Patents

Literature

50results about How to "Does not affect dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

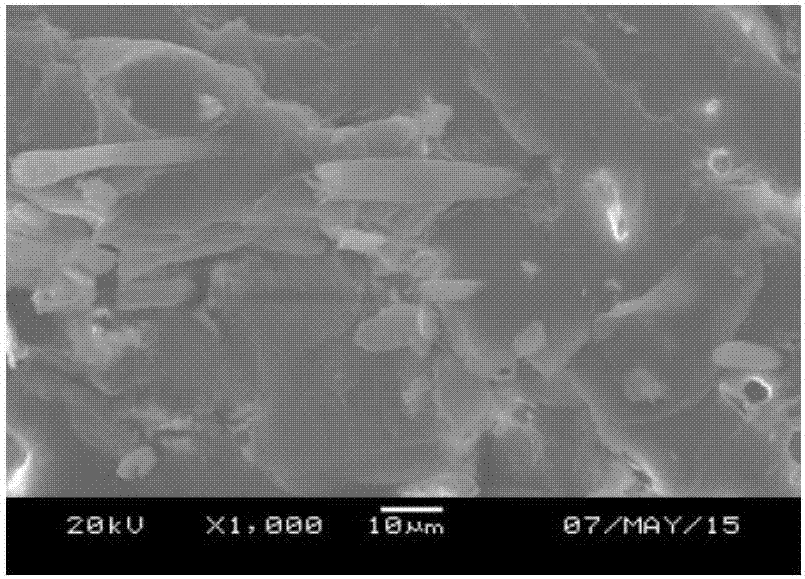

Method for manufacturing anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials

InactiveCN106346589AWhite colorGood film formingFlat articlesDomestic articlesOptoelectronicsImpurity

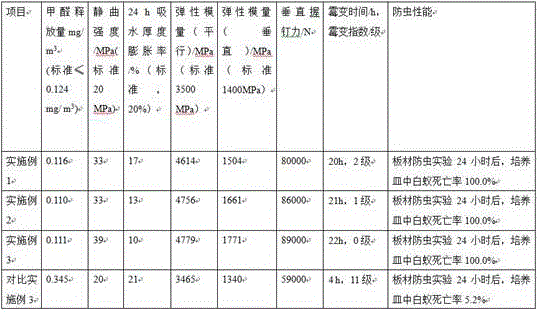

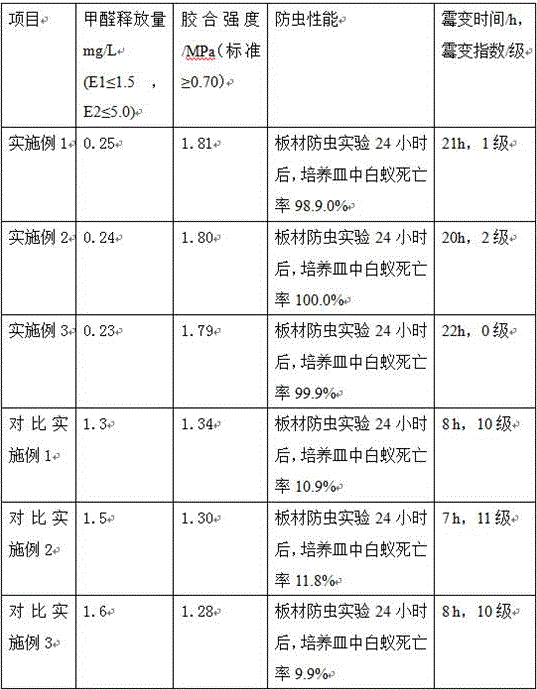

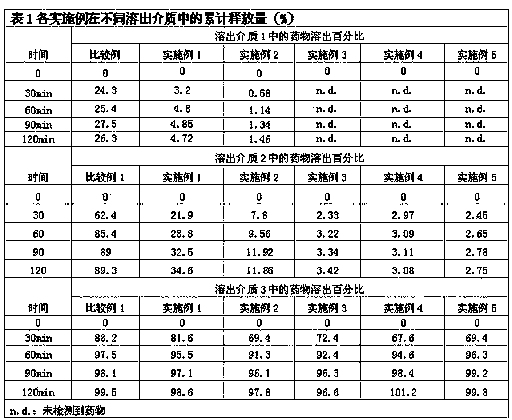

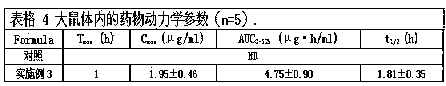

The invention discloses a method for manufacturing an anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials. The manufacturing method comprises the following steps of: preparing materials, drying, peeling and removing impurities, sorting and storing, respectively gluing on a surface core layer, hierarchically paving, in advance hot press molding, and sanding wood finishes; an isocyanate sawdust powder hybrid adhesive is coated on the surface, and an anti-insect and anti-mold composite urea-formaldehyde resin adhesive is coated on the core layer; wood shavings on the core layer are divided into three-layer structures, comprising intermediate layer of core layer, upper surface layer of core layer and lower surface layer of core layer; the intermediate layer of the core layer is paved longitudinally, and the upper surface layer of the core layer and the lower surface layer and surface layer of the core layer are paved horizontally. For the oriented strand board prepared by the method, the static bending intensity in a parallel direction is in a scope of 33-39 MPA, the parallel elasticity modulus is in the scope of 4614-4779 MPA, the vertical elasticity modulus is in the scope of 1504-1771 MPA, the thickness swelling rate of water absorption in 24 h is in the scope of 10%-17%, and the vertical nail-holding power reaches up to 89000N. In the manufacturing method, a problem that the board is easy to suffer from erosion of white ants and moths is thoroughly solved by adding an anti-insect and anti-mold additive, and the service life of the board is prolonged.

Owner:广西横县新威林板业有限公司

Preparation method and system of toner pre-dispersing material

InactiveCN102766352AIncreased toner contentDoes not affect dispersionOrganic dyesEngineeringPigment particle

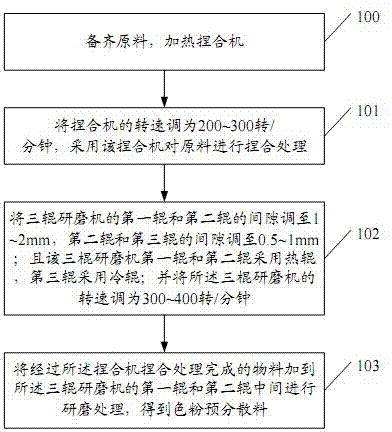

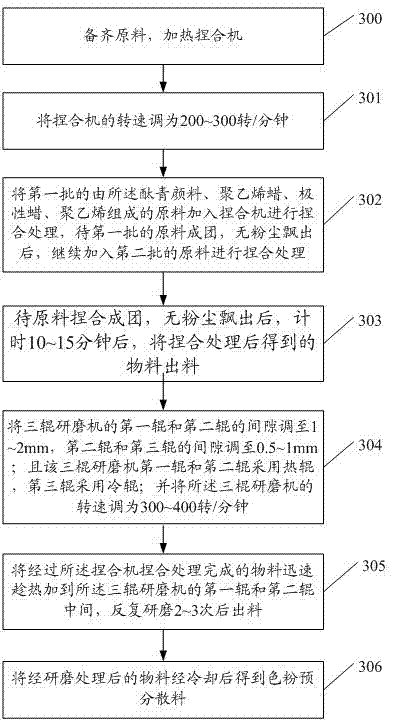

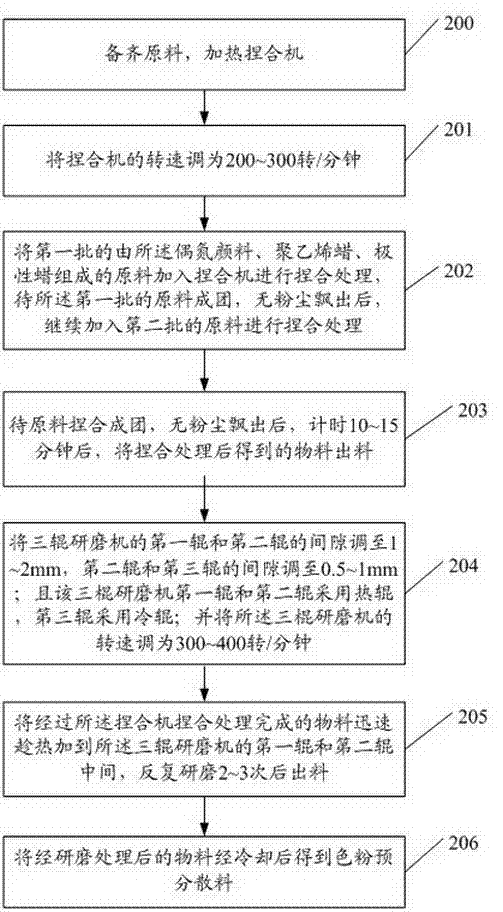

The invention provides a preparation method and a system of a toner pre-dispersing material. The method comprises preparing all raw materials and heating a kneading machine; adjusting rotation speed of the kneading machine to be 200-300 circle / minute and using the kneading machine to conduct kneading treatment on the raw materials; adjusting a gap between a first roller and a second roller of a three-roll grinder to be 1-2mm and adjusting a gap between a second roller and a third roller of the three-roll grinder to be 0.5-1mm, enabling the first roller and the second roller of the three-roll grinder to adopt hot rollers and enabling the third roller of the three-roll grinder to adopt a cold roller; adjusting rotation speed of the three-roll grinder to be 300-400 circle / minute; and adding materials treated by the kneading machine between the first roller and the second roller of the three-roll grinder, and treating and grinding the materials through the three rollers to obtain the toner pre-dispersing material. The preparation method and the system adopt the kneading machine for fusion and the three-roll grinder for repeated grinding and enable organic pigments to be sufficiently soaked and wrapped by a dispersing agent to remove harmful effects that organic pigment particles are difficult to disperse due to aggregation and the like.

