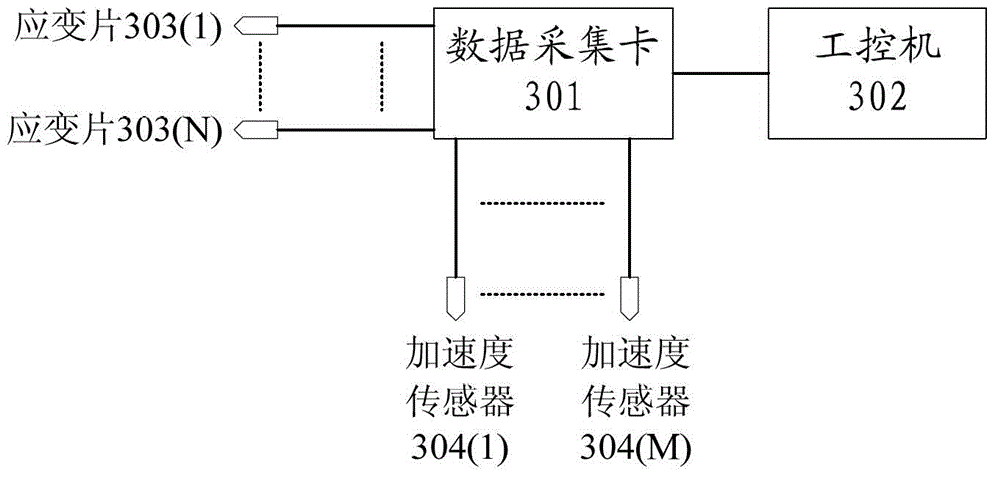

[0066] see image 3 , which is a system structure diagram of an engine body fatigue test crack diagnosis device of the present invention, including a data acquisition card 301, an industrial computer 302, strain gauges 303(1) to 303(N) and an acceleration sensor 304(1) To the acceleration sensor 304 (M), wherein N and M are integers greater than or equal to 1,

[0067] The strain gauges 303(1)-303(N) are used to collect the strain signal of the engine in the fatigue test;

[0068] The acceleration sensors 304(1)-304(M) are used to collect vibration signals of the engine in the fatigue test;

[0069] The data acquisition card 301 is connected to the strain gauges 303(1)-303(N) and the acceleration sensors 304(1)-304(M), and is used to convert the strain signals and vibration signals into digital signals respectively, and sending the strain signal and vibration signal converted into digital signals to the industrial computer.

[0070] The industrial computer 302 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com