Production line for curing solar cell module and method for curing solar cell module

A technology of solar battery components and battery components, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low production efficiency, low equipment utilization rate, and inability to realize fully automated production, and achieve high production efficiency and equipment utilization rate High, to achieve the effect of fully automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

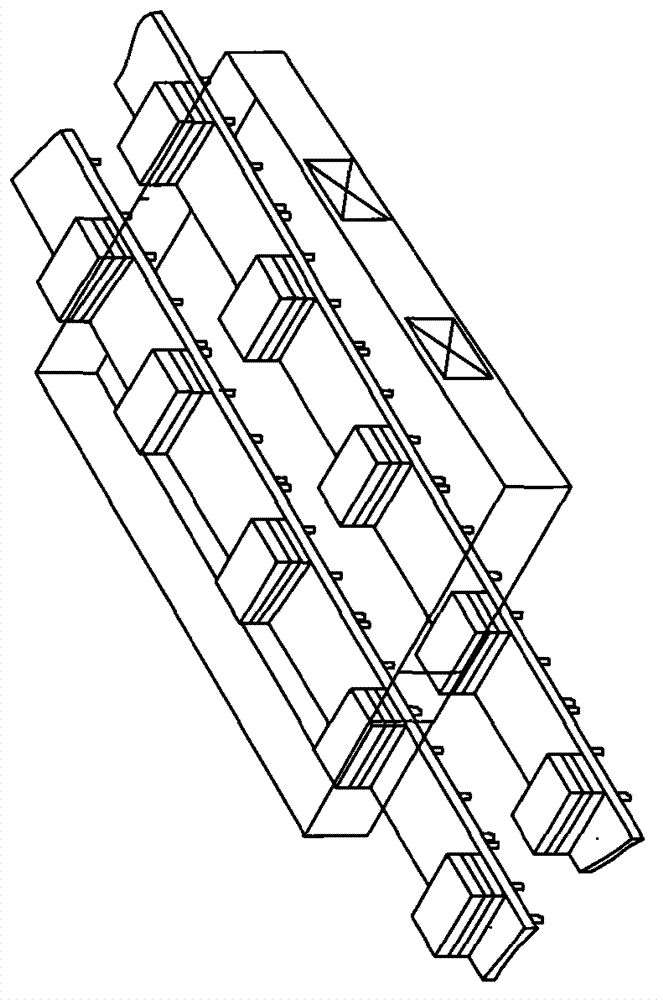

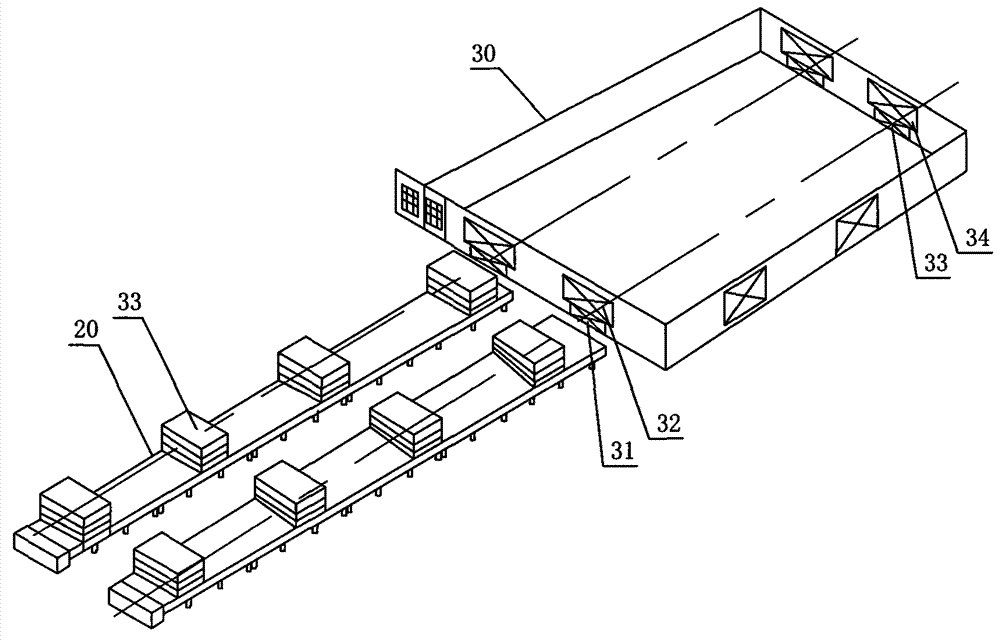

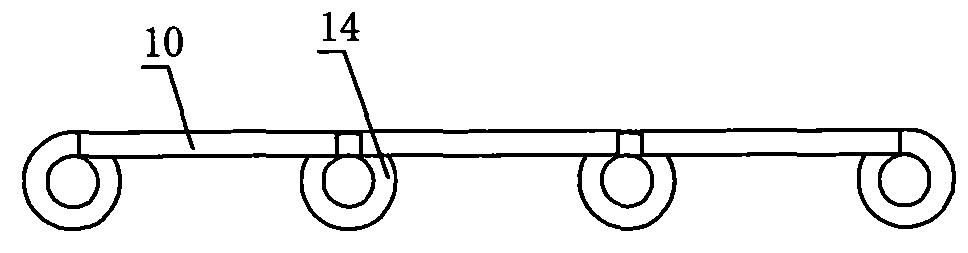

[0026] like figure 1 , 2 , 3a, 3b, 3c, 4, and 5, the solar cell module curing production line of the present invention is composed of a curing conveyor line 20 and a curing room 30, and a temperature control device, a humidity control device and an exhaust device are arranged in the curing room 30, The front wall and the rear wall of the curing room are all provided with conveying line passages 31, which correspond to the conveying line passages 31 located on the front wall and the rear wall; a conveying port 32 is arranged above each conveying line passage, each The conveying port 32 is provided with a conveying door, and the conveying door is preferably a fast rolling door; the curing conveying line can be an existing common battery assembly conveying line, and the curing conveying line runs through the curing room through the conveying line channel 31, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com