Owner:广州保亮得塑料科技有限公司

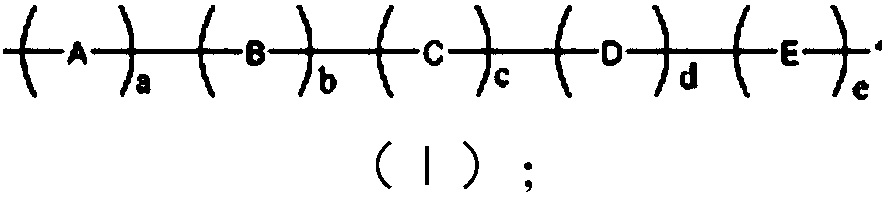

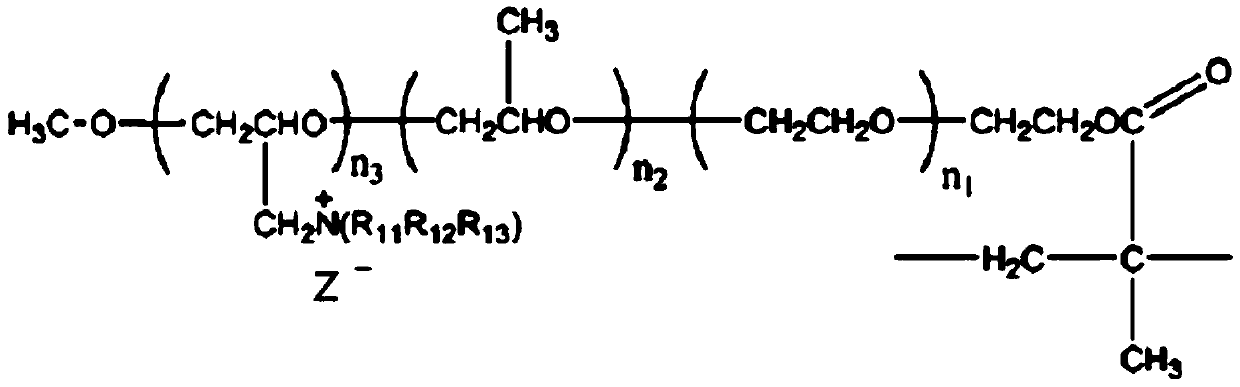

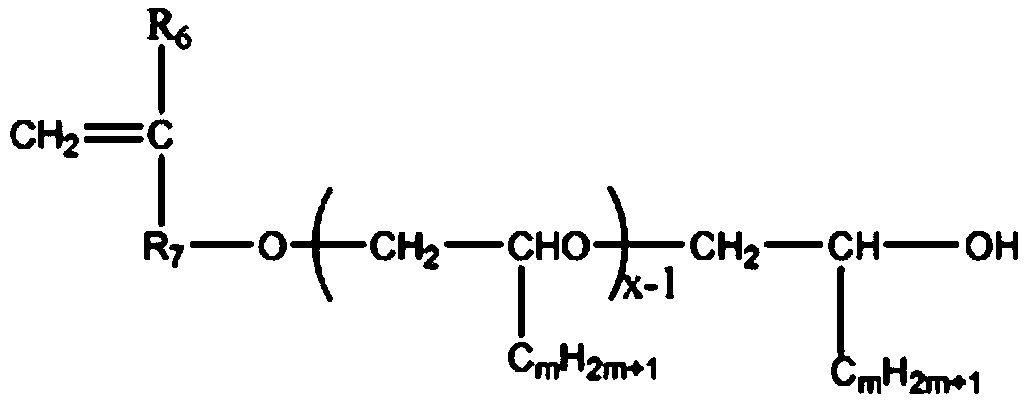

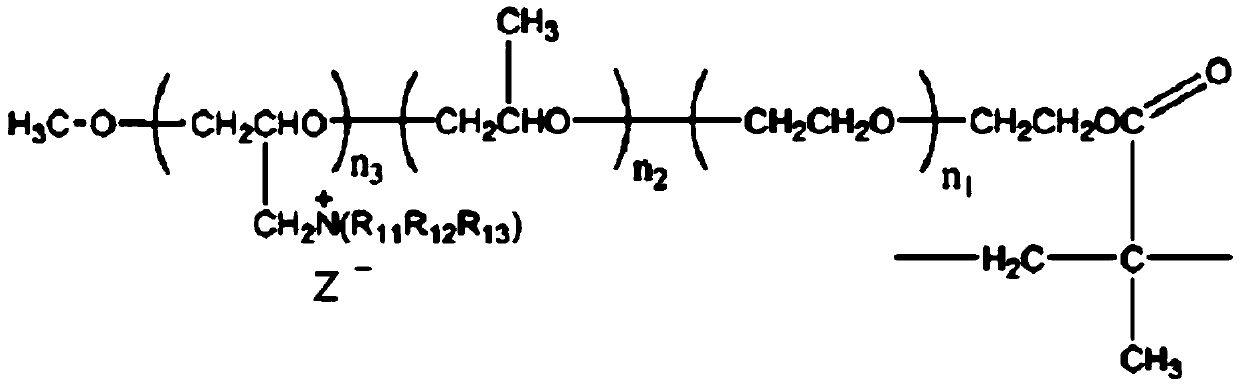

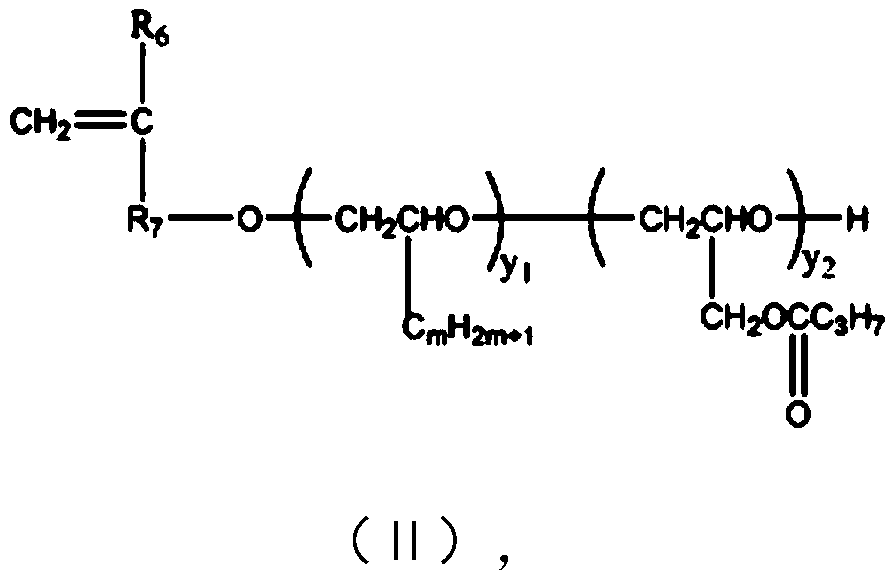

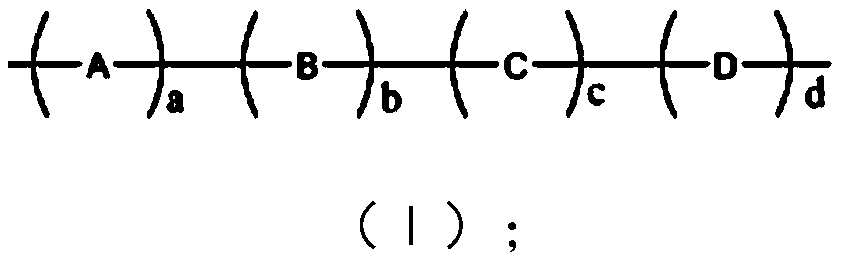

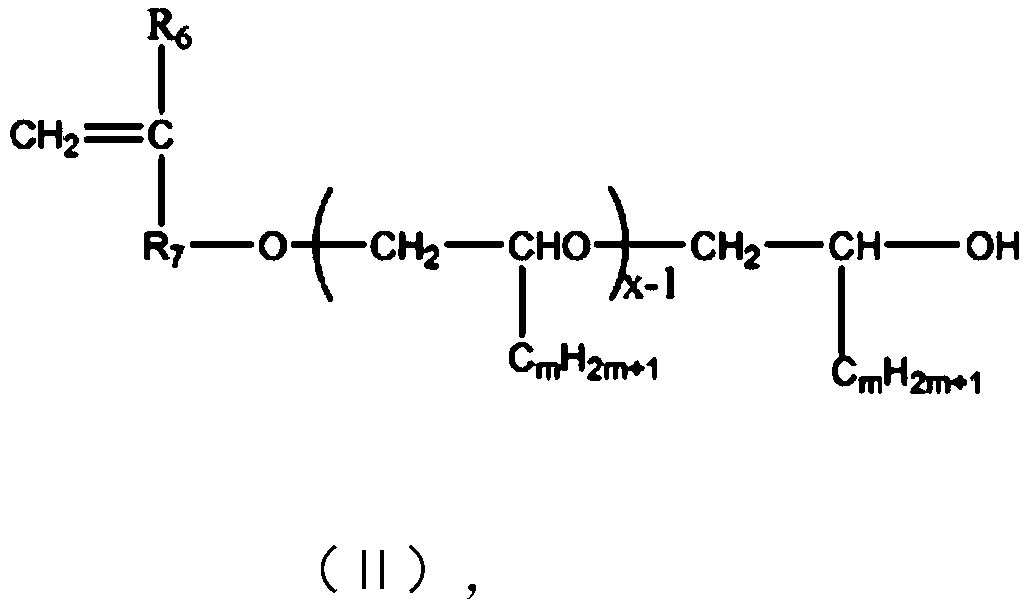

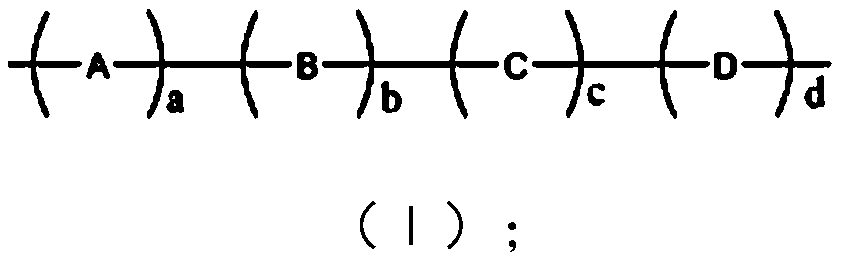

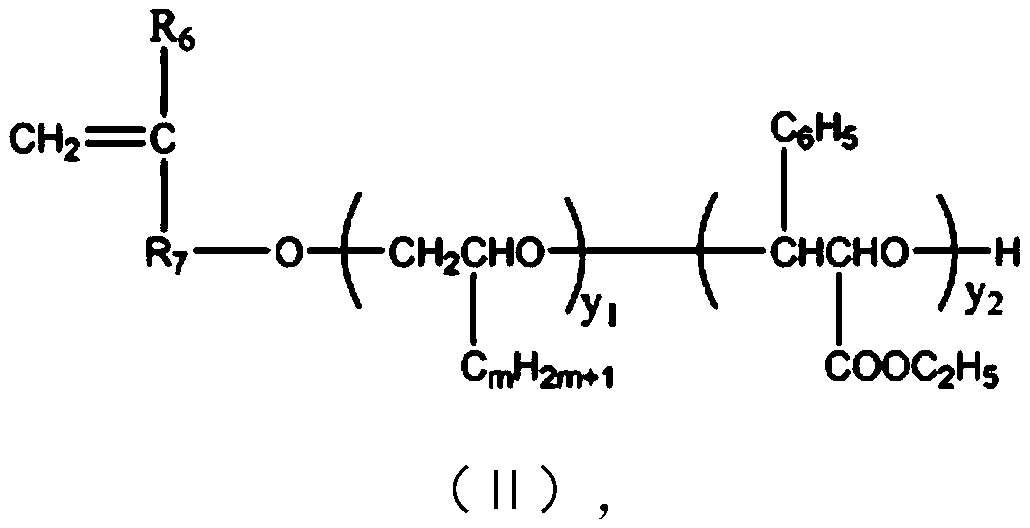

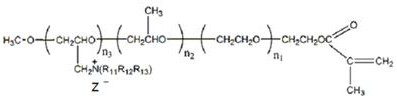

Viscosity reduction type polycarboxylic acid water reducer containing dual viscosity reduction functional groups, preparation method for viscosity reduction type polycarboxylic acid water reducer and use of viscosity reduction type polycarboxylic acid water reducer

The invention provides a viscosity reduction type active macromonomer. The invention further provides a viscosity reduction type polycarboxylic acid water reducer. According to the viscosity reductiontype polycarboxylic acid water reducer provided by the invention, all ingredients and all functional groups are in mutual synergism; compared with viscosity reduction type polycarboxylic acid water reducers synthesized in the prior art, the viscosity reduction type polycarboxylic acid water reducer has the advantages that the viscosity reduction effect is superior, and the water reducing rate isnot affected; meanwhile, a large number of hydrophobic alkyl groups and ester groups are introduced into a PEG lateral chain, so that the HLB value is lowered, the surfactivity effect is enhanced, andthe viscosity reduction type polycarboxylic acid water reducer has a good reduction effect; and concrete doped with the product provided by the invention is low in shrinkage and does not crack. The viscosity-reduction hydrophobic functional groups are located on the lateral chain, the viscosity reduction effect of the water reducer can be regulated through the content of the viscosity-reduction functional groups, however, the content of dispersion groups is not affected, the dispersion effect on cement particles is not affected, and the dispersion and water reduction effects of the water reducer are not affected.

