Novel outer wall beam for self-modeling self-insulation building

A self-insulation and building technology, applied in building construction, insulation, construction, etc., can solve the problems of long construction period, large manpower and material resources for installing and dismantling formwork, and separate construction of insulation materials, so as to reduce construction procedures and simplify structure. Construction, the effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

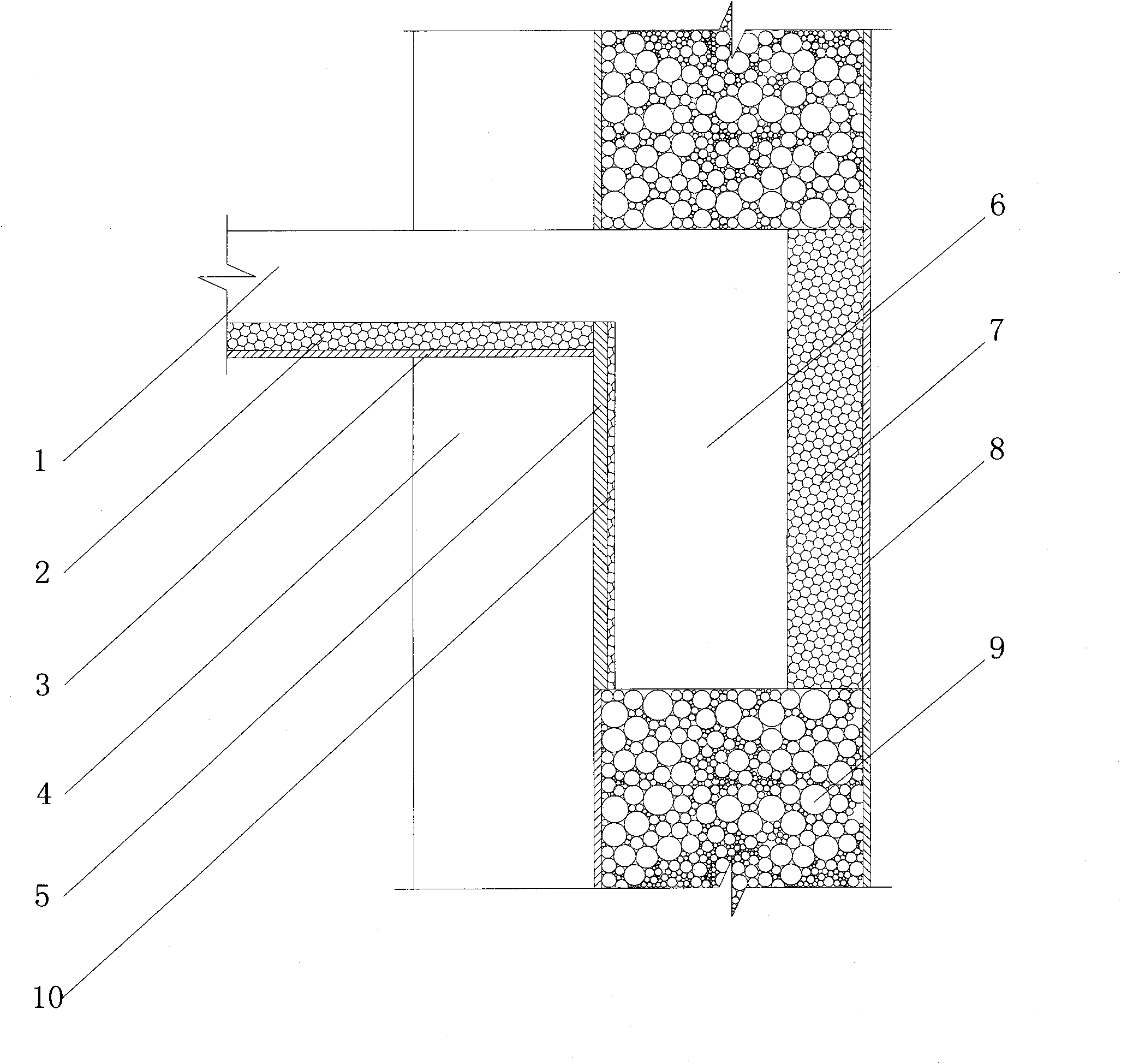

[0009] The accompanying drawing is a section diagram of the joints of the external wall beams. First, the filling wall 9 is constructed. The filling wall 9 has the functions of filling and heat preservation. The filling wall 9 can be realized by using a special self-insulating strip wall panel or other masonry materials. , the upper surface of the filling wall 9 is used as the base form and the beam formwork 5 and the formwork 8 to form the beam pouring groove 6, and the steel bar is put into and poured concrete to become the beam 6; the upper surface of the insulation material 2 of the floor formwork 3 and the upper end of the beam formwork 5 Flat, the upper surface of the hardened concrete slab is level with the height of the beam formwork 8 with the insulation material 7, and the reinforced concrete is put into the floor 1; the filling wall 9, the insulation material 7 and the insulation material 10 are formed External wall thermal insulation system; floor thermal insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com