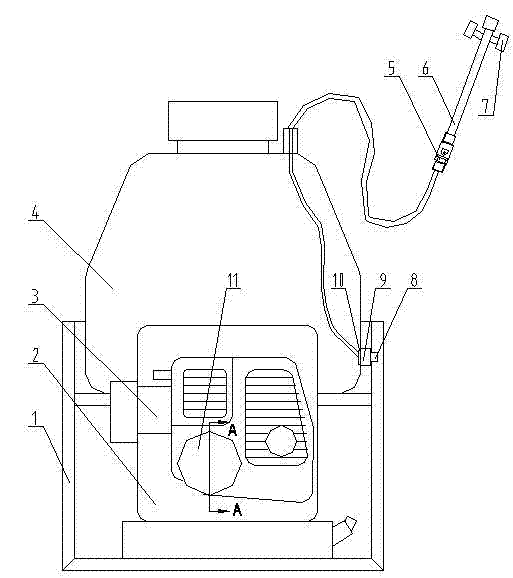

Low-pressure airflow atomizing sprayer

A fog machine and airflow technology, which is applied in the direction of exhaust devices, mechanical equipment, engine components, etc., can solve problems such as the inability to control the amount of pesticide liquid in and out, easy wear of clutches and clutch plates, and no special switch for spray rods, etc., to achieve Avoid the loss of liquid medicine, low cost, easy to manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An expressway management office in Nanning, Guangxi, in January 2012, used this low-pressure airflow mist machine to spray pesticides on the flower belt hedges on both sides and in the middle of the expressway for insecticide. After using it for more than five months, the flower belt hedges The spraying speed has increased by more than 10 times than before, and the sprayed pesticides are uniform, which has been praised by the Municipal Civilization Office.

Embodiment 2

[0034] Lu Mou, Wuming County, Nanning City, Guangxi, in February 2012, used this low-pressure airflow mist machine to spray pesticides on the 100 mu of Chinese fir forest contracted by him to prevent and control diseases, insects, and weeds. After three months Trial, the spraying effect is good, the spraying speed is greatly improved, and the pesticides are saved by more than 20 times compared with the original sprayers on the market.

Embodiment 3

[0036] Wei Mou, Xiangzhou County, Laibin City, Guangxi, in February 2012, used this low-pressure airflow mist machine to spray pesticides on 10 acres of pomelo trees and crops on his own mountain to kill insects. After three months of trial, the spraying effect Well, the fruit trees and crops are doing well after spraying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com