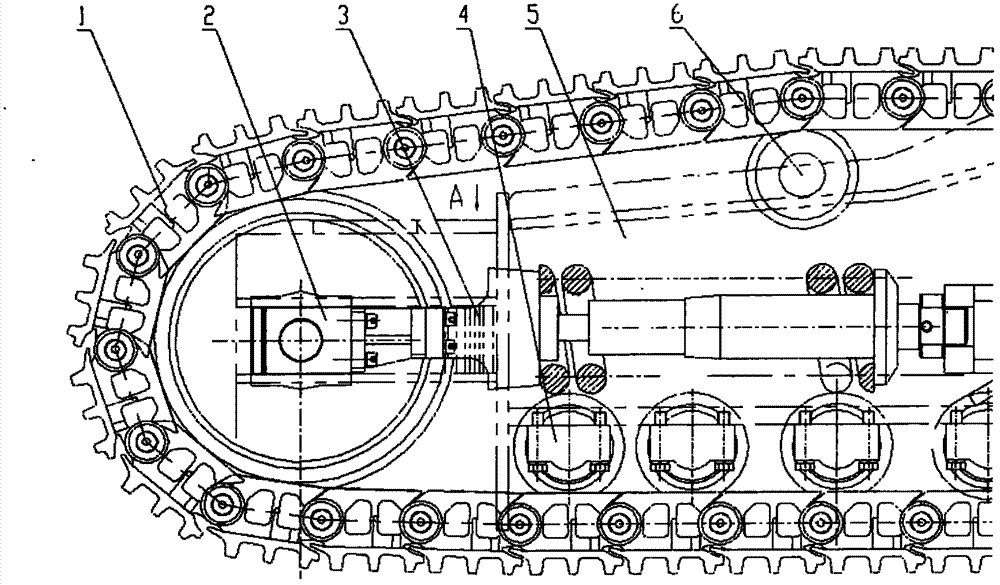

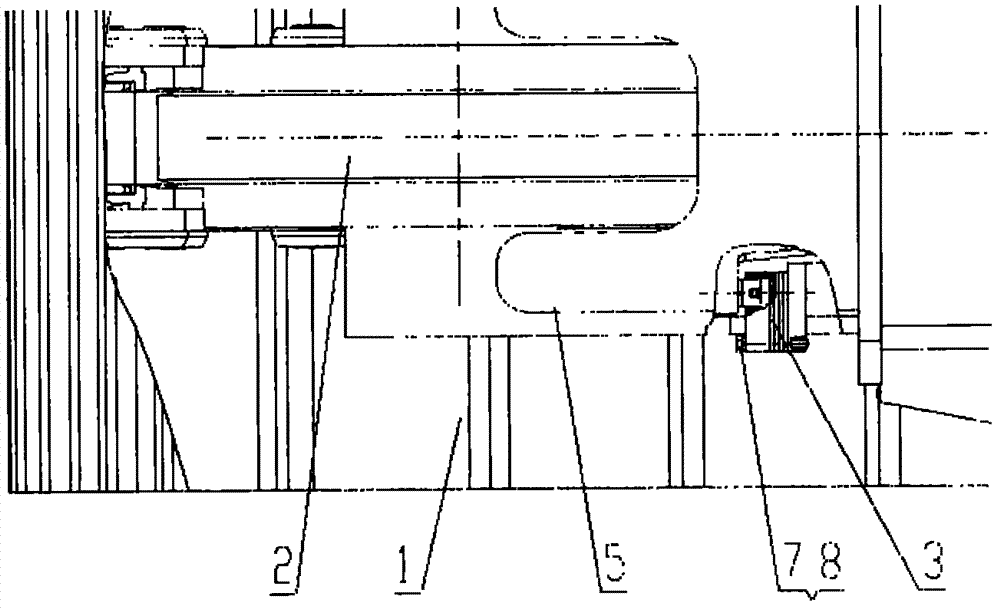

Combined tensioning mechanism for caterpillar band

A combined tensioning and crawler technology, applied to tracked vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of increased impact force and unsatisfactory compression spring adaptability, and achieve reliable performance, simple structure and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Install the tensioning device (2) into the inside of the longitudinal beam (5) from one end as required, and ensure that the slide rails on both sides of the guide wheel correctly enter the groove of the longitudinal beam, and at the same time make the exposed end of the cylinder piston rod In the round hole of the beam vertical plate, the oil injection valve points to the outside; then install the track roller (4) and the supporting sprocket (5) on the upper and lower planes of the longitudinal beam (5); flatten the track assembly (1) On the ground, place the longitudinal beam parts that have just been assembled together on the assembly, and then complete the connection of the head and tail pins of the track. Then add grease to the oil cylinder of the tensioning device. With the continuous increase of the total length of the part, a certain gap will be formed between the lugs on both sides of the support and the bracket welded at the rectangular hole of the longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com