Air catalytic oxidation treatment benzyl cyanide waste water method

A catalytic oxidation and air oxidation technology, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of complicated treatment procedures, unsafe, high treatment costs, etc., and achieve technological process Simple, flexible operation, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

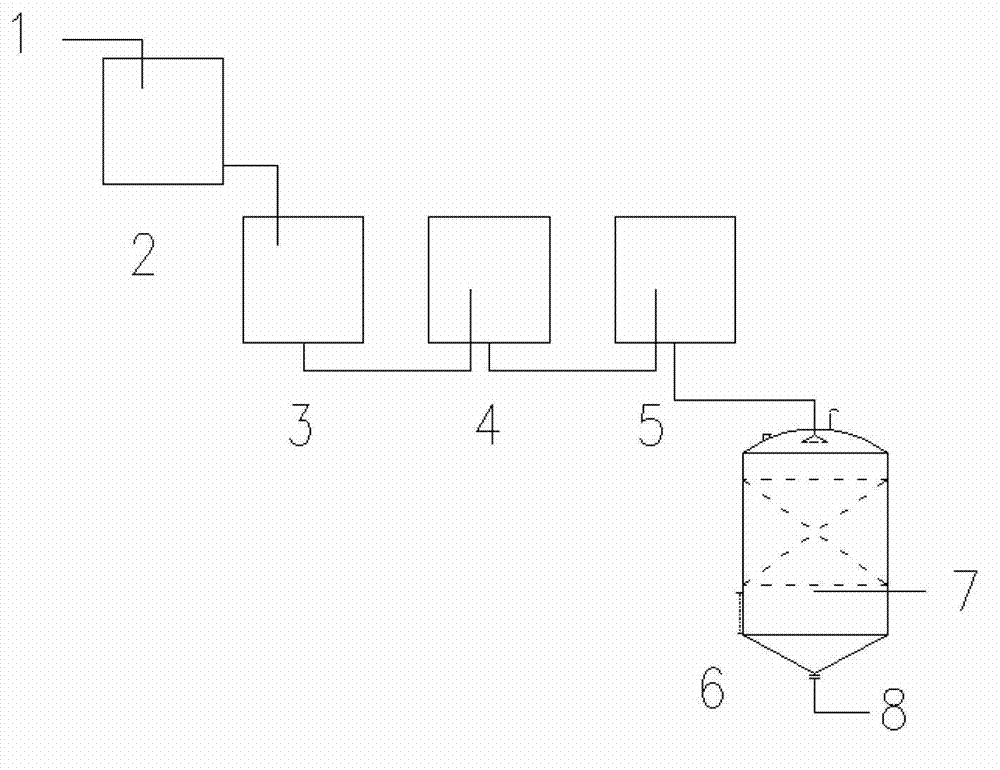

[0017] A method for air catalytic oxidation treatment of phenylacetonitrile wastewater, using activated carbon as a co-catalyst, soaking the activated carbon with copper sulfate solution as a main catalyst, making a composite catalyst, and loading it into an air oxidation tower 6; the pretreated phenylacetonitrile wastewater is discharged from the air oxidation tower The upper part of 6 enters the air oxidation tower 6, and the air enters from the lower part of the air oxidation tower 6, the waste water is in countercurrent contact with the air, and the treated water flows out from the lower part of the tower; the specific operation steps are as follows:

[0018] (1) Activation of activated carbon, preparing a copper sulfate solution with a mass fraction of 15%, pouring it into the air oxidation tower 6 to spray impregnated activated carbon, passing air through the air inlet 7 to dry the water for later use;

[0019] (2) Wastewater pretreatment, inject phenylacetonitrile wastew...

Embodiment 2

[0024] A method for air catalytic oxidation treatment of phenylacetonitrile wastewater, using activated carbon as a co-catalyst, soaking the activated carbon with copper sulfate solution as a main catalyst, making a composite catalyst, and loading it into an air oxidation tower 6; the pretreated phenylacetonitrile wastewater is discharged from the air oxidation tower The upper part of 6 enters the air oxidation tower 6, and the air enters from the lower part of the air oxidation tower 6, the waste water is in countercurrent contact with the air, and the treated water flows out from the lower part of the tower; the specific operation steps are as follows:

[0025] (1) Activation of activated carbon, preparing a copper sulfate solution with a mass fraction of 15%, pouring it into the air oxidation tower 6 to spray impregnated activated carbon, passing air through the air inlet 7 to dry the water for later use;

[0026] (2) Wastewater pretreatment, inject phenylacetonitrile wastew...

Embodiment 3

[0031] A method for air catalytic oxidation treatment of phenylacetonitrile wastewater, using activated carbon as a co-catalyst, soaking the activated carbon with copper sulfate solution as a main catalyst, making a composite catalyst, and loading it into an air oxidation tower 6; the pretreated phenylacetonitrile wastewater is discharged from the air oxidation tower The upper part of 6 enters the air oxidation tower 6, and the air enters from the lower part of the air oxidation tower 6, the waste water is in countercurrent contact with the air, and the treated water flows out from the lower part of the tower; the specific operation steps are as follows:

[0032] (1) Activation of activated carbon, preparing a copper sulfate solution with a mass fraction of 15%, pouring it into the air oxidation tower 6 to spray impregnated activated carbon, passing air through the air inlet 7 to dry the water for later use;

[0033] (2) Wastewater pretreatment, inject phenylacetonitrile wastew...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap