Military ammunition can material and preparation method thereof

A bullet box and military technology, which is applied in the field of military bullet box materials and its preparation, can solve the problems of poor radiation protection performance, heavy steel packaging weight, and long processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

[0054] Example 1.1: Product No. LFT-1

[0055] The LFT-1 of the present invention is prepared from the following raw materials by weight percentage: homopolymer PP, produced by Sinopec Luoyang Branch, brand MN100, with an addition of 40wt% (wt% is weight percentage, the same below); glass fiber is Shandong Produced by Taishan, the preferred brand is T635B, and the addition amount is 50wt%. The compatibilizer is produced by Xiamen Keaisi Company, the preferred brand is B1, and the addition amount is 10wt%.

[0056] The performance of LFT-1 produced by the above formula is shown in attached table 1:

[0057] Attached Table 1 LFT-1 Performance Test Statistical Results

[0058] project testing method LFT-1 Melt index, g / 10min(200℃, 5Kg) GB3682 4.6 tensile yield strength, MPa

Embodiment 12

[0059] Example 1.2: Product No. LFT-2

[0060] The LFT-2 of the present invention is prepared from the following raw materials by weight percentage: Homopolymer PP produced by Sinopec Luoyang Branch, brand MN100, with an added amount of 34wt%; glass fiber is produced in Taishan, Shandong, with a preferred brand of T635B, added with an added amount of 55wt% , the compatibilizer is produced by Xiamen Keaisi Company, the preferred brand B1, and the addition amount is 11wt%.

[0061] The performance of LFT-2 produced by the above formula is shown in attached table 2:

[0062] Attached Table 2 LFT-2 Performance Test Statistical Results

[0063] project testing method LFT-2 Melt index, g / 10min(200℃, 5Kg) GB3682 4.1 tensile yield strength, MPa

GB / T1040 108.3 Elongation at break% GB / T1040 5.0 Bending strength, MPa

GB / T9341 156.2 flexural modulus, MPa

GB / T9341 8996.4 Normal temperature notched impact strength, KJ / ...

Embodiment 21

[0069] Example 2.1: Product No. GF-1

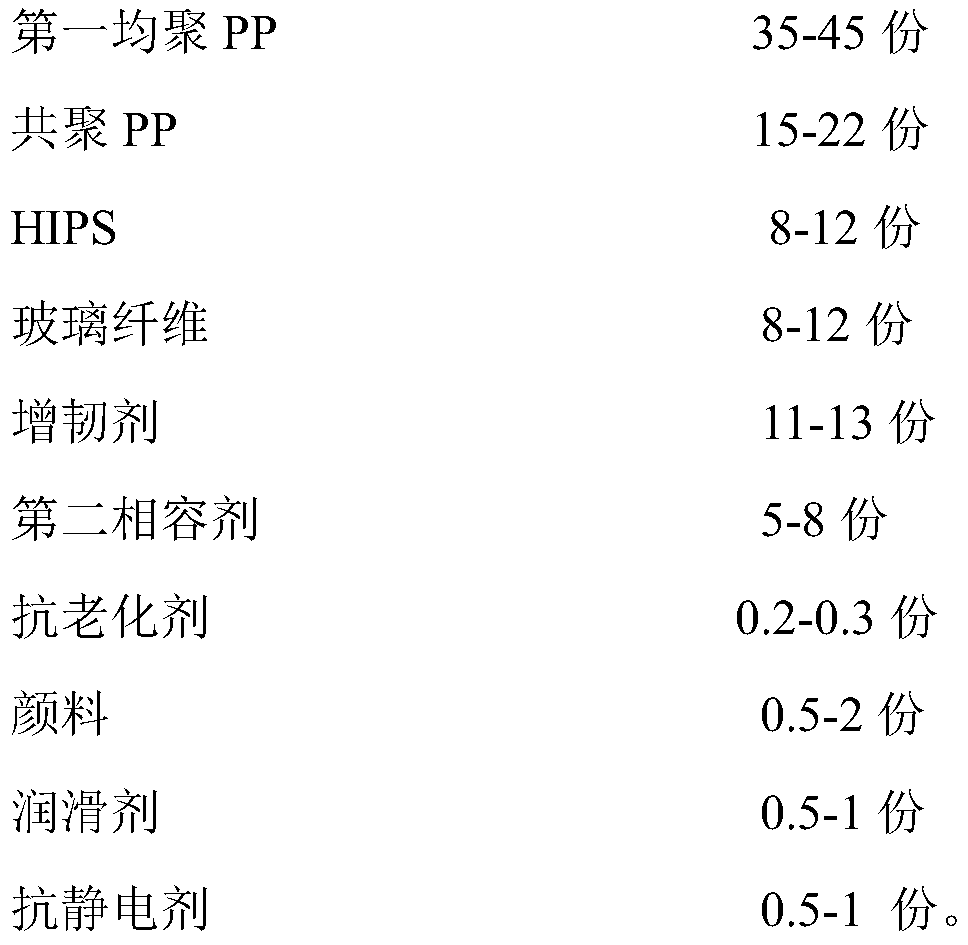

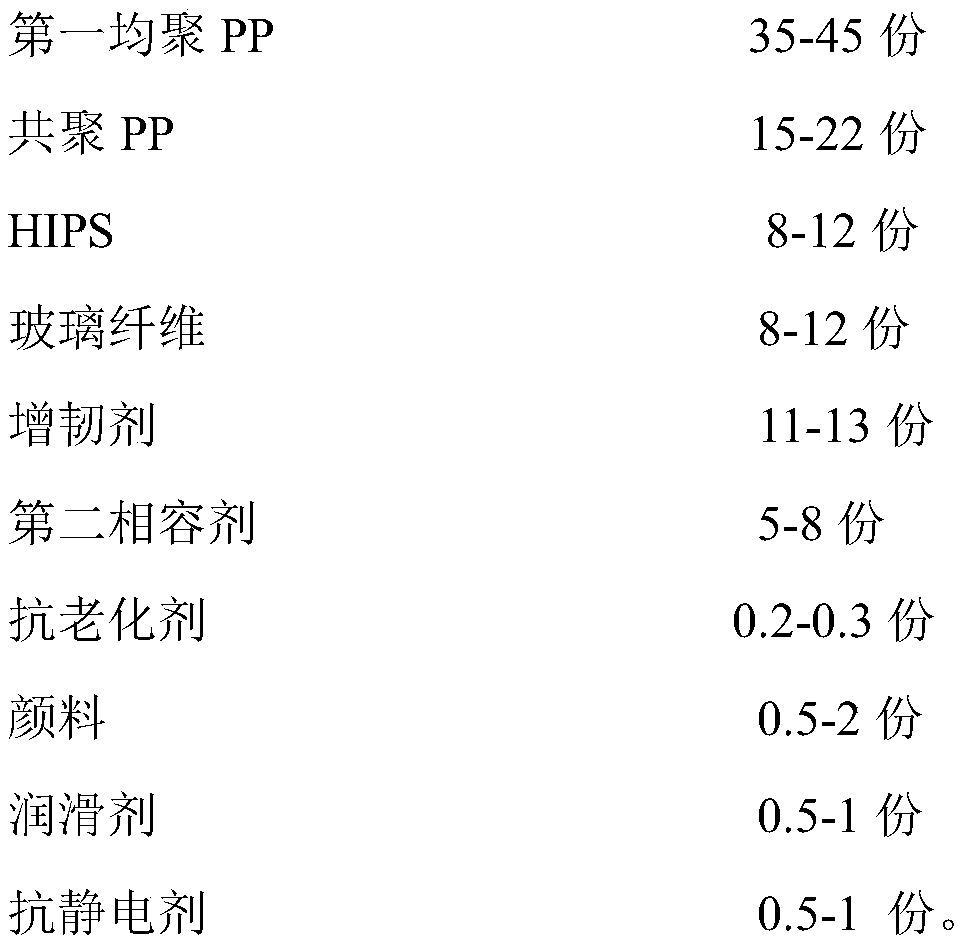

[0070] GF-1 of the present invention is prepared from the following raw materials according to weight percentage: homopolymer PP, produced by Sinopec Luoyang Branch, homopolymer PP, brand T03, with an addition amount of 43wt%; copolymerized PP, produced by Sinopec Yanshan Branch, Brand K8303, the addition amount is 21wt%; HIPS is produced by Chimei Company, the brand name is PH88, the addition amount is 8wt%; the glass fiber is produced by Shandong Taishan, the preferred brand is T635B, the addition amount is 8wt%; the toughening agent is produced by Sabic Company, preferably The grade is 5070D, and the addition amount is 11wt%; the compatibilizer is produced by Shanghai Juqi Company, the preferred brand JQ-3, and the addition amount is 7.0wt%; the anti-aging agent is three products produced by Swiss Ciba Fine Chemical Company, three kinds The products are 1010, 168 and 770 respectively, which are used after compounding, and the addition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com