Owner:惠州市红墙化学有限公司

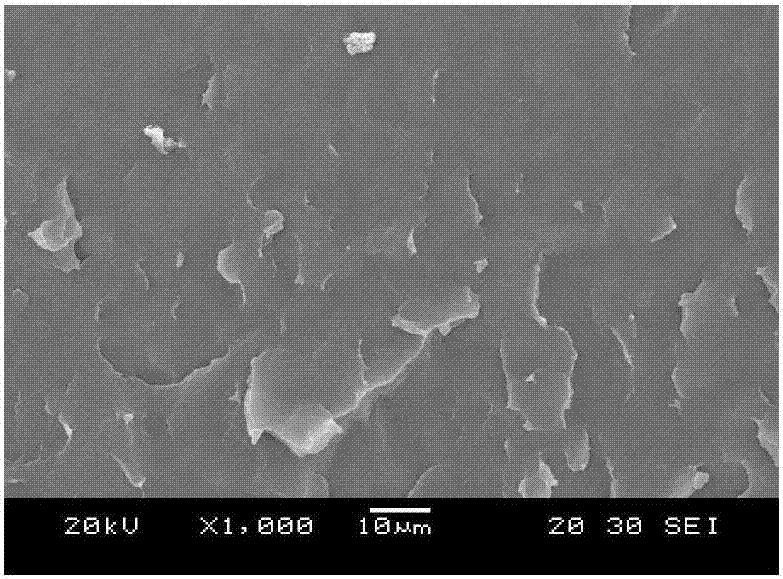

Method for producing particle board through anti-insect and anti-mold composite urea formaldehyde resin

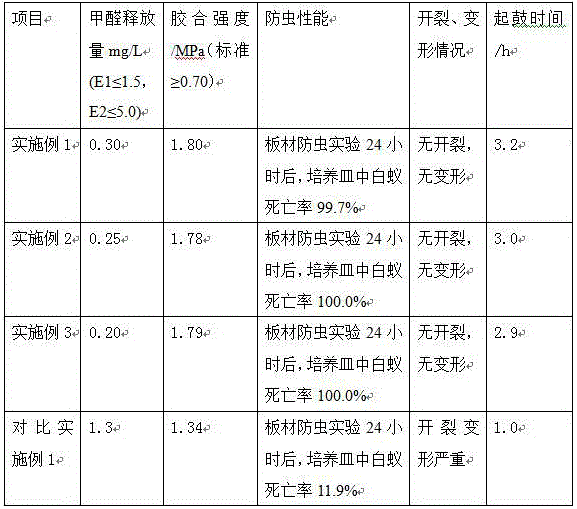

ActiveCN106363760AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesAntioxidantPolyvinyl alcohol

The invention discloses a method for producing a particle board through anti-insect and anti-mold composite urea formaldehyde resin. The method comprises the procedures like material preparation, drying, veneer removing and grit removing, mixing glue, and hot press molding. The key of the production method is that melamine modified urea formaldehyde resin is adopted as a main material of an adhesive; oxidized starch is added as a viscous complexing agent; polyvinyl alcohol is adopted as a flexibilizer; hydrogenated rosin is adopted as an antioxidant; polyisocyanate is adopted as a curing agent; and triethoxyisobutylsilane is adopted as a bridging agent. According to the method, the anti-insect and anti-mold composite urea formaldehyde resin is prepared through adopting phenolated lignin as a formaldehyde capture agent and adding an anti-insect and anti-mold agent, and the particle board produced through the anti-insect and anti-mold composite urea formaldehyde resin has the advantages that the residual amount of formaldehyde is low and the anti-insect and anti-mold effect is good, has a quite high inhibiting effect on breeding of aspergillus, trichoderma and penicillia, and has instantaneous killing force and a long-term prevention effect on board powder-post beetles.

Owner:广西横县新威林板业有限公司

Sandwich organic/inorganic hybridized microspheres and preparation method thereof

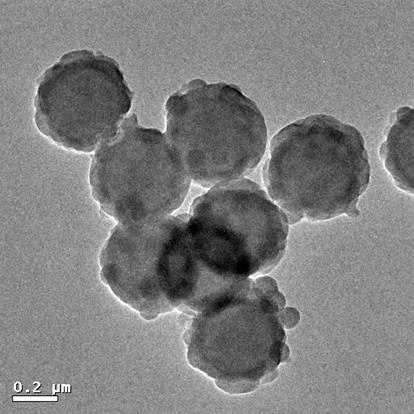

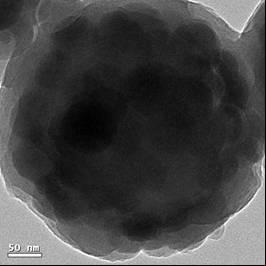

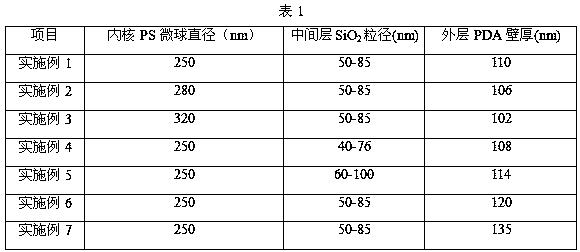

InactiveCN109317068AUniform sizeGood dispersionMicroballoon preparationMicrocapsule preparationTetraethyl orthosilicatePolystyrene microsphere

The invention belongs to the field of novel materials, and particularly relates to sandwich organic / inorganic hybridized microspheres and a preparation method thereof. The sandwich polystyrene / silicondioxide / polydopamine organic / inorganic hybridized microspheres are prepared by adopting cross-linked soft core / hard shell polystyrene microspheres as a template and successively performing hydrolysisof tetraethyl orthosilicate on the surface of microspheres and polymerization of dopamine on the surface of the microspheres. The sandwich organic / inorganic hybridized microspheres prepared by adopting the preparation method of the invention have the characteristics of uniform size, good dispersity, capability of adjusting the thickness of each layer, different chemical components of all layers and the like and have high innovation in the aspect of hybridized microspheres preparation.

Owner:ZHENGZHOU UNIV

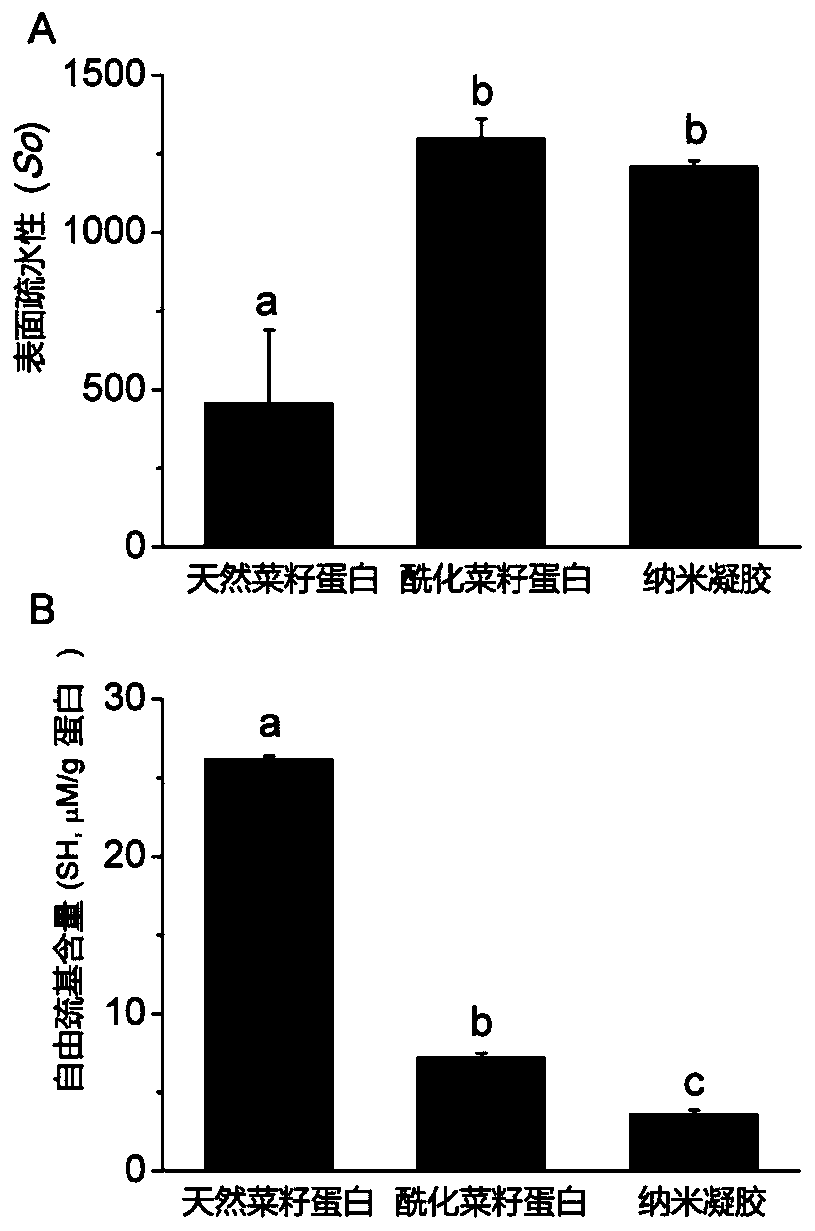

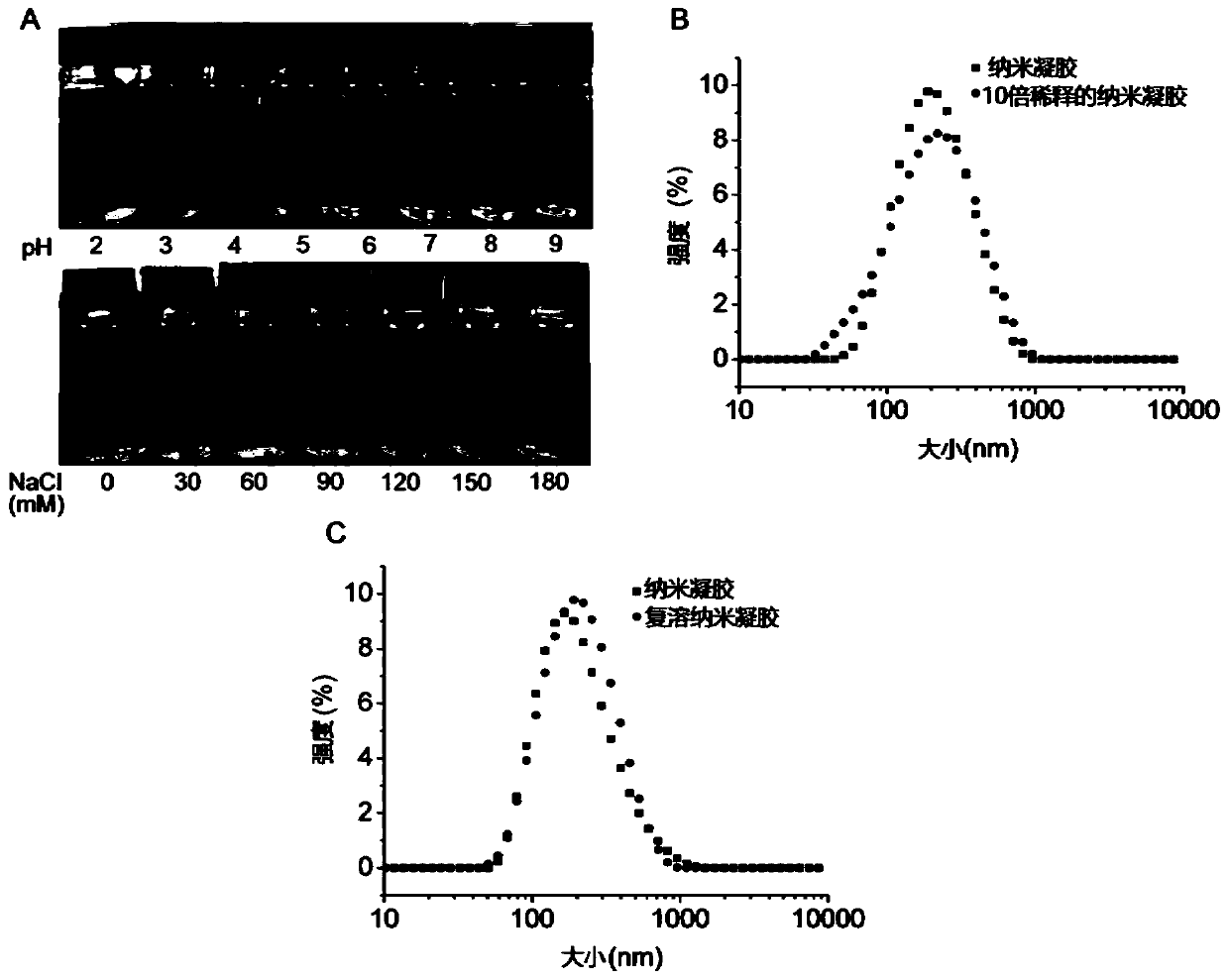

Rapeseed protein-based nanogel and application thereof

InactiveCN110483812AGood water resolubilityGood biocompatibilityAerosol deliveryOintment deliveryProtein solutionCrystallography

The invention provides rapeseed protein-based nanogel and application thereof, and belongs to the field of nano functional materials. The rapeseed protein-based nanogel is prepared by the following method: performing acylation reaction on rapeseed protein and succinic anhydride to obtain acylated rapeseed protein; adjusting the pH value of the acylated rapeseed protein aqueous solution, heating and quickly cooling the solution. The invention also provides curcumin-loaded rapeseed protein-based nanogel which is prepared by the following method: carrying out acylation reaction on rapeseed protein and succinic anhydride to obtain acylated rapeseed protein; adjusting the pH value of the acylated rapeseed protein aqueous solution, dropwise adding a curcumin solution into the protein solution, and heating and rapidly cooling the mixture; and removing free curcumin to obtain the curcumin-loaded rapeseed protein-based nanogel. The nanogel has good water resolubility and biocompatibility, is uniform in size distribution and high in stability, can efficiently embed hydrophobic active substance curcumin, remarkably improves the anti-tumor activity of curcumin, and improves the bioavailabilityof curcumin.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

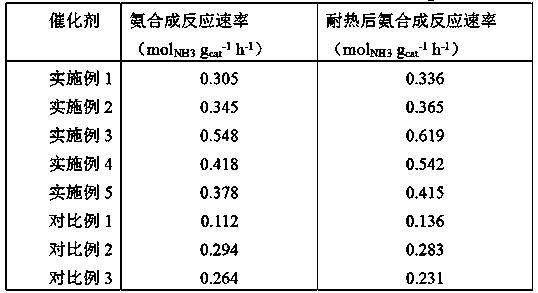

Preparation method for activated-carbon-supported ruthenium-based ammonia synthesis catalyst

InactiveCN108970610ADoes not affect dispersionHigh activityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsActivated carbonNitrogen

The invention discloses a preparation method for an activated-carbon-supported ruthenium-based ammonia synthesis catalyst. According to the preparation method, heat treatment is carried out on an activated-carbon-supported ruthenium-based catalyst containing an auxiliary for 0.2-30 hours in mixed gas composed of nitric acid gas and oxygen-free gas at 70-300 DEG C so as to obtain the activated-carbon-supported ruthenium-based ammonia synthesis catalyst, in the mixed gas, the volume ratio of the nitric acid gas is 1-90 vol%, the oxygen-free gas is mixed gas of nitrogen and one or more of zero-group inert gas in any proportion. Compared with the activated-carbon-supported ruthenium catalyst prepared through a traditional method, the catalyst has the advantages of being relatively high in ammonia synthesis activity and thermal stability and good in industrial application prospect.

