Integrated anti-leakage type batching valve

An anti-drip, cylinder technology, applied in the field of tobacco machinery, can solve the problems of high requirements on the height of the upper equipment, affecting the cleanliness and hygiene of the workshop, and occupying a large space, and achieves the effects of fast batching speed, compact and reasonable structure, and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

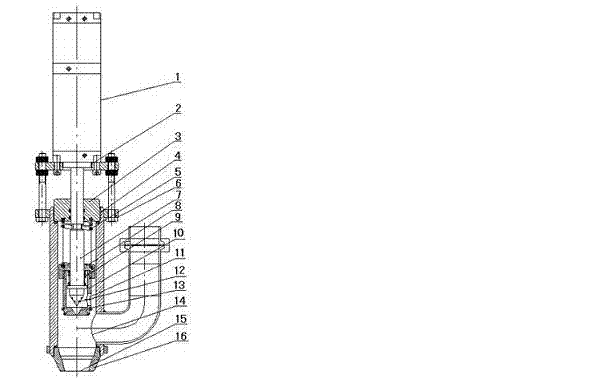

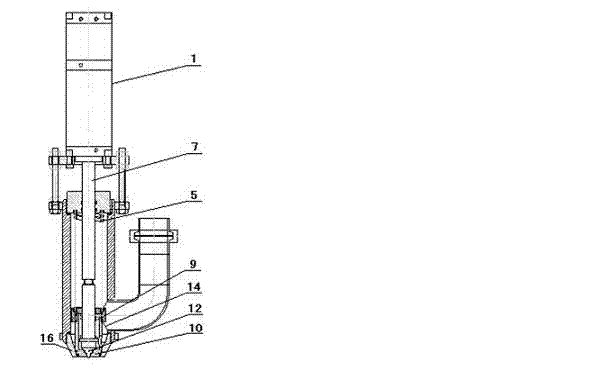

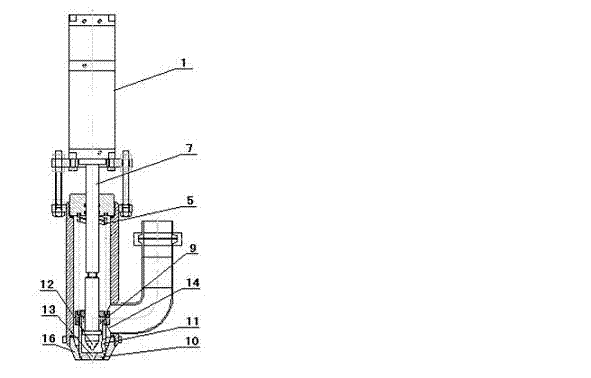

[0015] The accompanying drawings disclose a specific embodiment of the present invention in a non-limiting manner, which will be further described as follows in conjunction with the accompanying drawings.

[0016] See attached Figure 1~3 , the integrated anti-drip batching valve of the present invention is mainly composed of a two-position combination cylinder 1, a large flow cone valve, a small flow cone valve and two compression springs 5 and 9, the small The flow cone valve is arranged in the large flow cone valve, and the opening and closing of the small flow cone valve and the large flow cone valve are controlled by a two-position combined cylinder and a compression spring.

[0017] The above-mentioned large-flow cone valve includes a cylinder 4, an end cover 3, a cone 16, a valve stem 7, a spring plate 8 and a piston head 10. The cone 16 is fixed on the front end of the cylinder 4, and the front end of the cone 16 is provided with a There is a discharge port 15, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com