Automatic weighing vacuum liquid injection system for power battery, and liquid injection method thereof

An automatic weighing and power battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of inaccurate liquid injection, difficult liquid injection, complicated operation, etc., to achieve accurate liquid injection, cost-effective Inexpensive, flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

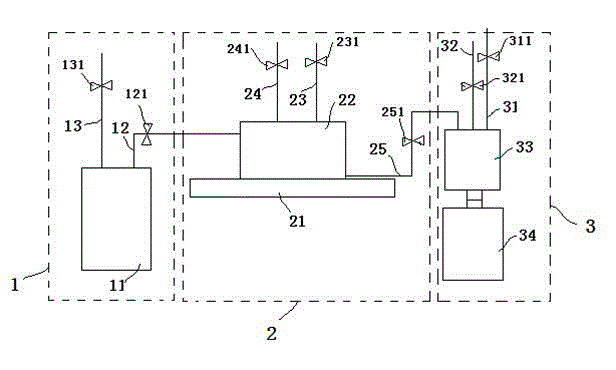

[0029] The present invention will be further explained below in conjunction with the drawings:

[0030] figure 1 It shows a schematic structural diagram of an automatic weighing vacuum liquid injection system for a power battery, which is a preferred embodiment of various embodiments of the present invention. Including the liquid storage inlet module 1, the weighing module 2, the liquid injection module 3 and the control module; the liquid storage inlet module 1 stores the electrolyte to be injected, and when the injection is needed, the electrolyte is passed through the conveying pipe under the action of positive pressure Road transport to the weighing module. The weighing module 2 limits the weight of the electrolyte entering the weighing module, and the volume of each injection can be adjusted by adjusting the upper limit of the weighing. The lower end of the liquid injection module 3 is connected to the battery liquid injection hole. The vacuum injection method is used to v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com