Washing assembly of ink-jet printer

An inkjet printer and component technology, applied in the field of cleaning components of inkjet printers, can solve the problems of processing difficulty and high processing cost, and achieve the effects of reasonable functional layout, wide compatibility and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

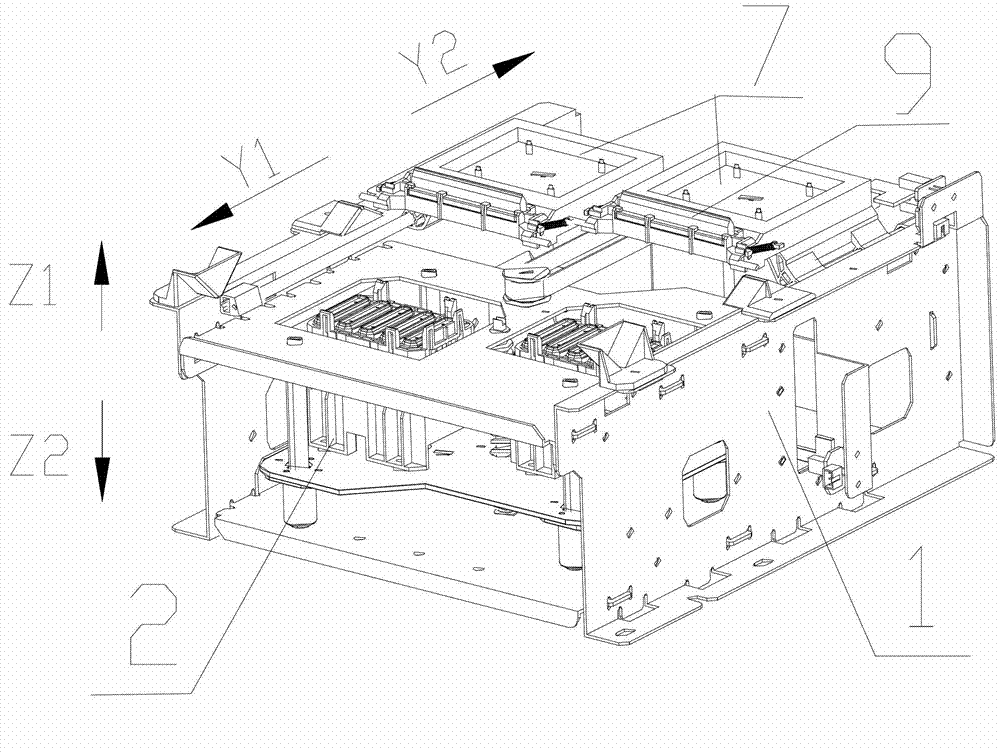

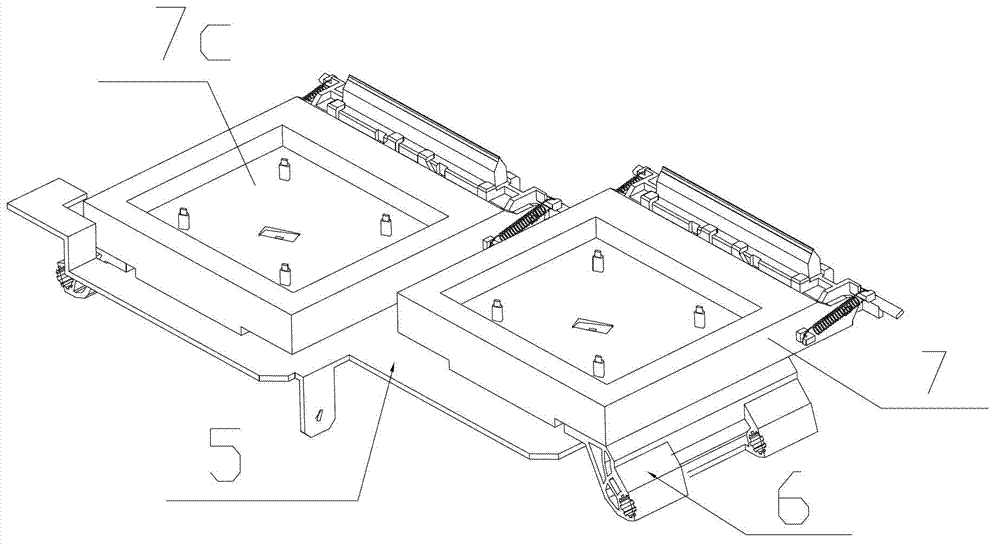

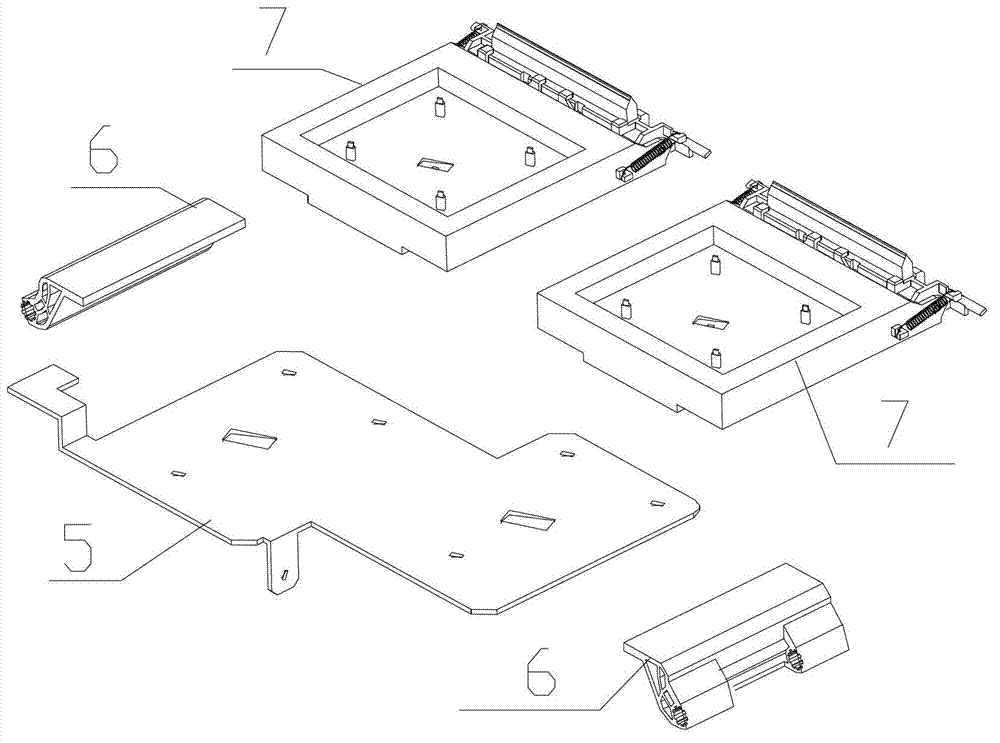

[0033] combined with Figure 1-13 , a cleaning assembly of an inkjet printer, comprising a support 1, a micro-spray pad 7, an ink scraping assembly and an ink stack 2, the micro-spray pad 7 is provided with a micro-spray groove 7c, and the micro-spray pad 7 is fixed on a slide set of 6 on the support plate 5 (eg Figure 2-3 As shown), the sliding sleeve 6 is installed on the two side plates 13, 14 of the bracket 1, the micro spray groove 7 can slide horizontally along the bracket, the scraper assembly includes a scraper blade 9 made of rubber, a scraper blade support body 8 and spring 10, the squeegee blade 9 is installed on the squeegee blade support body 8 through the card slot 8d embedded in the squeegee blade support body 8, and the pins 8a on both sides of the squeegee blade support body 8 are connected with the micro-spray pad 7 respectively. The pin holes 7a on both sides are rotatably connected, buckles 8b are provided on both sides of the squeegee support body 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com