Preparation method and system of toner pre-dispersing material

A pre-dispersion and toner technology, applied in the direction of organic dyes, can solve the problems of light fastness, heat resistance, and poor weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

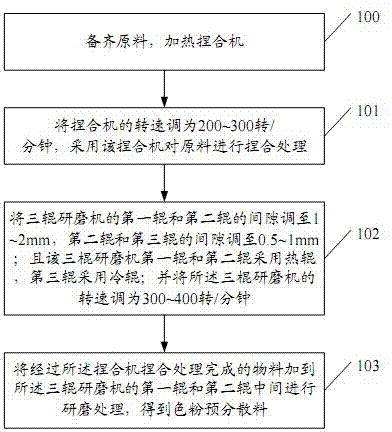

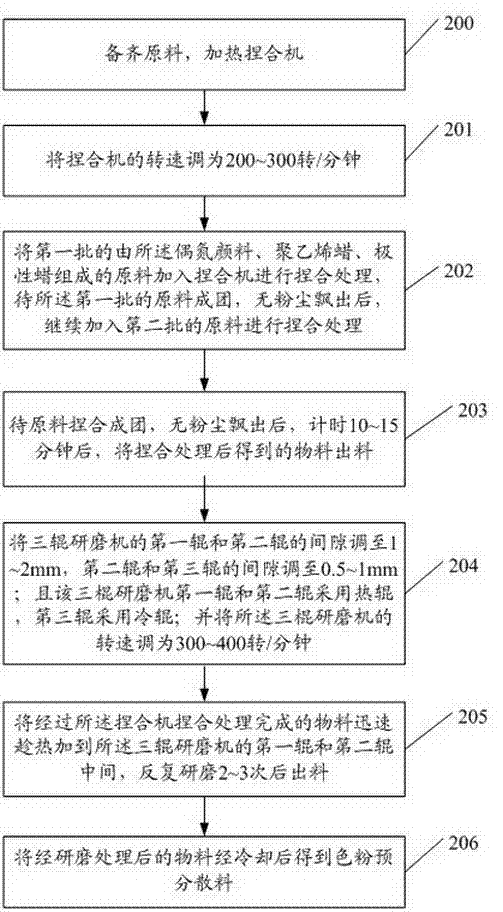

Method used

Image

Examples

preparation example Construction

[0038] In order to solve the technical problems in the prior art, the invention provides a method and system for preparing toner predispersed material.

[0039] First of all, it should be noted that the kneader mentioned in the present invention is a machine for uniform mixing of semi-dry or viscous materials composed of a pair of intermeshing and rotating Z-shaped or S-shaped blades. the

[0040] The kneader is mainly composed of five parts: the kneading part, the base part, the hydraulic system, the transmission system and the electric control system. The hydraulic system uses a hydraulic station to control the large oil cylinder to complete the opening and closing function, and the hydraulic system uses a hydraulic station to control the oil cylinder to complete functions such as turning over the cylinder and opening the cover. The detailed parameters can be set and requested by the user arbitrarily. Easy to operate and reliable. The transmission system is composed of ele...

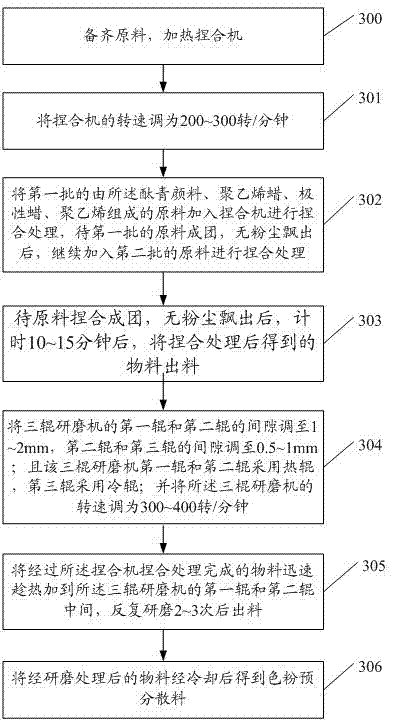

Embodiment 1

[0061] The method of the first embodiment specifically includes:

[0062] Step 200, prepare the raw materials and heat the kneader;

[0063] After accurately weighing and marking all kinds of raw materials, put them neatly for use, and check whether the kneader needs to be cleaned; confirm that the kneader is clean, and knead in strict accordance with the process requirements after the heating is completed.

[0064] Step 201, adjusting the rotational speed of the kneader to 200~300 rpm;

[0065] Specifically, it can be 200 rpm, 250 rpm, 300 rpm, etc. The speed of the kneader should not be too fast, so as not to affect the kneading effect due to idling.

[0066] Step 202, adding the first batch of raw materials consisting of the azo pigments, polyethylene wax, and polar wax to a kneader for kneading treatment, and after the first batch of raw materials are kneaded into agglomerates and no dust floats out , continue to add the second batch of raw materials for kneading treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com