Long-axis tooth-shaped cold extruding self-ejecting system device

A system device and cold extrusion technology, which is applied in the field of long-axis tooth-shaped cold extrusion self-ejection system device, can solve the problems of large mold size, inconvenient parts removal, and small size, so as to realize automatic production , Easy to take out the parts, and the effect of small device appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

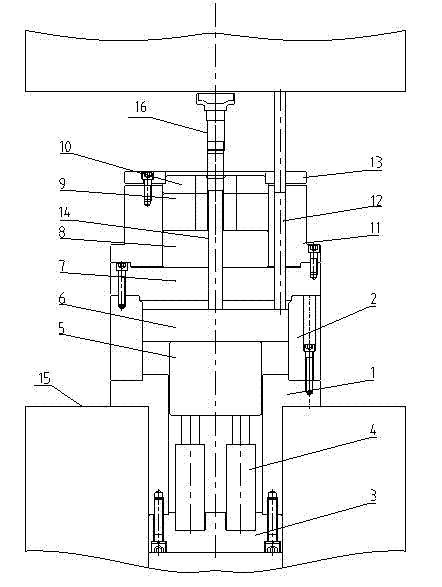

[0012] Such as figure 1 As shown, the symbols in the figure represent: first slider stroke cylinder 1, second slider stroke cylinder 2, nitrogen spring base 3, nitrogen spring 4, first slider 5, second slider 6, baffle plate 7. Block 8, mold 9, barrel mold 10, barrel mold jacket 11, pressure rod 12, gland 13, ejector rod 14 and press table 15. Wherein, the first slider stroke cylinder 1 is arranged on the press table 15, the lower end of the first slider stroke cylinder 1 is connected and fixed with the nitrogen spring base 3 by screws, and the nitrogen spring 4 is arranged on the nitrogen spring base 3 , the first slider 5 is set on the nitrogen gas spring 4, the second slider 6 is set on the first slider 5, the stroke cylinder 2 of the second slider is set on the outside of the second slider 6, and is fixed to the first slider by screws. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com