Plastic bottle gas-wash control device in plastic bottle large-infusion washing-filling-sealing machine

A plastic bottle washing, filling and sealing technology, which is applied in the program control of the sequence/logic controller, electrical program control, bottling machine, etc., can solve the problems of poor quality of plastic bottle air washing and scattered blowing volume, and achieve Concentrated blowing volume and good blowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

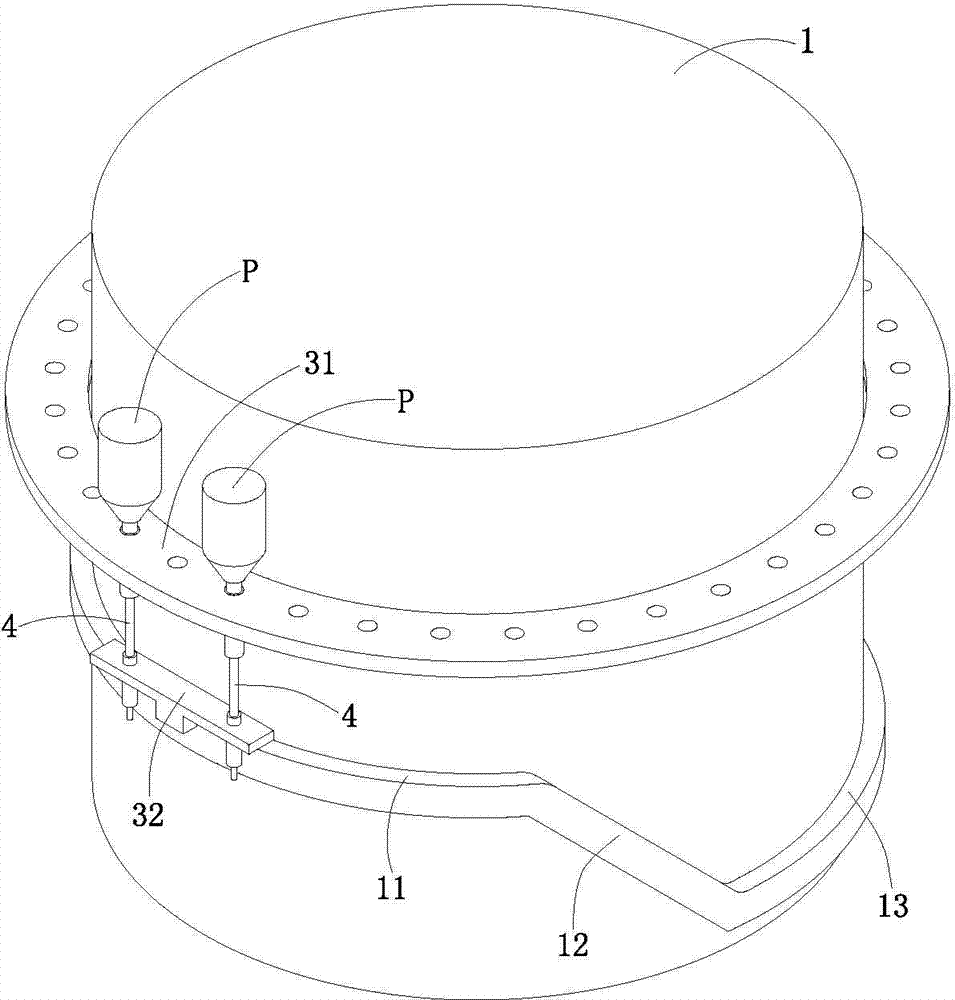

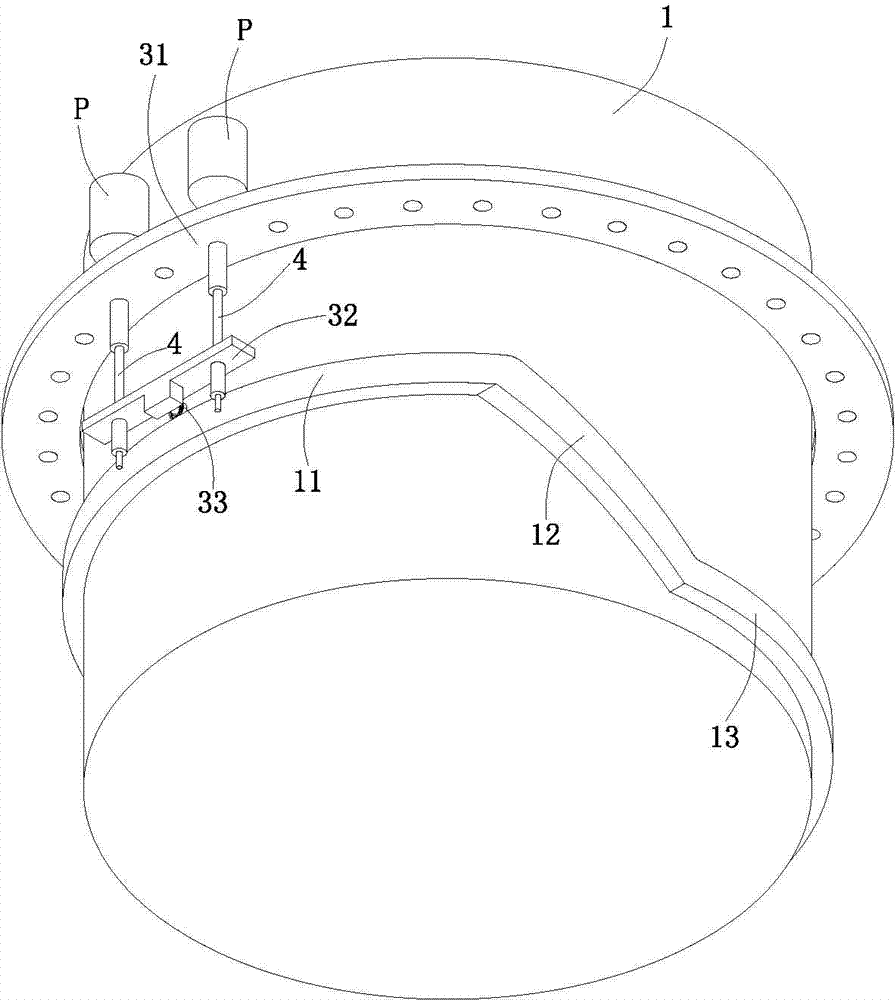

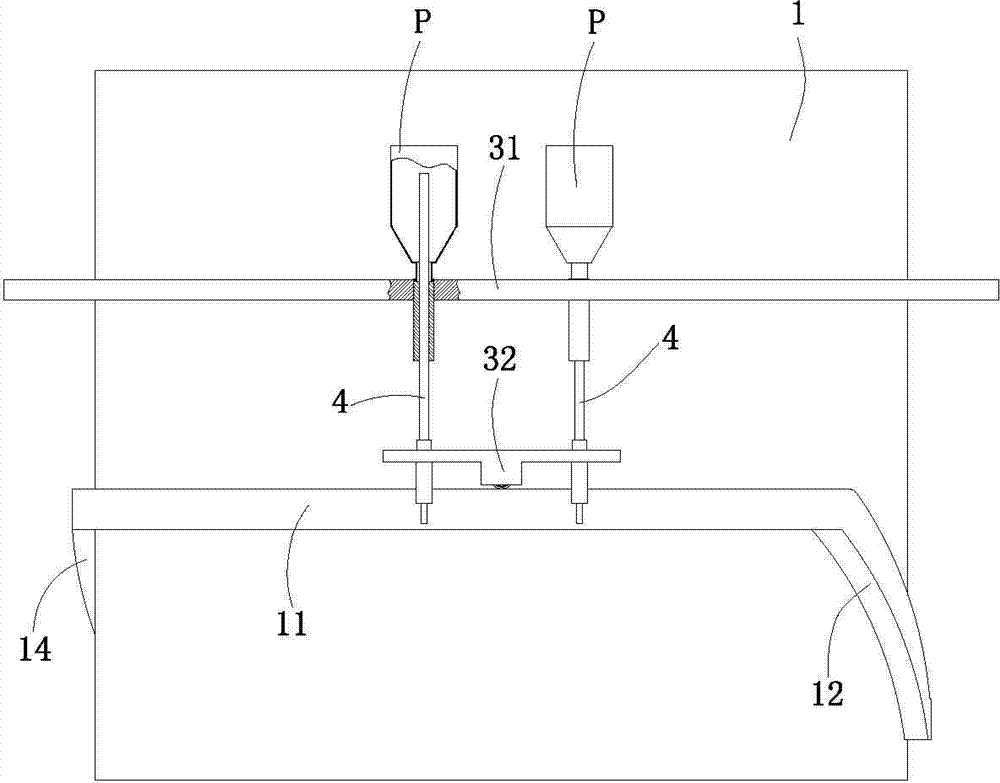

[0031] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] see figure 1 — Figure 7 :

[0033] The device includes an inner rotating cylinder 2, an outer fixing cylinder 1, a cam 15, nine proximity switches, nine relays, nine solenoid valves, an actuator for positioning and rotating the plastic bottle P in the circumferential direction and moving the blowing nozzle 4 up and down .

[0034] The nine proximity switches are: proximity switch SQ1, proximity switch SQ2, proximity switch SQ3, proximity switch SQ4, proximity switch SQ5, proximity switch SQ6, proximity switch SQ7, proximity switch SQ8, proximity switch SQ9.

[0035] The nine relays are: Relay JA 1 , Relay JA 2 , Relay JA 3 , Relay JA 4 , Relay JA 5 , Relay JA 6 , Relay JA 7 , Relay JA 8 , Relay JA 9 .

[0036] The nine solenoid valves are: solenoid valve YV81, solenoid valve YV82, solenoid valve YV83, solenoid valve YV84, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com