Owner:FUZHOU UNIV

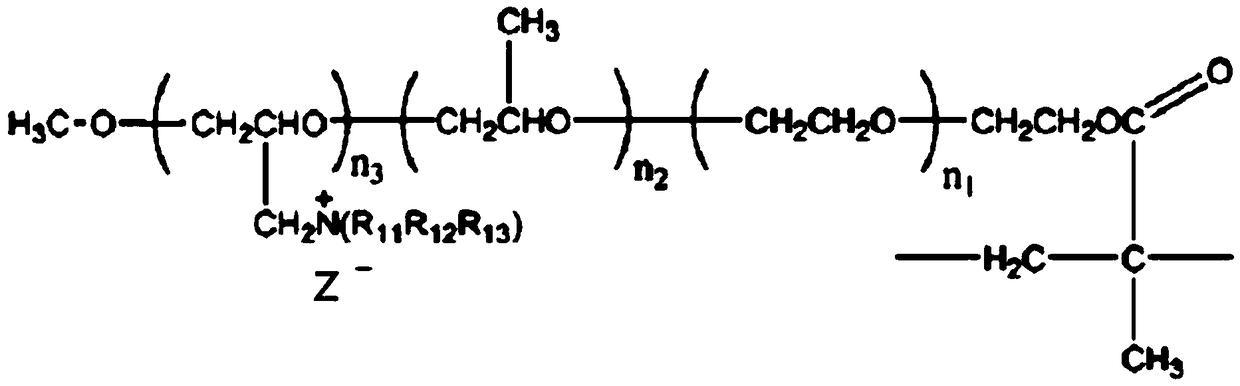

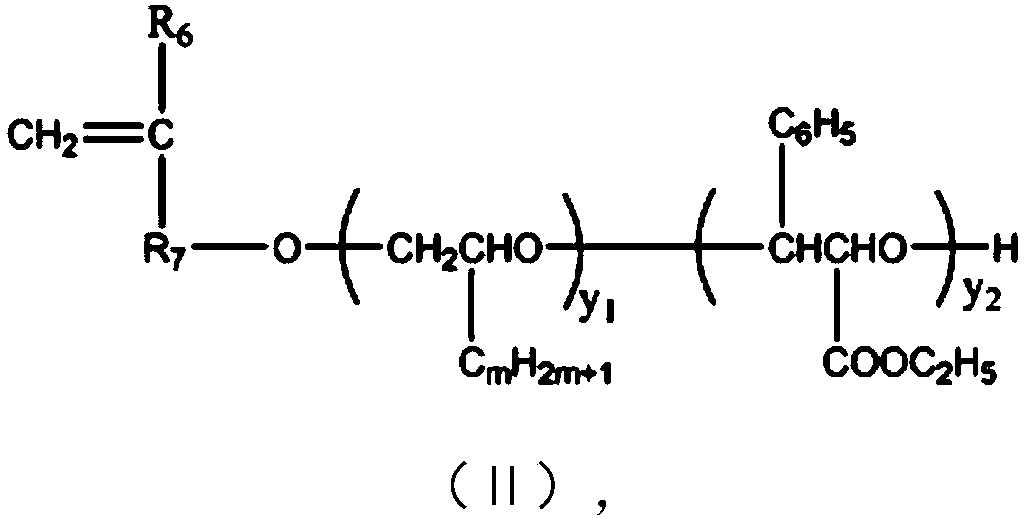

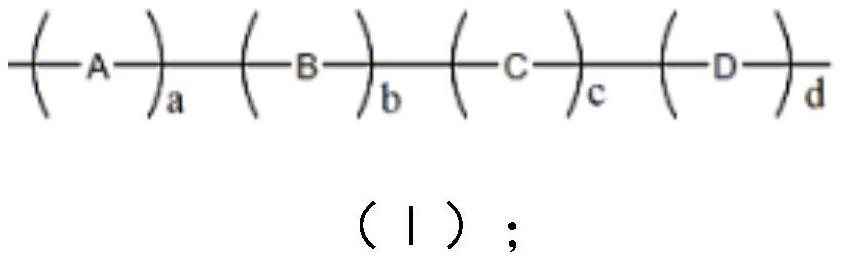

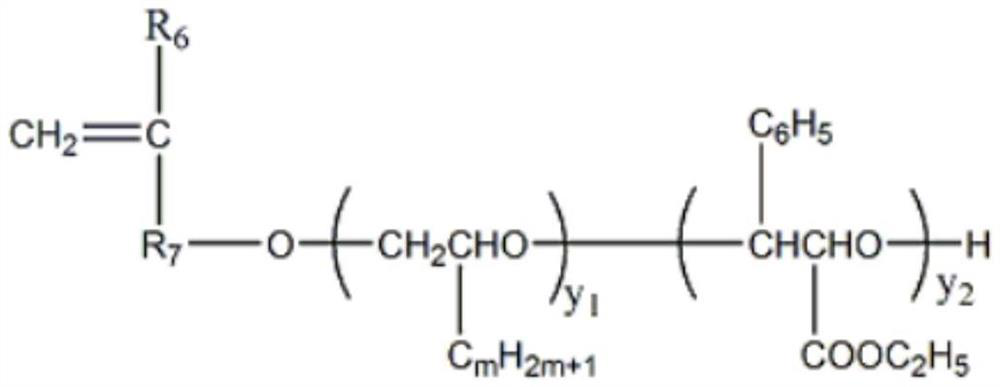

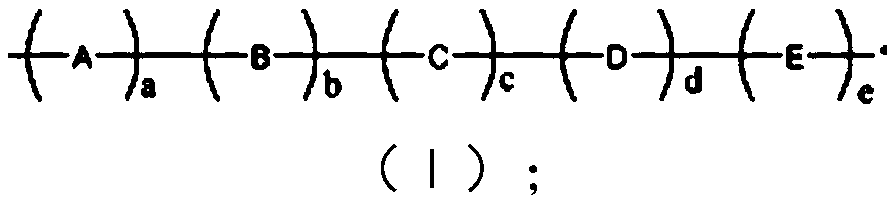

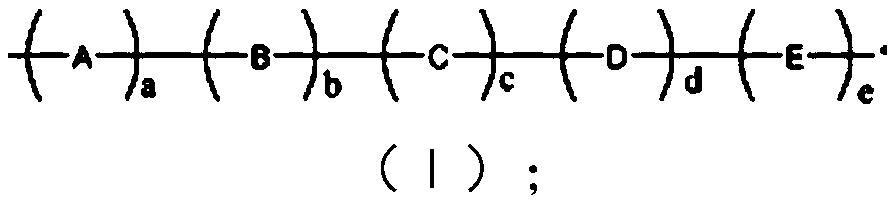

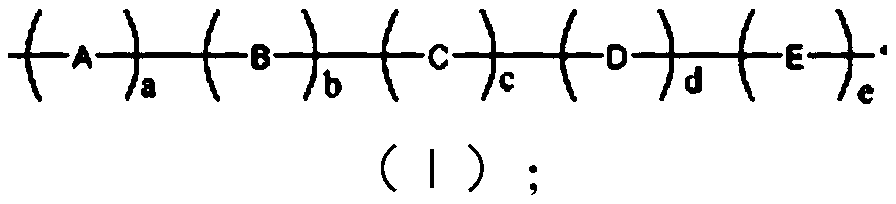

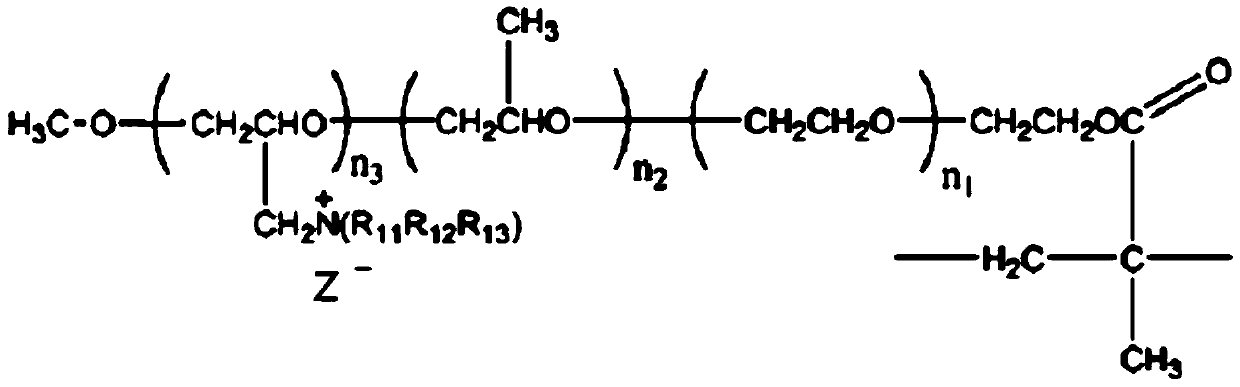

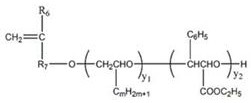

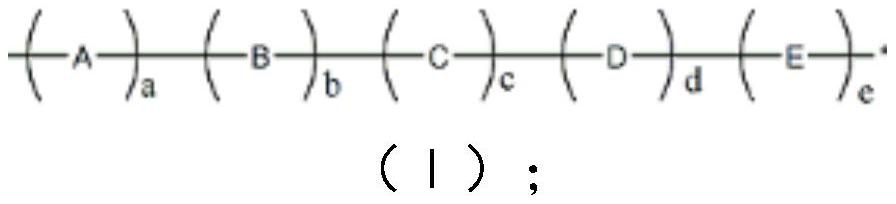

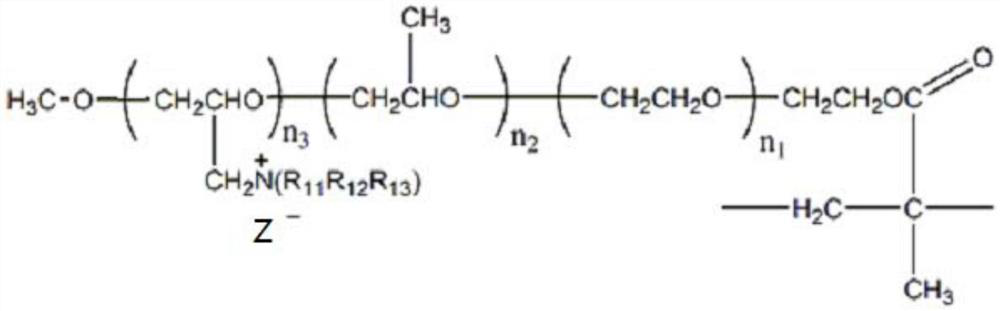

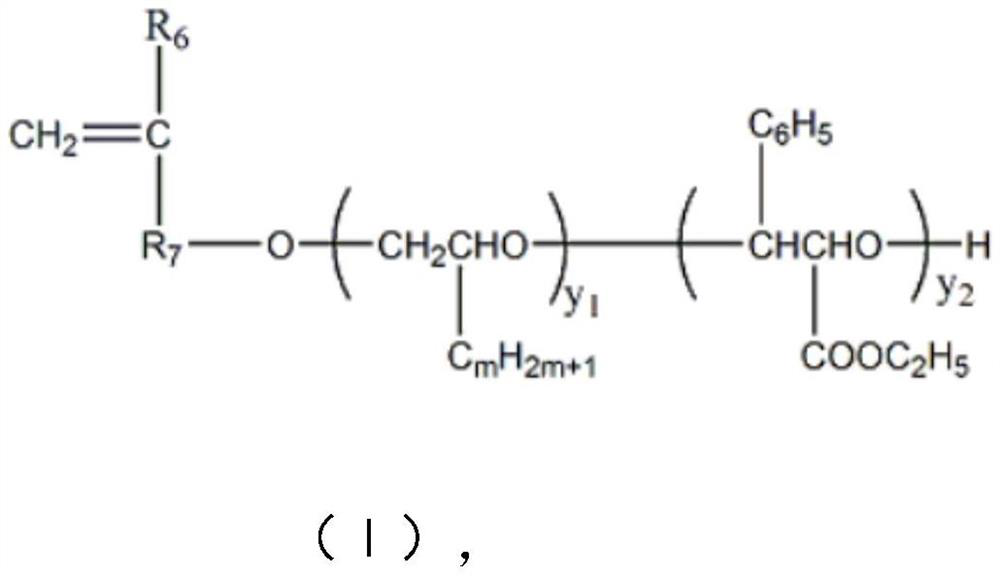

Application of early-strength viscosity-reducing type polycarboxylic acid water-reducing agent in preparation of prefabricated member concrete

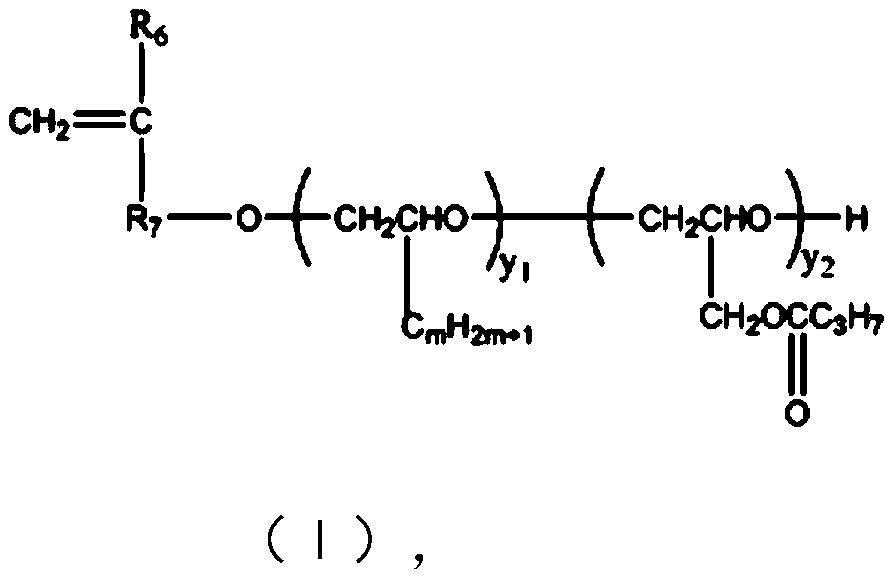

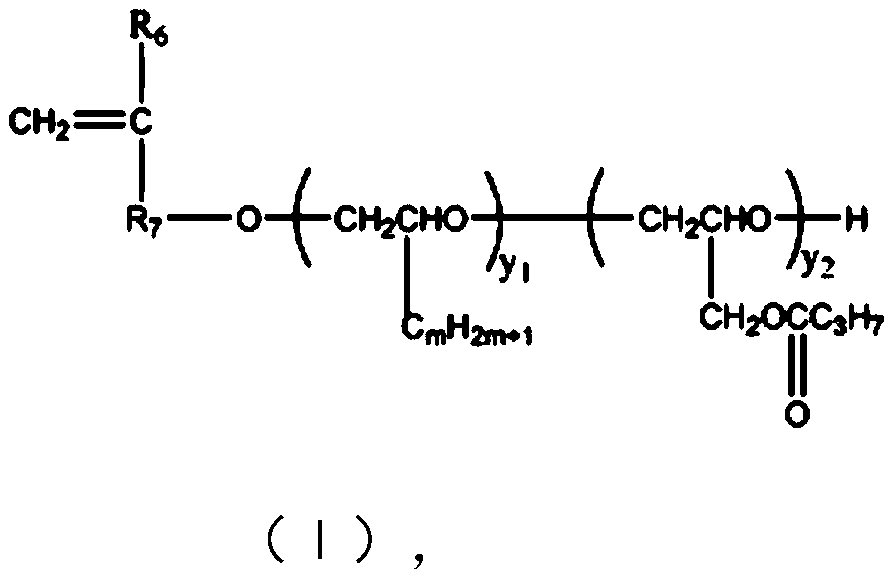

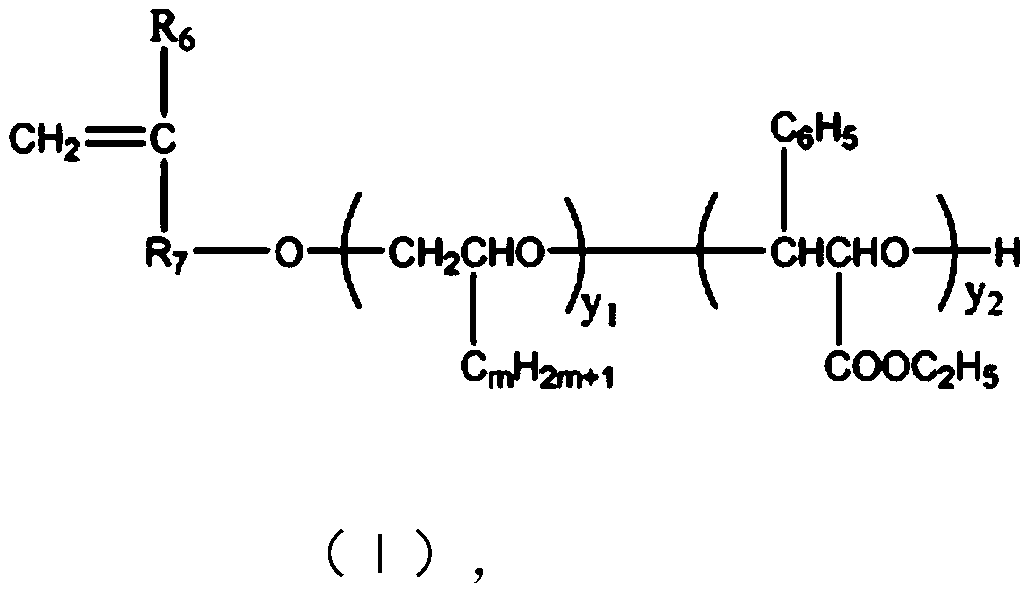

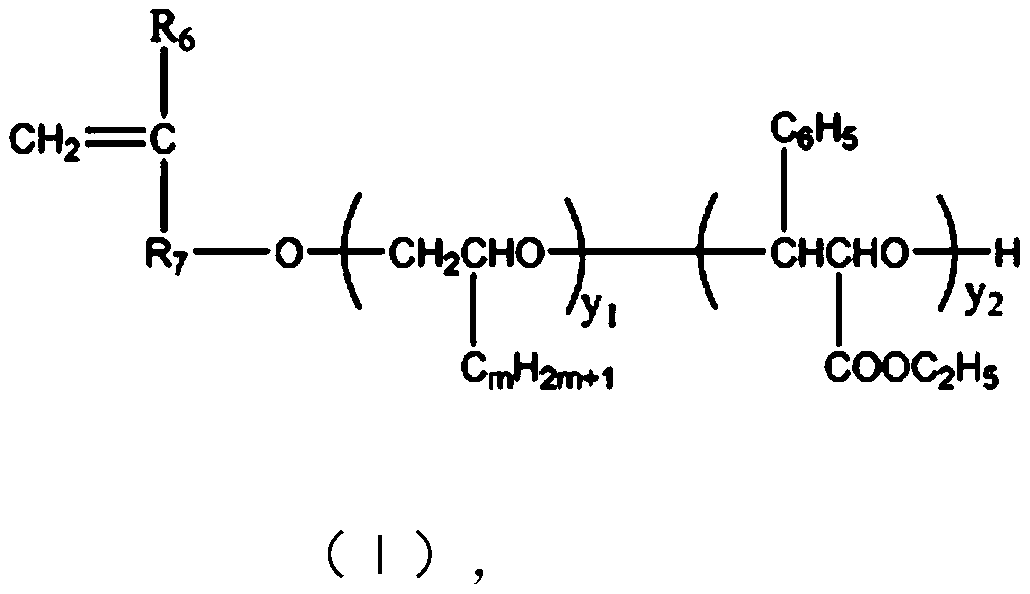

The invention provides concrete and also provides an application of an early-strength viscosity-reducing type polycarboxylic acid water-reducing agent of Formula (I) in preparation of prefabricated member concrete. The prefabricated member concrete produced by using the early-strength viscosity-reducing type polycarboxylic acid water-reducing agent of Formula (I) is soft in texture, easy in distribution and good in slump retention; after the construction is finished, the concrete can lose flowability instantaneously, initial setting and final setting are rapid and the early-strength development is fast. The application provided by the invention has the beneficial effects that no steaming and curing or no pressure steaming and curing is realized, and a production process with normal-temperature natural curing is adopted, so that the mold turnover period is shortened, the energy is saved and the environment is protected.

