Composite permanent-magnet rotor for permanent-magnet motor and manufacturing method thereof

A technology of permanent magnet rotor and permanent magnet motor, which is applied in the direction of magnetic circuit rotating parts, manufacturing stator/rotor body, magnetic circuit shape/style/structure, etc. Magnetic, axial end magnetic flux leakage and other problems, to improve the ability of anti-electromagnetic interference and electromagnetic compatibility, low axial end magnetic flux leakage, and reduce the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

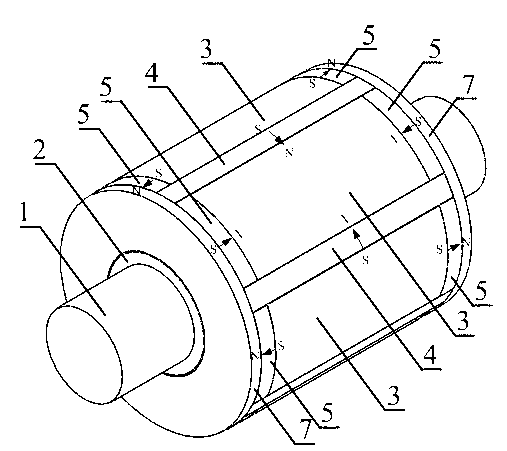

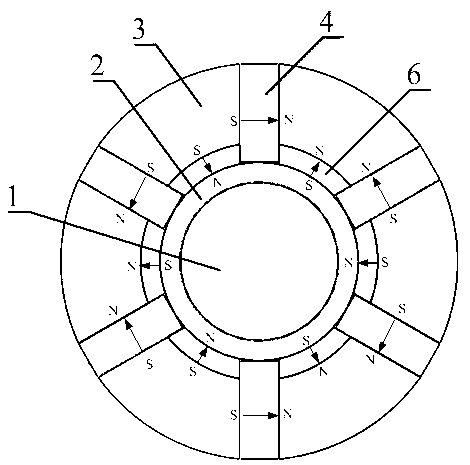

[0023] Embodiment 1 of the present invention: when making the rotor of permanent magnet motor, adopt the composite permanent magnet rotor manufacturing method of a kind of permanent magnet motor of the present invention to make, promptly when rotor iron core is installed on the rotor shaft, first in Put a magnetic sleeve made of magnetic material on the rotor shaft, then make the rotor core into a fan shape, and install and fix the fan-shaped rotor core evenly on the magnetic sleeve, and fix each one on the magnetic shaft Except for the arc-shaped upper end surface of the fan-shaped rotor core on the cover, the other five sides are all surrounded by permanent magnet blocks made of permanent magnetic materials, and make the joint between each permanent magnet block and the fan-shaped rotor core. The polarity of the magnetic poles is the same; when the fan-shaped rotor core is evenly distributed and fixed on the magnetic-conductive shaft sleeve, the fan-shaped rotor core and the ...

Embodiment 2

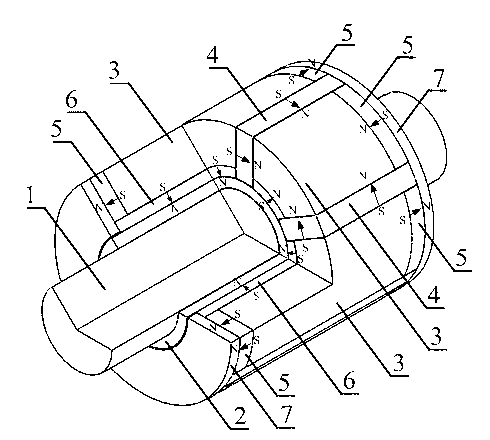

[0025] Embodiment 2: When making the compound permanent magnet rotor of a kind of permanent magnet motor of the present invention, can make according to the method for embodiment 1, when making, also can the axial end portion of the first permanent magnet block 4 top Hold the inner end surface of the end pressure plate 7, leave a gap between the radial inner end surface and the outer surface of the magnetic bushing 2, and the two sides of the second permanent magnet block 5 withstand the first permanent magnet block 4. There is a gap between the three permanent magnet blocks 6 sides (as Figure 6 shown); the rest of the production methods are the same as in Example 1.

Embodiment 3

[0026] Embodiment 3: when making the composite permanent magnet rotor of a kind of permanent magnet motor of the present invention, can make according to the method for embodiment 1, when making, also can connect the axial end of the first permanent magnet 4 with the annular There is a gap between the inner end faces of the end plate 7, a gap is left between the radial inner end face and the outer surface of the magnetically permeable bushing 2, and a gap is left between the sides of two adjacent second permanent magnet blocks 5, adjacent to each other. There is a gap between the two 3rd permanent magnet block 6 sides (as Figure 7 shown); the rest of the production methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com