Piezoelectric variable-frequency contact type liquid level switch

A liquid level switch, contact type technology, applied in the field of piezoelectric frequency conversion contact type liquid level switch, can solve the problems of poor performance of liquid level switch, poor control liquid level accuracy, large volume of liquid level switch, etc., to broaden the scope of application , less man-hours, simple circuit board structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

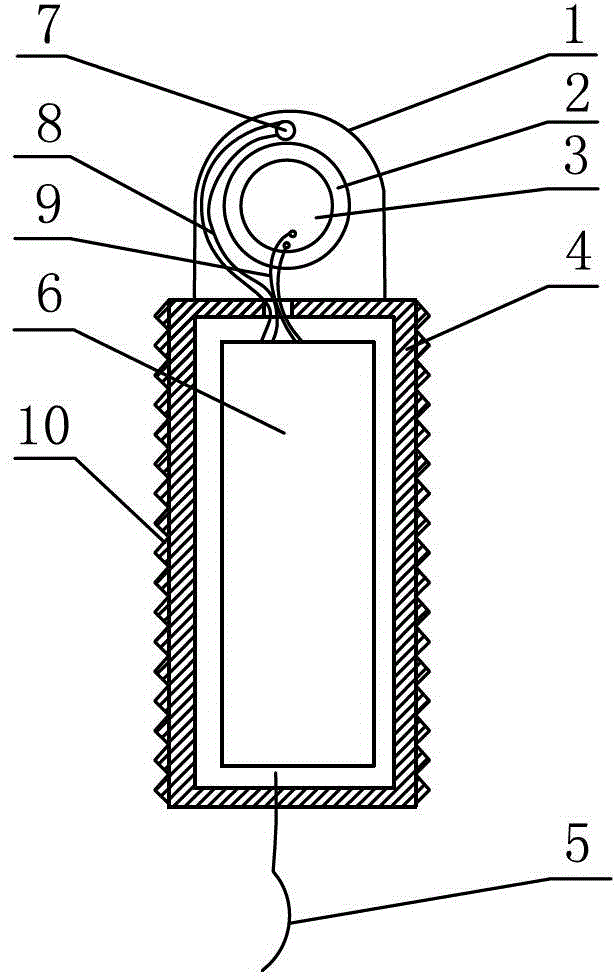

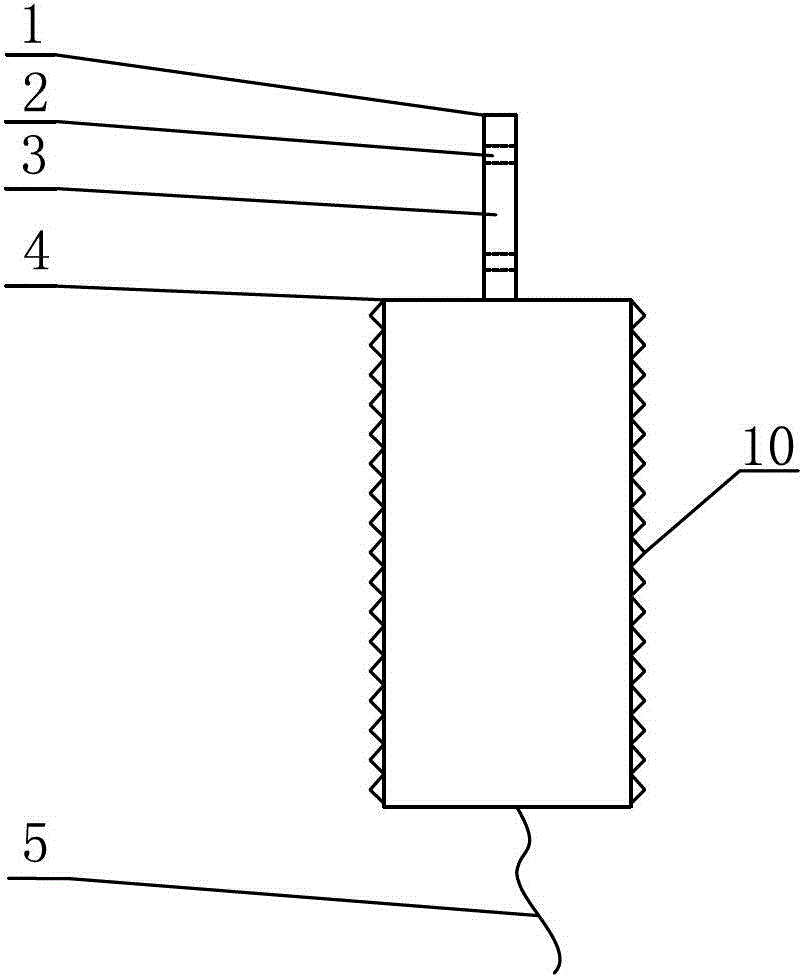

[0027] Such as figure 1 As shown, one end of the barrel 4 is provided with a probe bracket 1, and the probe bracket 1 is fixed with a piezoelectric ceramic sheet 3 (JZ) and a thermistor 7 (RT). 1. Connect the circuit board 6 arranged in the barrel 4 . The probe bracket 1 is provided with an installation hole, the piezoelectric ceramic sheet 3 is arranged in the installation hole, and the thermistor 7 is arranged on the probe holder 1 on the upper edge of the piezoelectric ceramic sheet 3 . The barrel 4 is provided with an external thread 10 for installation. Electronic potting glue is arranged in the gap between the circuit board 6 and the cylinder body 4 . The circuit board 6 is provided with an external cable 5 .

[0028] The outer surfaces of the probe holder 1 and the piezoelectric ceramic sheet 3 are respectively provided with insulating paint layers.

[0029] The probe holder 1 and the piezoelectric ceramic sheet 3 are covered with an elastic and durable rubber layer...

Embodiment 2

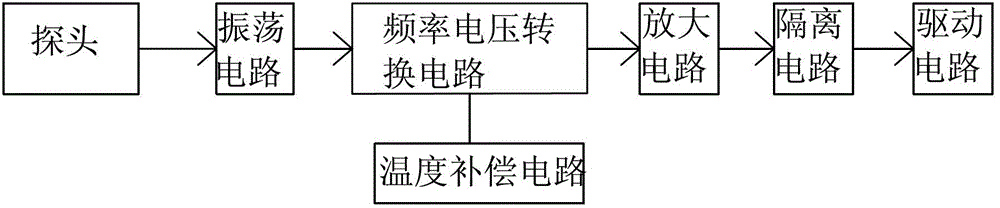

[0049] The amplifying circuit adopts an integrated operational amplifier, and the thermistor is connected to the integrated operational amplifier for temperature compensation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com