Owner:GUANGDONG REDWALL NEW MATERIALS

Application of viscosity-reducing polycarboxylate water reducer in preparation of tailings sand concrete

ActiveCN109455975BRegulated contentAdjust viscosity reduction effectEngineeringEnvironmental engineering

The invention provides a kind of concrete, and the invention also provides the application of the viscosity-reducing polycarboxylate water reducer of formula (I) in the preparation of tailings sand concrete. The invention adopts tailings sand and machine-made sand mixed sand, and formula ( Ⅰ) The viscosity-reducing polycarboxylate superplasticizer is used together to overcome the technical defects of iron tailings sand concrete. Through the combined use of tailings sand and machine-made sand, the gradation and fineness modulus of the sand can be adjusted. The sticky admixture adjusts the cohesion and fluidity of concrete, improves the workability of concrete, especially the cohesion and water retention of concrete, reduces segregation and bleeding, and can produce tailings sand concrete that meets construction requirements. The utilization rate of iron tailings was promoted.

Owner:河北红墙新材料有限公司

High-efficiency purification method of water-dispersed carbon nanomaterial

ActiveCN110589806AGood dispersionEffective dispersionFullerenesCarbon nanotubesWater dispersiblePurification methods

The invention provides a high-efficiency purification method of a water-dispersed carbon nanomaterial. A ball-milling mixture of a carbon nanomaterial, water-soluble azo dye molecules and derivable modifiable molecules is dissolved with water, and then mixed well with an inorganic salts / aqueous alkali, centrifugation is conducted for 1-30 minutes at the centrifugal speed of 3000-10000 rounds / minute, a supernatant dye solution is sucked out, and then water is added to ultrasonically dissolve bottom precipitation; and the salting-out assisted centrifugation purification process is repeated untila product is washed, and a carbon nanomaterial dispersed in the water is obtained. The high-efficiency purification method has the outstanding characteristics that common alkali and salt are used asan auxiliary settling agent, in a short time and at a low centrifugal speed, high-efficiency separation of free-state dye molecules from the water-dispersed carbon nanomaterial can be realized, in thepurification process of the water-dispersed carbon nanomaterial, the loss of the carbon nanomaterial is small, a purification reagent is environment-friendly, the cost is low, and the purification process has no effect on the physical and chemical properties of the carbon nanomaterial such as the water dispersibility and the photoelectric performance.

Owner:WUHAN UNIV

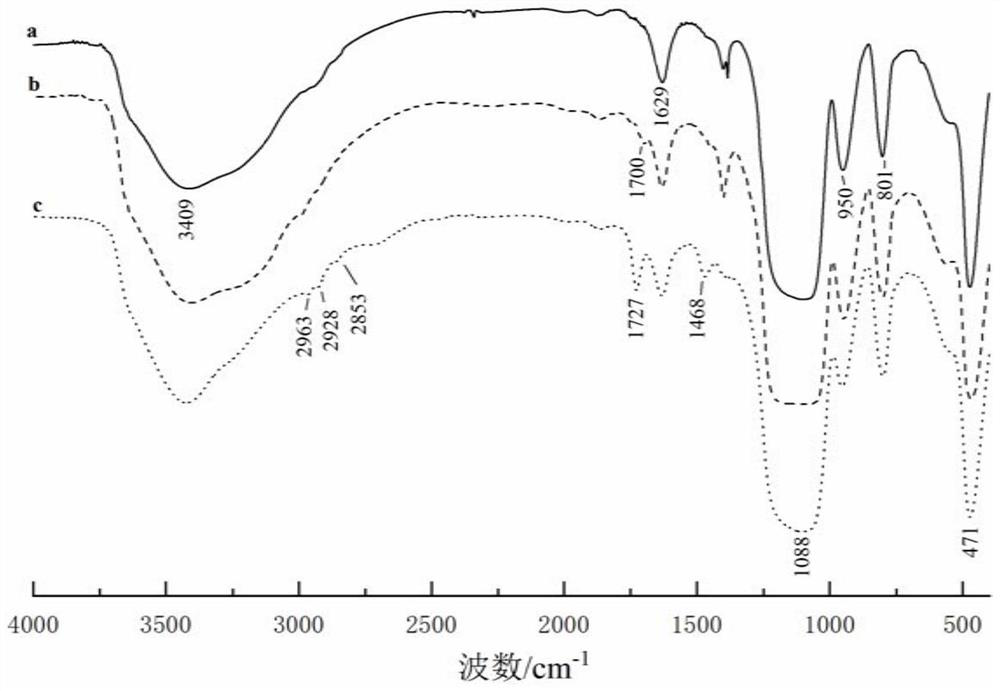

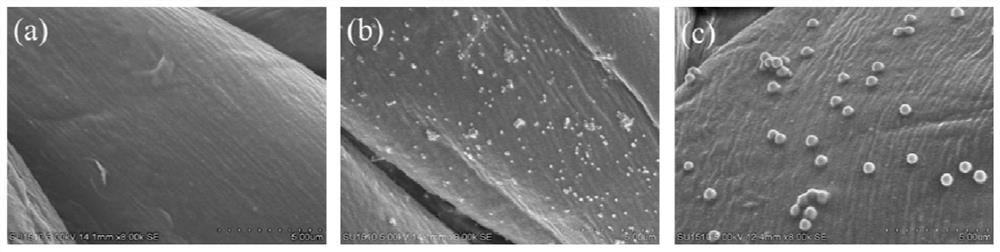

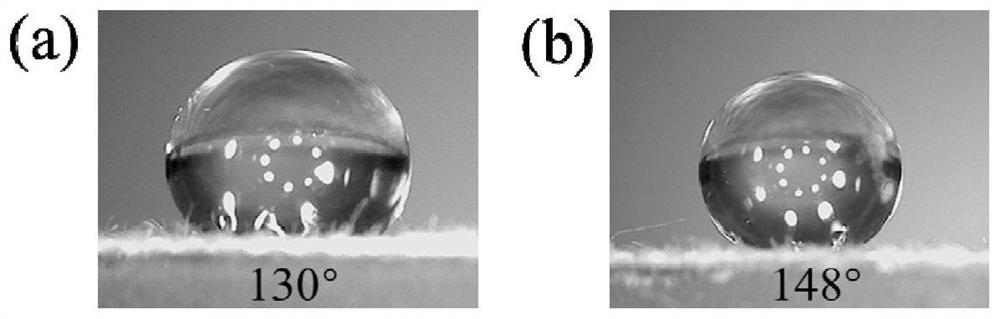

Compound water repellent containing tertiary amine polymer brush grafted nano silicon dioxide

ActiveCN111944106ASmall particle sizeNarrow particle size distributionLiquid repellent fibresVegetal fibresPolymer scienceCotton fibre

The invention discloses a compound water repellent agent containing tertiary amine polymer brush grafted nano silicon dioxide, and belongs to the field of environment-friendly textiles. According to the invention, specific tertiary amine polymer brush graft modified nano-silica is facilitated, and the polymer brush graft modified nano-silica has good water dispersibility, can be doped, mixed and compounded with a cationic water repellent to obtain the water repellent, and does not influence the stability of the emulsion. After fabric is treated by the obtained compound water repellent, the water repellent is adsorbed on the surface of cotton fiber due to electrostatic interaction and is covered by a water repellent film, so that the compound water repellent has excellent capacity of improving the surface roughness of the fiber, the hydrophobic property of the water repellent can be effectively improved, the use amount of the water repellent is reduced to a certain extent, and the problem of environmental pollution in the use process of the water repellent is solved.

Owner:QINGDAO UNIV

Alkyl-containing early strength viscosity reduction type polycarboxylic acid water reducer and preparation method thereof

The invention provides an early strength viscosity reduction type polycarboxylic acid water reducer. According to the synthesized early strength viscosity reduction type polycarboxylic acid water reducer, cooperative interaction is present between components and between functional groups. Compared with the early strength viscosity reduction type polycarboxylic acid water reducer synthesized in theprior art, early strength and viscosity reduction effects are excellent, water-reducing rate cannot be affected, a lot of hydrophobic alkyl is introduced in a PEG (polyethylene glycol) side chain, aHLB (hydrophile-lipophile balance) value is reduced, surface activity effects are enhanced, and good shrinkage reducing performance is achieved. The water reducer has the advantages that cement hydration is effectively facilitated, and early strength development of concrete is improved. The water reducer has good water-reducing rate and holding capacity of slump degree. Early strength and hydrophobic viscosity reduction functional groups are positioned on the side chain, the contents of viscosity reduction and early strength functional groups are adjusted, so that early strength and viscosityreduction effects of the water reducer can be adjusted, dispersion effects of cement particles cannot be affected by dispersion groups, and dispersion and water reducing effects of the water reducer cannot be affected.

Owner:广西红墙新材料有限公司

Preparation method of highly-wear-resistant CNF/PMMA composite material

The invention discloses a preparation method of a highly-wear resistant CNF / PMMA composite material. The preparation method is basically characterized by comprising the following steps: pre-coating cellulose nano-filaments as a matrix in PMMA at a higher concentration, preparing composite material master batches and then preparing the master batches and the PMMA into the highly-wear-resistant CNF / PMMA composite material through a melt extrusion method according to a certain proportion. By utilizing the cellulose nano-filaments as a reinforcing phase, the wear resistance of the PMMA composite material can be significantly improved under the premise that the light transmittance is not affected; the obtained highly-wear-resistant CNF / PMMA composite material has potential applications in the fields of electronic screens, aerospace non-structural materials and the like.

