Variable frequency control dynamic liquid level experiment equipment

A technology of frequency conversion control and experimental equipment, applied in the direction of electrical program control, sequence/logic controller program control, instruments, etc., can solve the problems of increasing the resource allocation cost of schools and training institutions, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

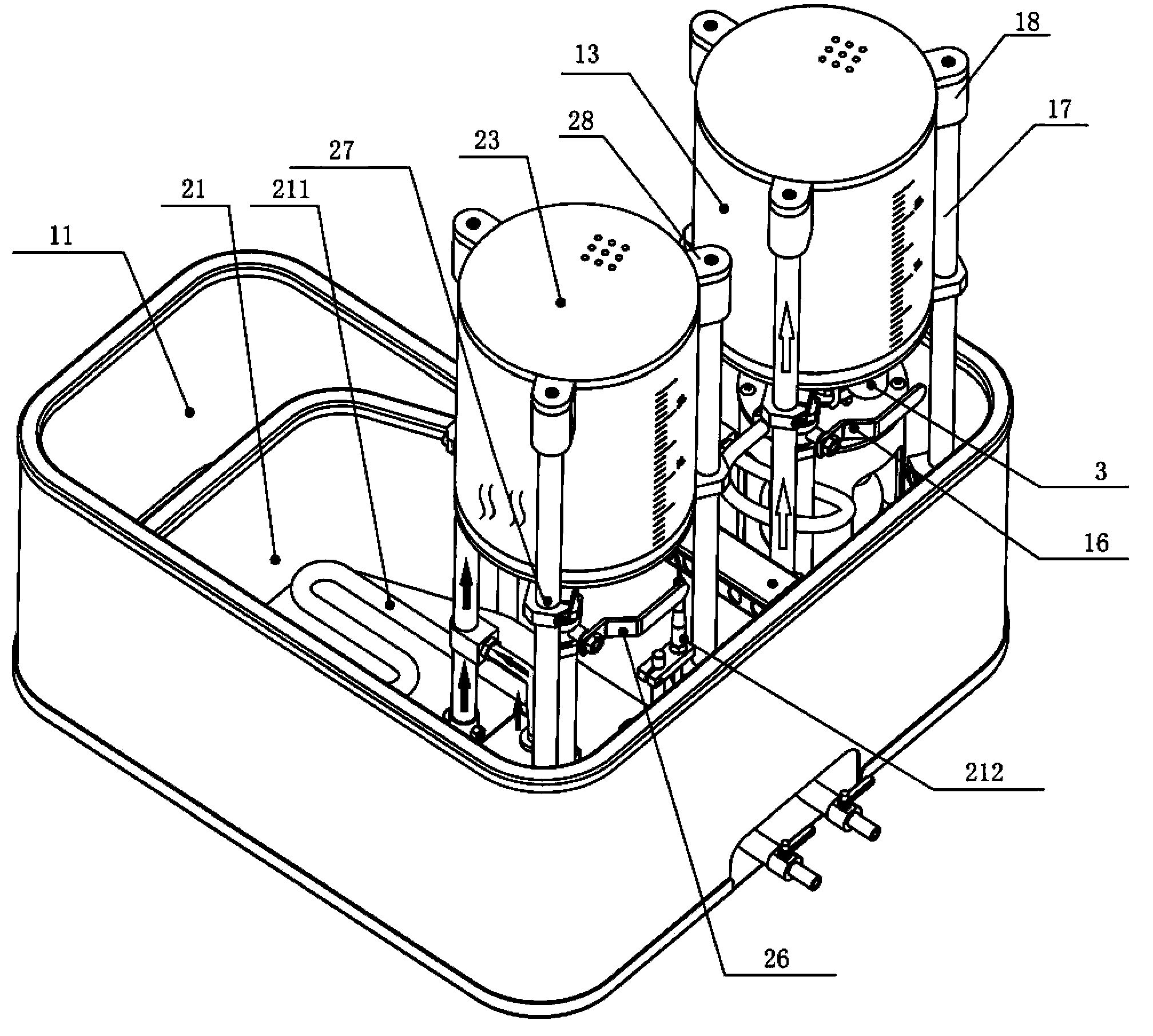

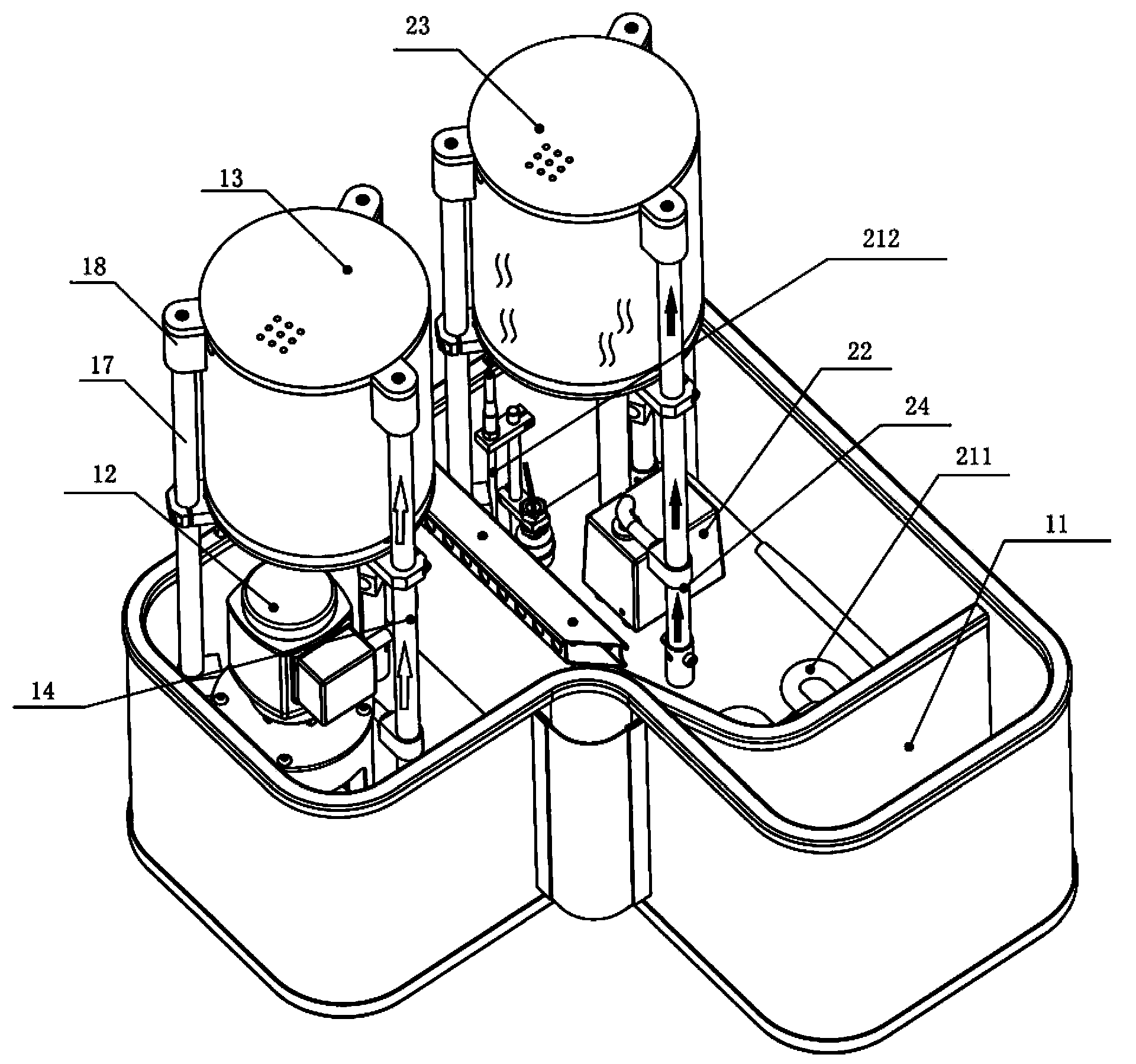

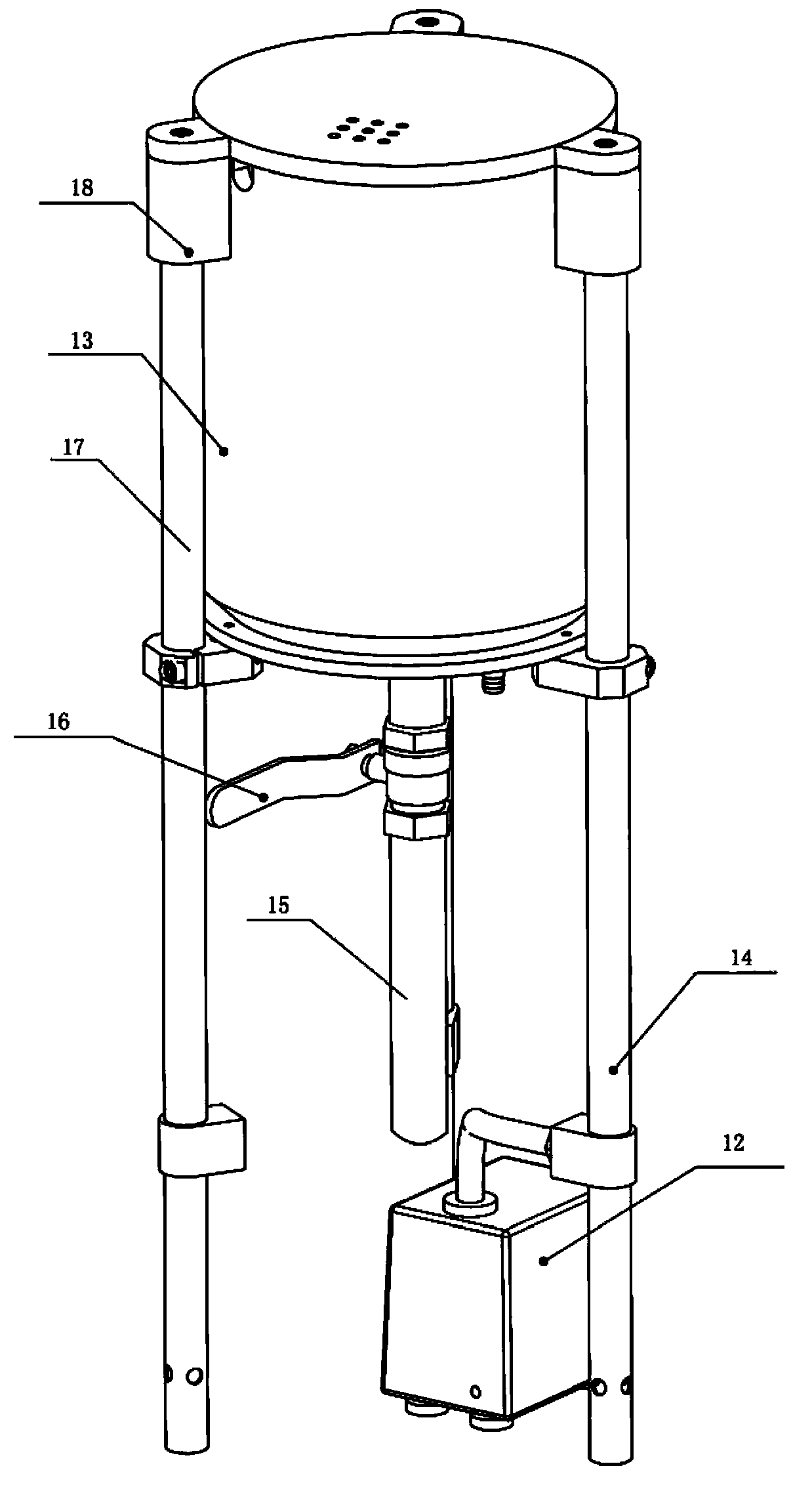

[0030] Such as Figure 1 to Figure 4 As shown, the frequency conversion control dynamic liquid level experimental equipment of the present invention comprises a constant pressure water tank 11, a constant pressure tank device, a first submersible pump 12, a water pressure detection device 3 for detecting the water pressure in the constant pressure tank device, and uses PID algorithm program to control the PLC frequency conversion control circuit (not shown in the figure) of the first submersible pump 12, the constant temperature water tank 21, the constant temperature tank device, the second submersible pump 22 and the constant temperature heating for constant temperature heating of the water inside the constant temperature water tank 21 device; the first submersible pump 12 is located in the inside of the constant pressure water tank 11; the constant pressure tank device includes a constant pressure tank 13 for filling water and a first first connected with the constant pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com