Purifier with cleaning function

A purifier and functional technology, used in electrode cleaning, electrostatic separation, etc., can solve the problems of troublesome disassembly and assembly, delaying purification work, unrealistic operation, etc., and achieves short cleaning time, simple overall structure and ideal cleaning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

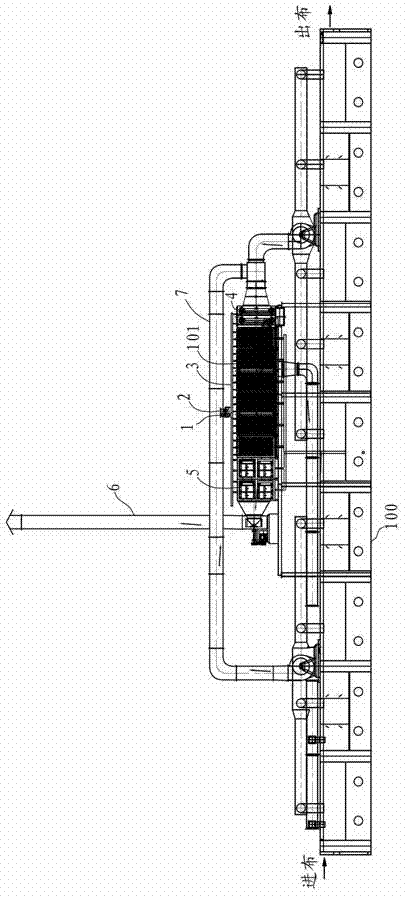

[0021] Such as figure 1 As shown, the purifier 5 in this embodiment is used as a deep secondary purification and is applied to the oven 100 of the setting machine. The hot gas in the waste gas pipe 7 passes through the primary purifier 4, the heat exchanger 101, and the purifier 5 successively, and finally from the The discharge pipe 6 is discharged, so that the exhaust gas produced in the cloth setting process is discharged after heat exchange, most of the heat is recycled, and the energy consumption is reduced.

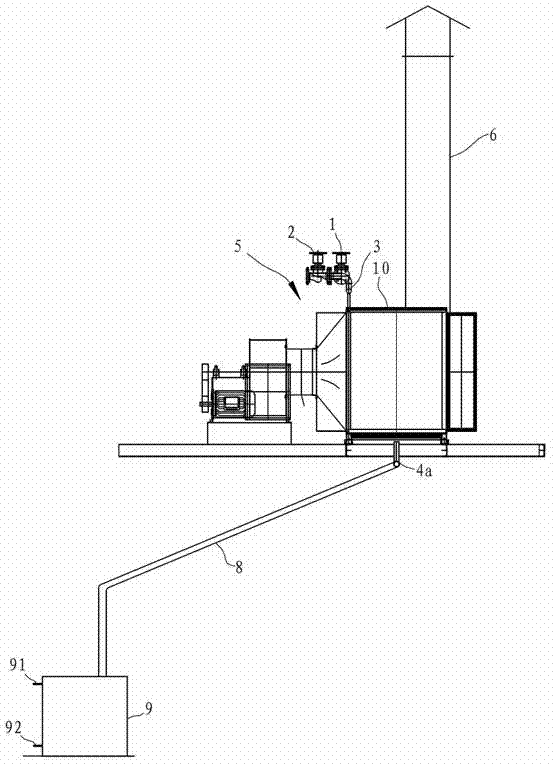

[0022] Such as figure 2 As shown, the purifier 5 includes a purifier body 10 , a spray pipe 3 and an oil-water separation device 9 .

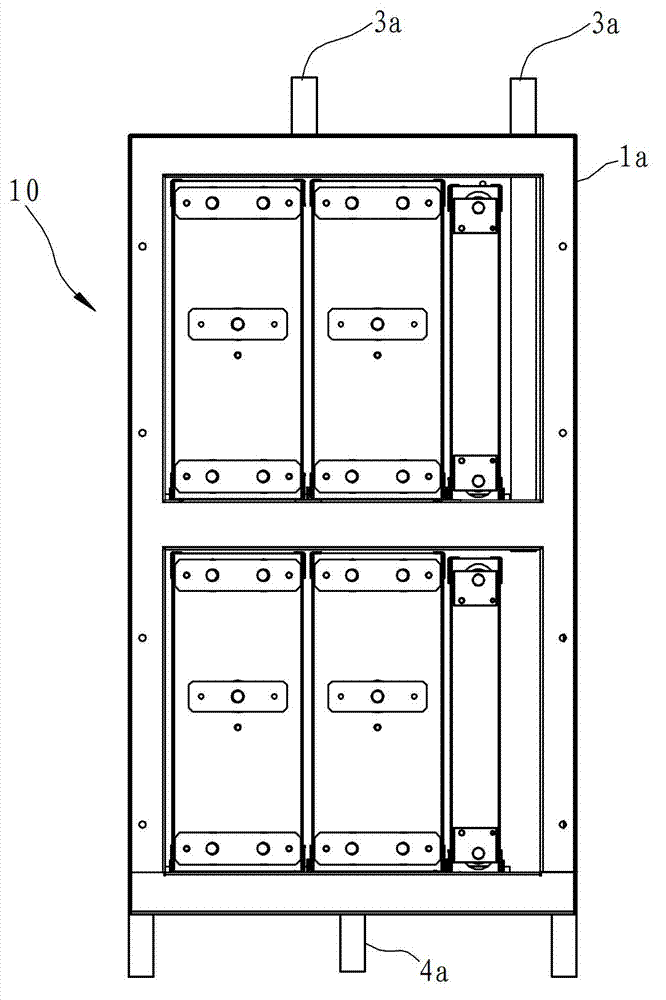

[0023] Such as image 3 , Figure 4 and Figure 5 As shown, the purifier body 10 in this embodiment includes a housing 1a and an electrode plate 2a disposed in the housing 1a. The bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com