Owner:TIANJIN UNIV OF SCI & TECH

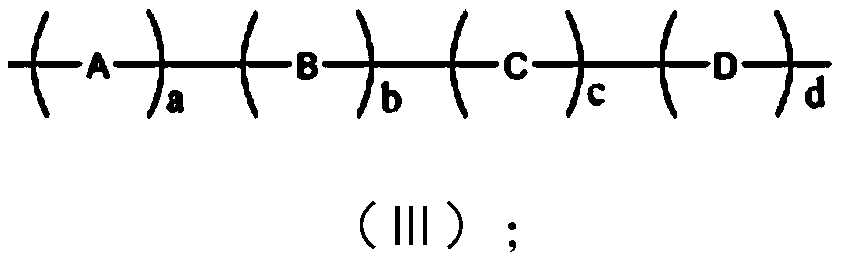

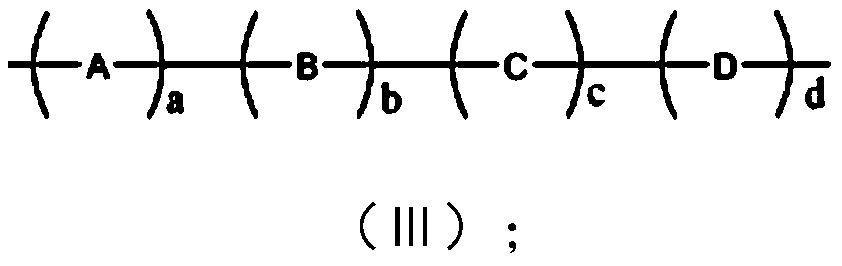

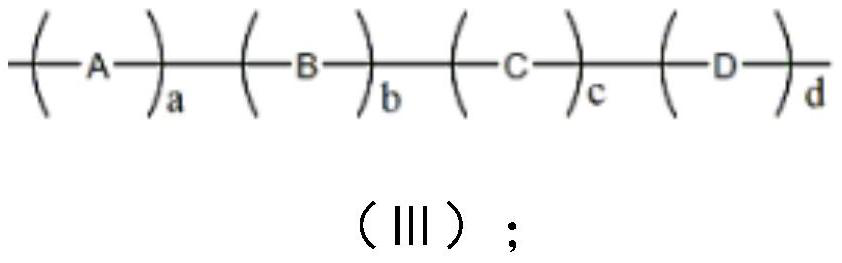

Early strength and viscosity reduction type polycarboxylate superplasticizer containing double viscosity-reduction functional groups and preparation method of polycarboxylate superplasticizer

The invention provides an early strength and viscosity reduction type polycarboxylate superplasticizer. Components and functional groups of the synthesized early strength and viscosity reduction typepolycarboxylate superplasticizer have a synergistic effect, compared with the early strength type polycarboxylate superplasticizer synthesized in the prior art, the early strength and viscosity reduction type polycarboxylate superplasticizer have excellent early strength and viscosity reduction effects while the water reducing rate is not affected, meanwhile, a large quantity of hydrophobic alkylgroups, phenyl groups and ester groups are introduced into PEG side chains, so that HLB value is reduced, the surface activity effect is enhanced, and the polycarboxylate superplasticizer has good shrinkage reducing performance. The superplasticizer has good effects of promoting cement hydration and improving early strength development of concrete; the superplasticizer has good water reducing rateand slump retaining capacity. Early strength and hydrophobic viscosity reduction functional groups of the superplasticizer are located on the side chains, so that the early strength and viscosity reduction effects of the superplasticizer can be adjusted by adjusting content of the viscosity reduction and early strength functional groups while the cement particle dispersing effect of dispersing groups is not affected, and the dispersing and water reducing effects of the superplasticizer are not affected.

Owner:GUANGDONG REDWALL NEW MATERIALS

Application of viscosity-reducing polycarboxylate superplasticizer containing alkyl in preparation of C100 concrete

ActiveCN109776034AHigh water reduction rateSignificant viscosity reduction and shrinkage reduction effectSuperplasticizerMaterials science

The invention provides concrete. The concrete contains the viscosity-reducing polycarboxylate superplasticizer synthesized in the invention. The invention also provides an application of the viscosity-reducing polycarboxylate superplasticizer shown in a formula (I) in preparation of C100 concrete. Compared with the prior art, the C100 concrete prepared by using the viscosity-reducing polycarboxylate superplasticizer provided by the invention has the advantages of no segregation, no bleeding and no bottom peeling, good age slump retention, good fluidity, good workability, soft material withoutbottom sticking, proper viscosity, good compactness of concrete and high strength.

Owner:GUANGDONG REDWALL NEW MATERIALS

Viscosity reduction type polycarboxylate water reducing agent with three viscosity reduction functional groups, method for preparing viscosity reduction type polycarboxylate water reducing agent and application thereof

The invention provides a viscosity reduction type active macromonomer, and further provides a viscosity reduction type polycarboxylate water reducing agent. Compared with synthetic viscosity reductiontype polycarboxylate water reducing agents in the prior art, the viscosity reduction type polycarboxylate water reducing agent has the advantages that synergistic effects can be realized between various components and between various functional groups in the synthetic viscosity reduction type polycarboxylate water reducing agent, excellent viscosity reduction effects can be realized by the viscosity reduction type polycarboxylate water reducing agent, but influence on the water reducing ratio is prevented; large quantities of hydrophobic alkyl, ester and phenyl are led into PEG (polyethyleneglycol) side chains, accordingly, the HLB (hydrophile-lipophile balance) value can be effectively lowered, surface activity effects can be enhanced, good shrinkage reducing effects can be realized, and concrete with the added viscosity reduction type polycarboxylate water reducing agent is low in shrinkage and free of cracking; the viscosity reduction hydrophobic functional groups are positioned on the side chains, the viscosity reduction effects of the viscosity reduction type polycarboxylate water reducing agent can be adjusted by the aid of the contents of the viscosity reduction functionalgroups, but the influence on the contents of dispersion groups and influence on cement particle dispersion effects can be prevented, and accordingly influence on dispersion and water reducing effectsof the viscosity reduction type polycarboxylate water reducing agent can be prevented.

Owner:河北红墙新材料有限公司

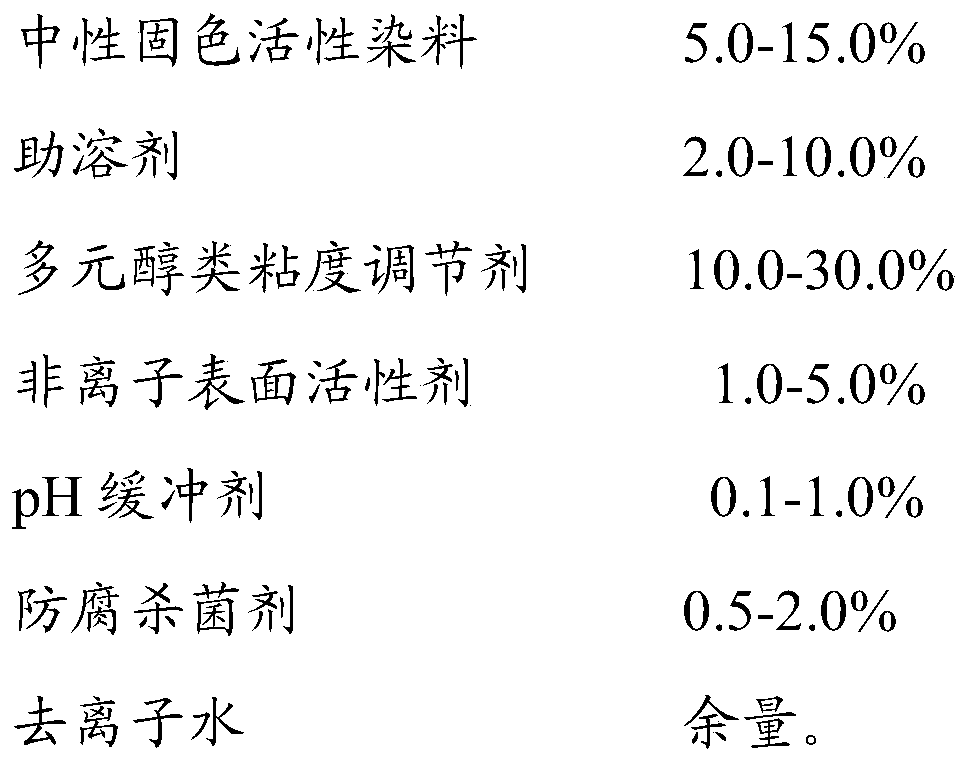

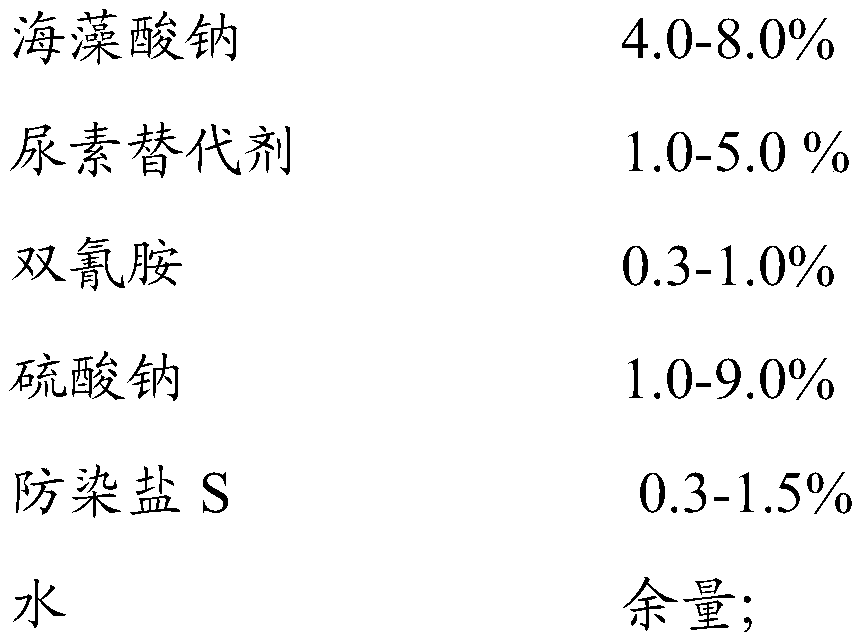

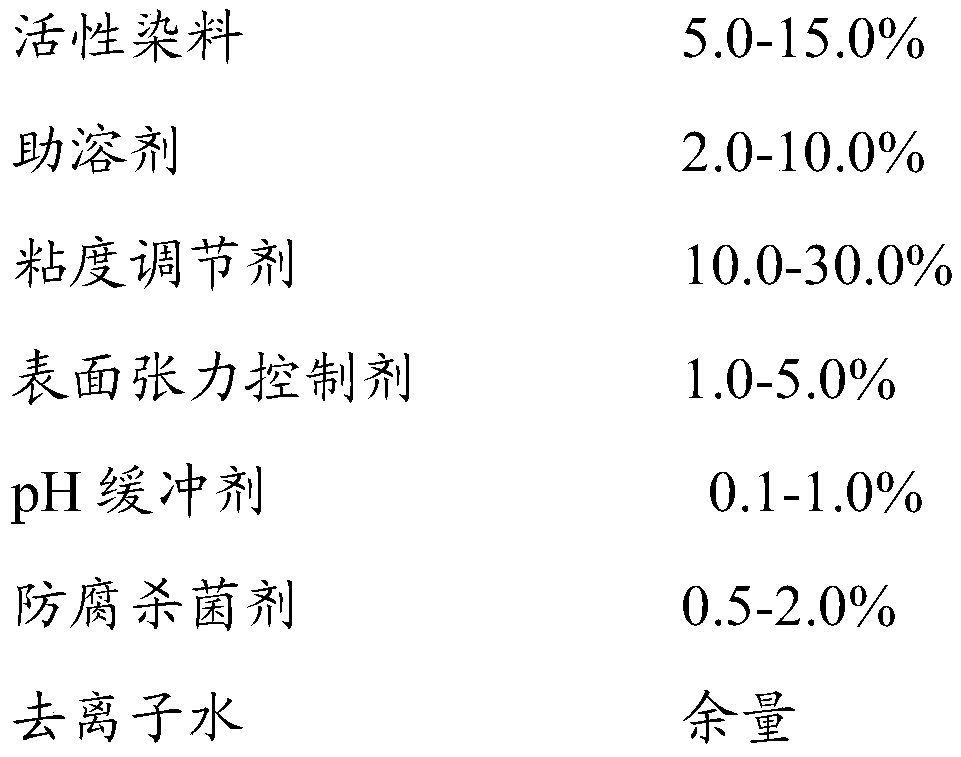

Digital printing method for active ink and multi-component fiber fabric

InactiveCN110437675AIndicators are stableAchieve color fixationInksDyeing processPolyesterCellulose fiber

The invention relates to a digital printing method for an active ink and a multi-component fiber fabric and belongs to the technical field of dyeing and printing of fabrics. The active ink comprises an active dye, a cosolvent, a viscosity adjusting agent, a surface tension control agent, a pH value buffer agent, an anti-corrosion sterilization agent and deionized water. The ink is adopted for digital printing on polyester / cellulose multi-component fiber fabrics of different ratios, polyesters and cellulose fibers can be subjected to jet printing of any color, the polyesters and the cellulose fibers are slightly contaminated, and the color fastness, the color yield and the fineness of printed patters are all high.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

Early-strength viscosity-reducing polycarboxylate superplasticizer containing three viscosity-reducing functional groups and preparation method thereof

The invention provides an early-strength viscosity-reducing polycarboxylate superplasticizer. Compared with the viscosity-reducing polycarboxylate superplasticizer synthesized in the prior art, the early-strength viscosity-reducing polycarboxylate superplasticizer synthesized in the invention has the advantages of excellent viscosity-reducing effect and no influence on the water reducing rate dueto synergistic effects between components and between functional groups; at the same time, due to the introduction of a large number of hydrophobic alkyl groups, phenyl groups and ester groups in a PEG side chain, the HLB value is reduced, the surface activity effect is enhanced, and the polycarboxylate superplasticizer provided by the invention has good shrinkage reducing performance. The polycarboxylate superplasticizer provided by the invention has good effects of promoting cement hydration and improving early strength development of concrete. Early-strength and hydrophobic viscosity-reducing functional groups of the polycarboxylate superplasticizer provided by the invention are located on a side chain, and the early-strength and viscosity-reducing effects of the polycarboxylate superplasticizer can be adjusted by adjusting the content of viscosity-reducing and early-strength functional groups, but a dispersing effect of dispersing groups on cement particles is not affected, so thatthe dispersing and water-reducing effects of the polycarboxylate superplasticizer are not affected.

