Counterflow passing type ultrasonic processing equipment

An ultrasonic treatment and countercurrent technology, applied in the field of countercurrent through-type ultrasonic treatment equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

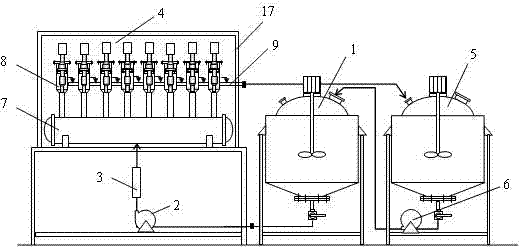

[0027] see figure 1 , figure 2 , a multi-probe countercurrent flow-through ultrasonic processing equipment, including a feed tank (1), a feed pump (2), a flow meter (3), an ultrasonic processing unit (4), a liquid storage tank (5) and a circulating pump ( 6), and install through the pipeline connection in the above order. The ultrasonic processing unit (4) of the device includes a buffer (7), 8 ultrasonic processors (8), a discharge liquid collection pipe (9) and a soundproof cover (17).

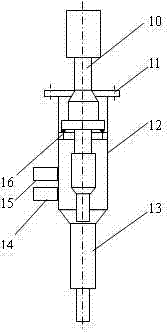

[0028] The ultrasonic processor (8) described therein includes a concentrated-energy ultrasonic transducer (10), a cup barrel (12) for placing the concentrated-energy ultrasonic transducer (10), a cup barrel cover (11), and a (12) The processing chamber (13) at the lower end, the overflow port (14) located on the side of the cup barrel (12) higher than the bottom end of the concentrated ultrasonic transducer (10), and the upper end of the overflow port (14) to prevent feeding If the spe...

Embodiment 2

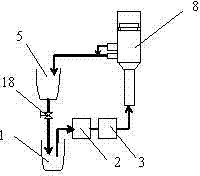

[0033] see figure 2 , image 3 , a single-probe countercurrent flow-through ultrasonic processing equipment, which includes: a feed tank (1), a feed pump (2), a flow meter (3), an ultrasonic processor (8), a liquid storage tank (5) and a valve (18), and connect and install through pipelines in the above sequence.

[0034] The ultrasonic processor (8) described therein includes a concentrated-energy ultrasonic transducer (10), a cup barrel (12) for placing the concentrated-energy ultrasonic transducer (10), a cup barrel cover (11), and a (12) The processing chamber (13) at the lower end, the overflow port (14) located on the side of the cup barrel (12) higher than the bottom end of the concentrated ultrasonic transducer (10), and the upper end of the overflow port (14) to prevent feeding If the speed is too fast, the liquid level in the cup barrel (12) is too high, the spare overflow port (15), and the stop ring (16) located on the upper part of the cup barrel (12) for fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com