LCD (Liquid Crystal Display) device and manufacturing method thereof

A liquid crystal display device and one-sided technology, which are applied in the directions of instruments, nonlinear optics, optics, etc., can solve the problems of complex structure and high cost of liquid crystal display devices, and achieve the effects of reducing deformation, simplifying structure, and improving product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

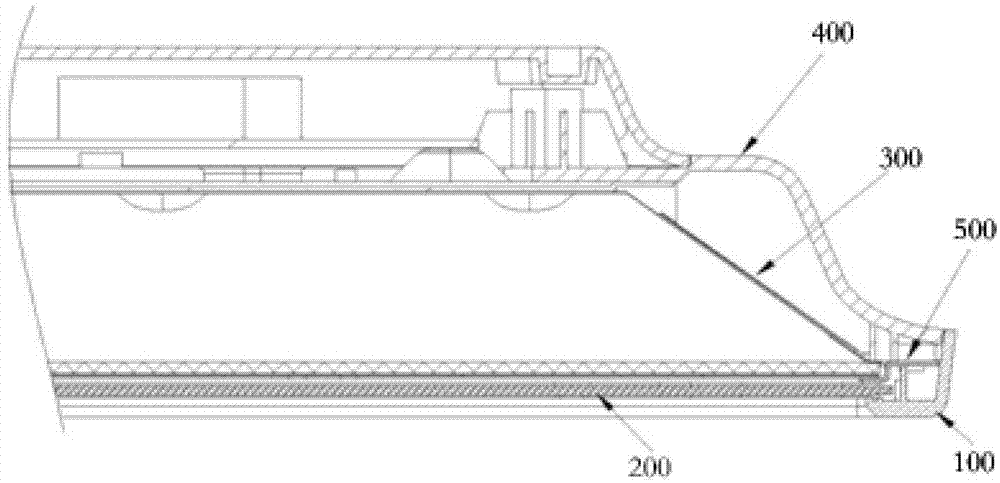

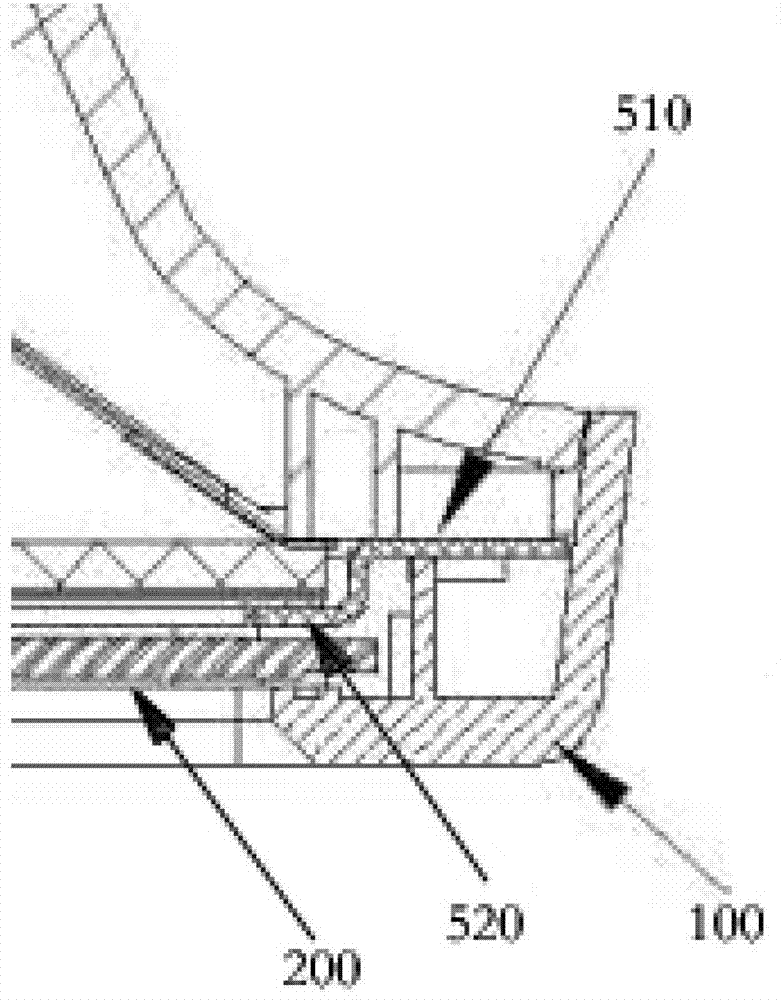

[0057] In the embodiment of the present invention, the connection between the bracket 500 and the front shell 100 is as follows Figure 5As shown, the connection between the bracket 500 and the rear shell assembly 400 is as follows Figure 6 shown. In this embodiment, screws are used to connect with the rear shell assembly 400 through screw holes in the upper horizontal plate 510 of the bracket 500 . The end of the upper horizontal plate 510 facing the outside of the bracket 500 is connected to the front shell 100 through a bayonet. The bracket 500 used in this embodiment is a sheet metal bracket.

[0058] Wherein, the front case 100 not only has the function of the front case in the traditional sense, but also has the function of the front frame in the liquid crystal screen component of the liquid crystal display device in the prior art, and can support the liquid crystal panel 200 . The sheet metal bracket 500 serves to fix the liquid crystal panel 200 , and since the she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com