Rubber product flash press-cutting tool

A technology for rubber products and burrs, applied in the field of burr pressing and cutting tools, can solve the problems of burr residue, unsatisfactory treatment effect, poor burr treatment effect, etc., achieving a simple and effective operation process, reducing quality management costs, The effect of low cost of pressing and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

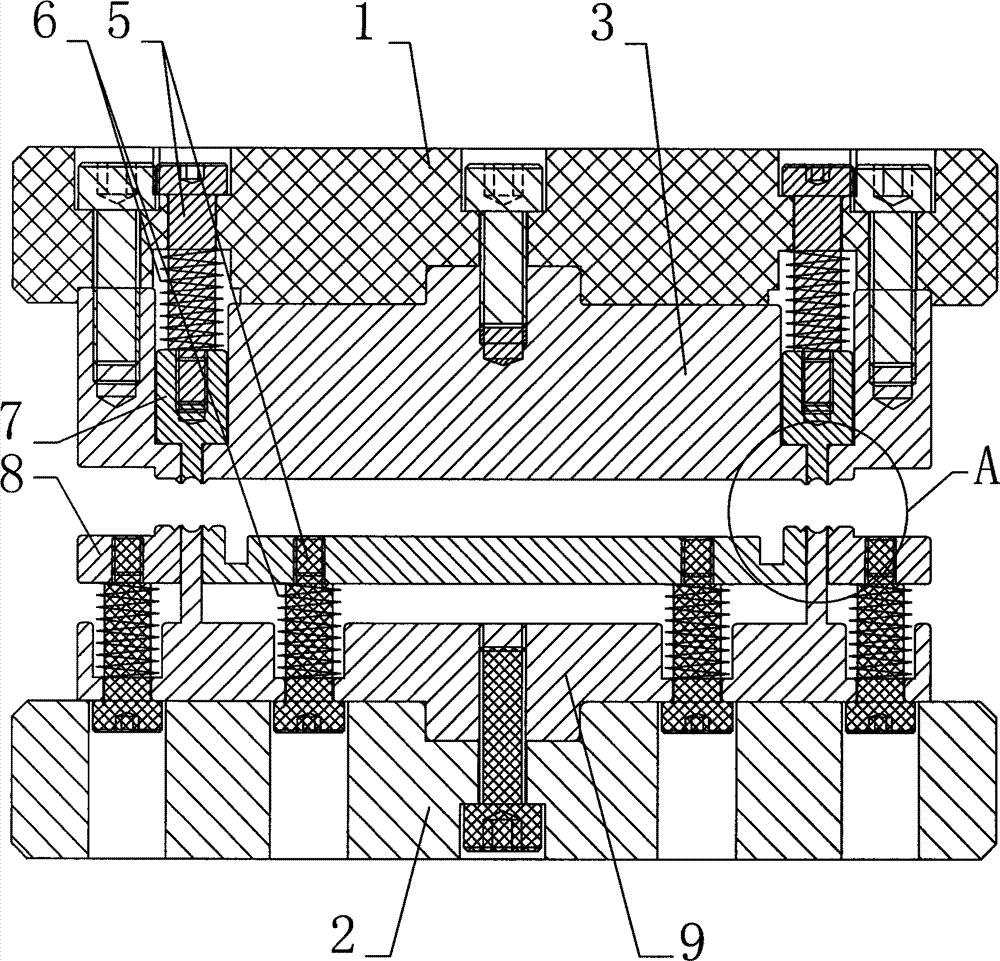

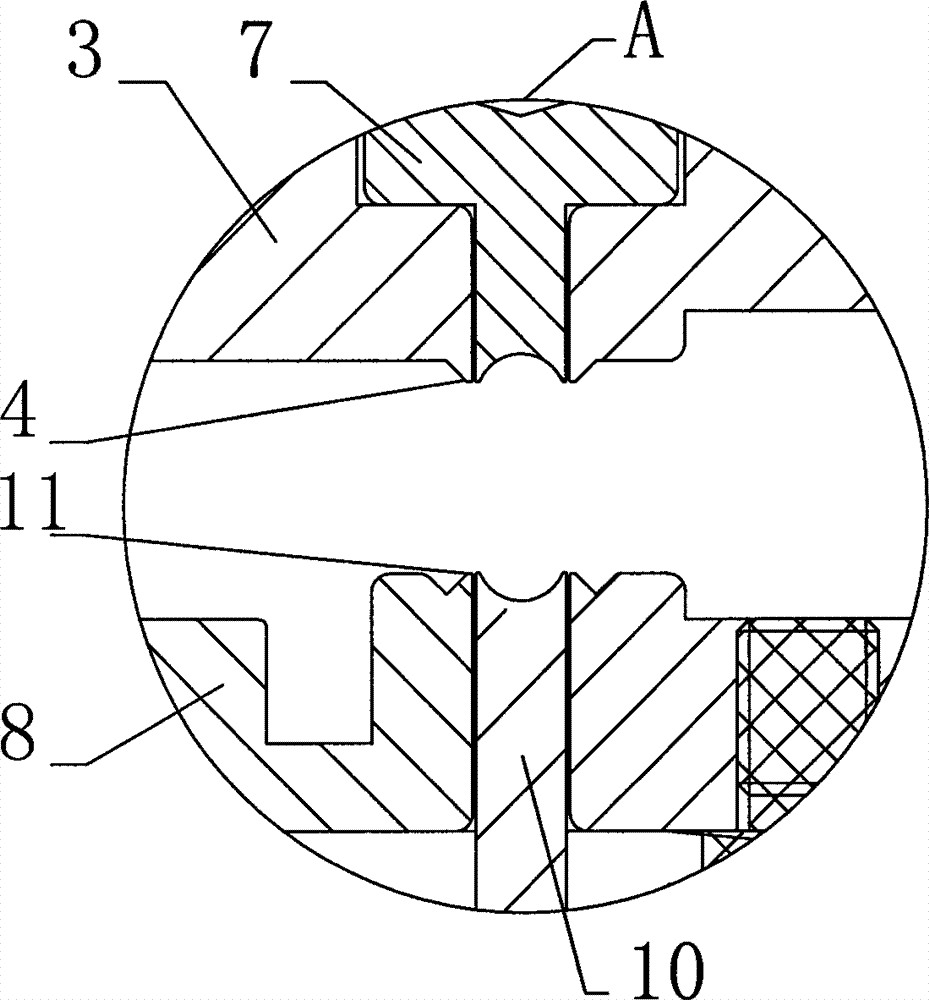

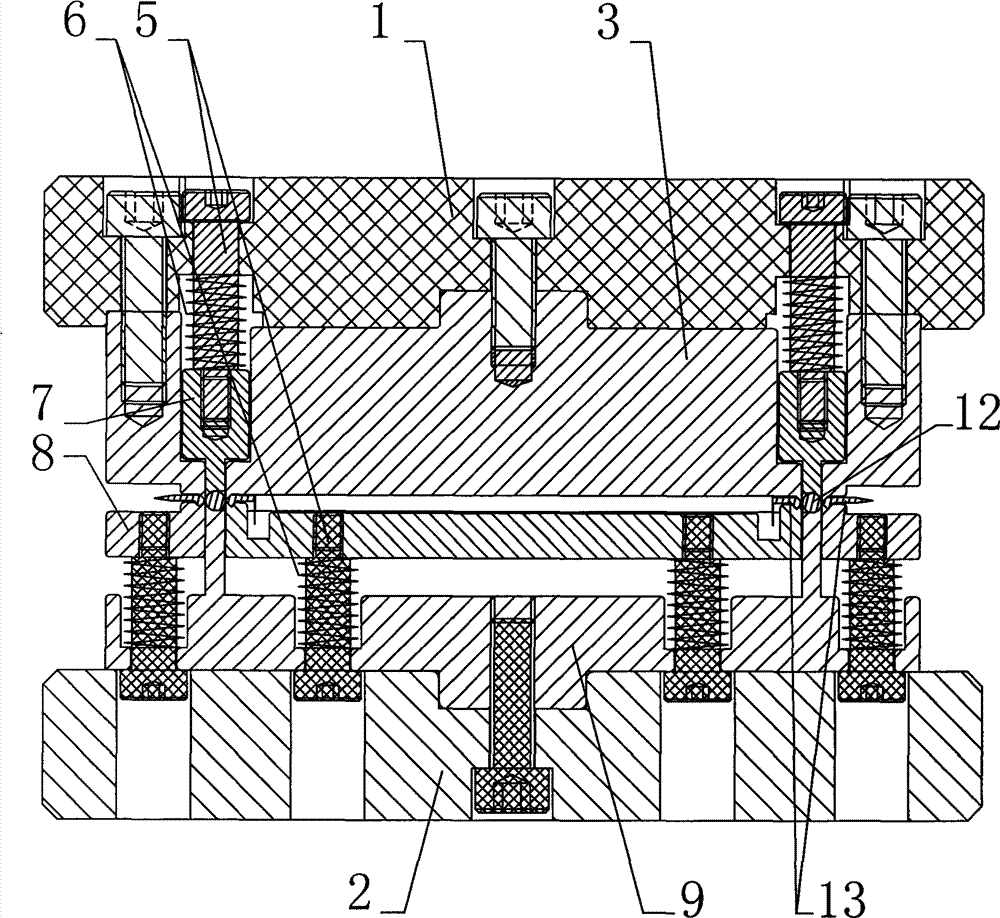

[0020] like figure 1 , 2 As shown, the flash cutting tool for rubber products includes an upper substrate 1 and a lower substrate 2 . An upper clamping assembly and a pressing and cutting plate 3 are arranged on the upper base plate 1. The whole pressing and cutting plate 3 is a flat plate structure, and is fixedly connected with the upper base plate 1 by screws. A T-shaped through hole is provided inside the upper substrate 1 , and the T-shaped through hole is composed of two sections of through holes with different diameters. like figure 2 As shown, the pressing plate 3 is provided with protrusions I4 at the end of the T-shaped through hole with a smaller diameter, and the protrusions I4 are distributed on both sides of the T-shaped through-hole and are symmetrical with respect to the center line of the T-shaped through-hole. The cross section of the protrusion I4 is triangular, and the surface facing the T-shaped through hole is flush with the inner surface of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com