Pressing mechanism of oil press

An oil press and press cavity technology, applied in presses, manufacturing tools, etc., can solve the problems of large volume and large pressing mechanism, and achieve the effects of high pressing efficiency, preventing jamming, and increasing radial friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

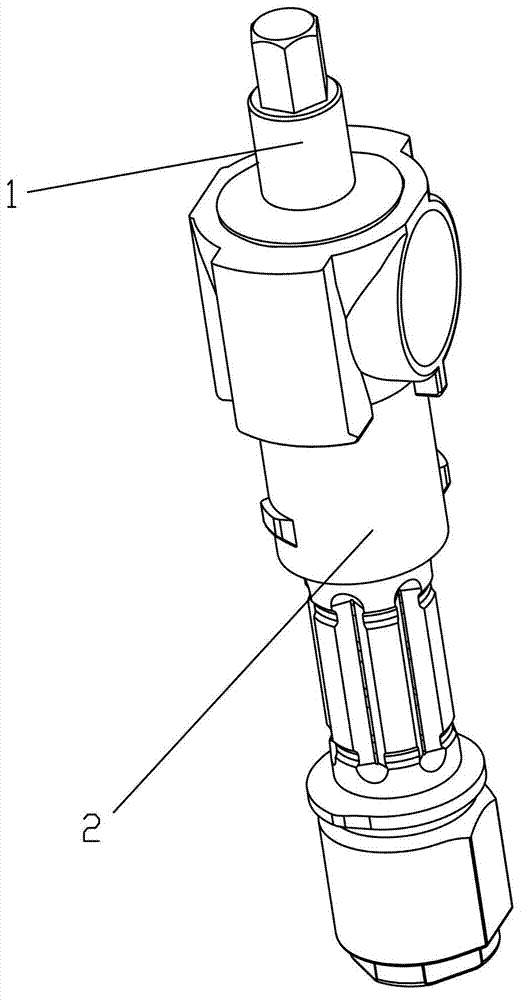

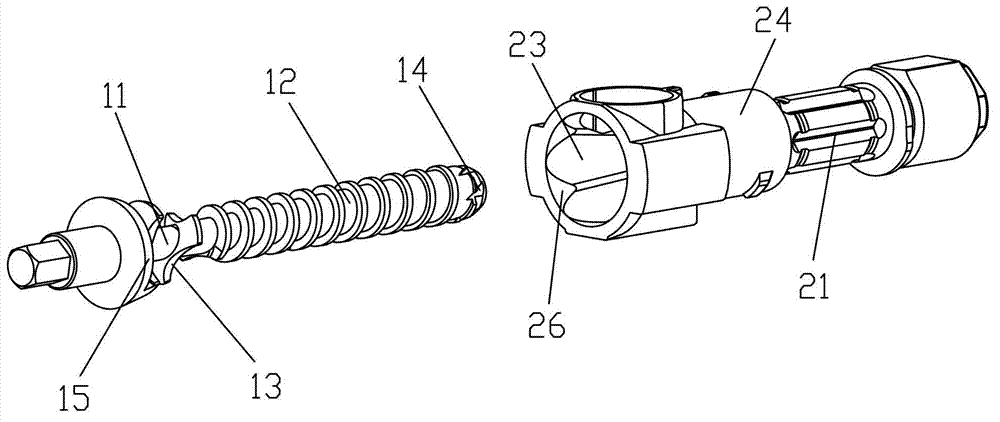

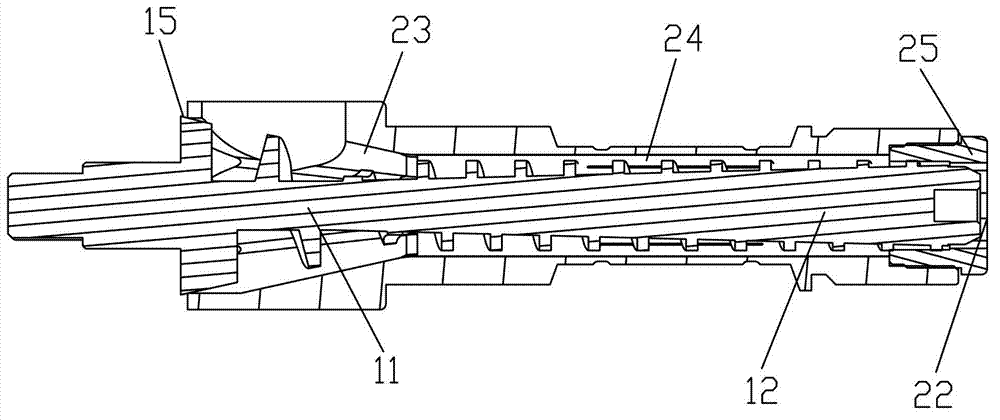

[0017] refer to figure 1 , figure 2 , image 3 , a pressing mechanism of an oil press, comprising a pressing screw 1 and a pressing barrel 2 matched therewith, the side wall of the pressing barrel 2 is provided with an oil outlet groove 21, and the tail end of the pressing barrel 2 is provided with a slag outlet 22, the The squeeze cylinder 2 is divided into a conveying chamber 23 in the front section and a squeeze chamber 24 in the rear section; the diameter of the squeeze chamber 24 is smaller than the diameter of the conveying chamber 23; the squeeze screw 1 is divided into a conveying section 11 in the front section - corresponding to the conveying Cavity 23, the squeezing section 12 of the rear section—corresponding to the squeezing chamber 24 of the squeezing cylinder 2, the outer diameter of the thread of the squeezing screw 1 gradually decreases from the front to the rear of the conveying section 11, and remains constant after entering the squeezing section 12. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com