Owner:GUANGDONG REDWALL NEW MATERIALS

HDPE / FF (High density polyethylene / feather fiber) composite material added with carbonized FF and preparation method thereof

ActiveCN106977787AGuaranteed StrengthImprove toughnessFibre chemical featuresAnimal fibresIsothermal crystallizationNatural fiber

The invention relates to a HDPE / FF (high density polyethylene / feather fiber) composite material added with carbonized FF (feather fiber) and a preparation method thereof, and in particular relates to the surface treatment of regeneration natural fiber, in addition, the natural fiber self is carbonized, and activated by an activator, and the modified natural fiber and a polymer material are compounded by melt blending; the activated modified carbonized FF is added into the high density polyethylene / feather fiber (HDPE / FF) composite material, the modified composite material retains the original excellent properties of the HDPE and the FF, and the toughness of the composite material is well enhanced, the possibility of actual industrial production of the composite material is provided; non-isothermal crystallization kinetics and relaxation behavior are studied, and a theoretical basis is provided for production of protein-like regeneration natural fiber / polymer composite materials.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

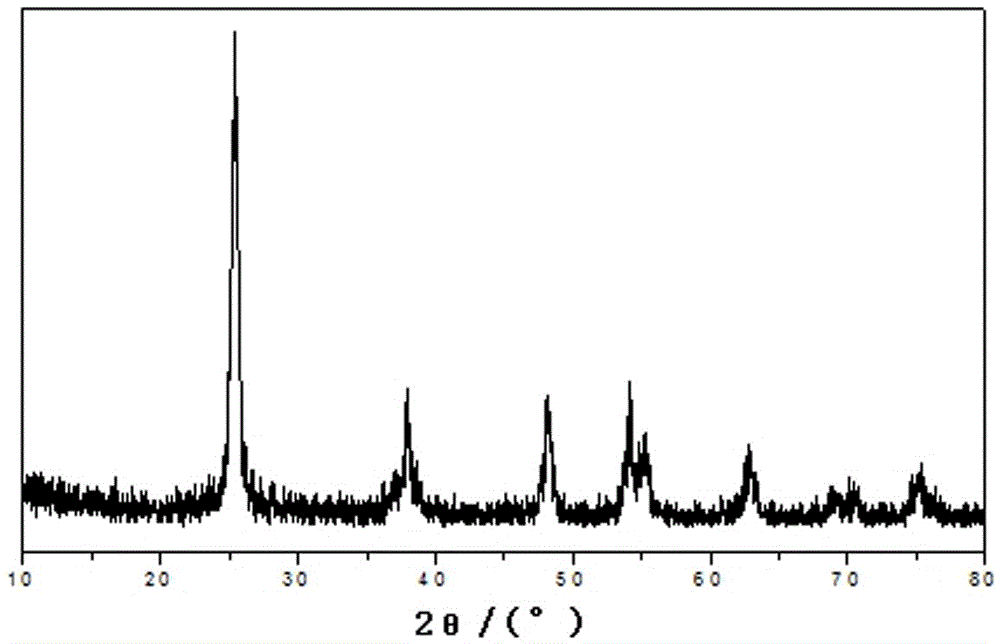

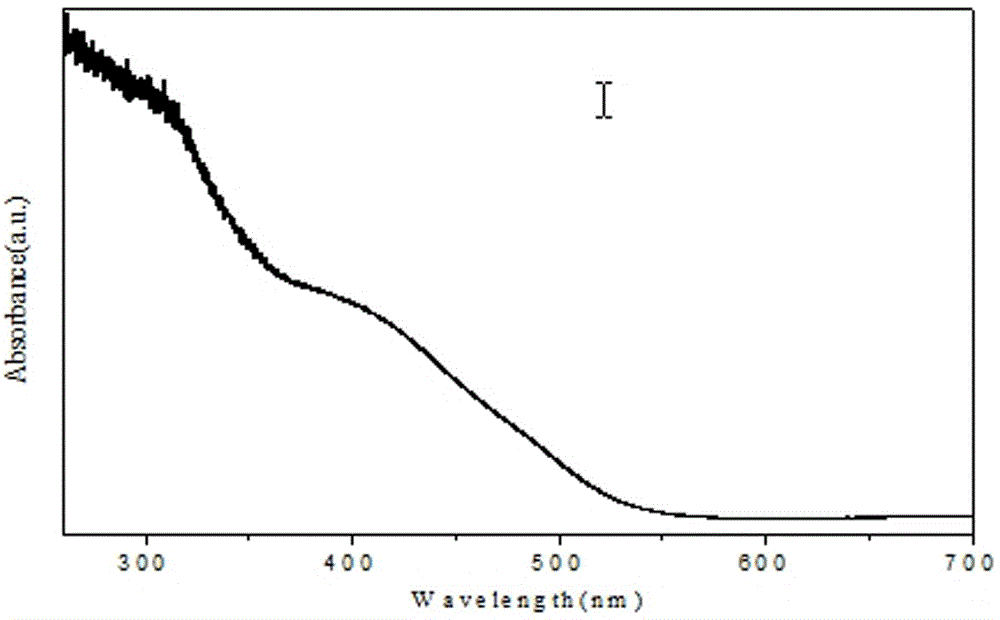

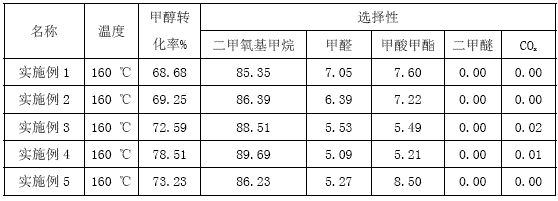

Preparation method of double effect catalyst for high selective oxidation of methane to prepare dimethoxymethane

InactiveCN105536821AGood dispersionEasy to manufacturePhysical/chemical process catalystsOrganic chemistryOxalateSulfate

The invention belongs to the field of solid catalyst for oxidation reactions for preparing dimethoxymethane, and especially relates to a preparation method of a double effect catalyst for high selective oxidation of methane to prepare dimethoxymethane. The preparation method comprises the following steps: (1) weighing oxalic acid and sulfate, adding distilled water containing ethanol, and stirring to dissolve the solid to obtain a solution A; (2) adding ammonium metavanadate into the solution A obtained in the step (1), and stirring to dissolve the solid ammonium metavanadate to obtain a solution B; (3) mixing burned TiO2 with the solution B obtained in the step (2), evenly stirring the solution at a room temperature, and allowing the system to stand still; (4) transferring the product obtained in the step (3) to a reactor, and heating the product; (5) after heating, taking out the product obtained in the step (4) from the reactor, cooling, filtering the white precipitate in the reactor, filtering, drying in vacuum, and burning the powder obtained in the drying step to obtain the target product. The catalyst has the advantages that the V2O5 is well dispersed, and the catalyst has an oxidation activity and acid center.

Owner:BOHAI UNIV

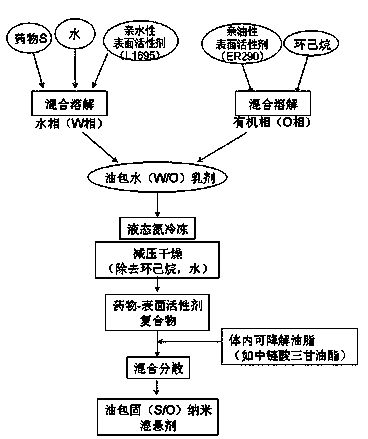

A preparation for improving oral bioavailability of risedronate sodium and a preparing method thereof

InactiveCN103784405AGood dispersionDoes not affect dispersionOrganic active ingredientsPowder deliveryActive agentWater soluble drug

The invention relates to the technical field of medicine, and particularly relates to a suspension that covers a solid medicine with oil (hereinafter referred to as solid-in-oil) and a preparing method thereof, and the suspension is used for improving oral bioavailability of risedronate sodium. The solid-in-oil suspension comprises the medicine, a surfactant and an outer oil phase. The outer oil phase is mixed decanoyl and octanoyl glycerides. The adding weight of the outer oil phase is 70-96.5% of the weight of the solid-in-oil suspension. The adding weight of the surfactant is 1.75-22.5% of the weight of the solid-in-oil suspension. The adding weight of the medicine is 0.5-7.5% of the weight of the solid-in-oil suspension. The dispersity of the water soluble medicine in the oil substrate is improved by preparing a composite of the medicine and the surfactant. A proper oil substrate can be selected according to targeting parts without influences on the dispersity of the medicine in the oil.

Owner:SHENYANG PHARMA UNIVERSITY

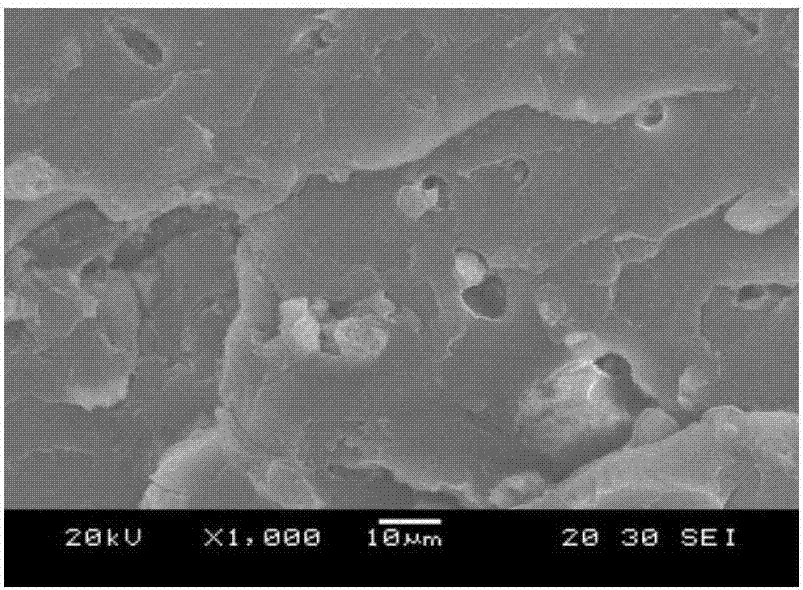

Method for adopting anticorrosion composite urea resin for producing cabinet board

InactiveCN106272831ATake advantage ofSolve insufficient resourcesFlat articlesDomestic articlesWood veneerMonoboard

The invention relates to a home furnishing building material, in particular to a method for adopting anticorrosion composite urea resin for producing a cabinet board. The cabinet board structurally comprises decoration paper, a fir veneer, a chipboard and a back board in sequence from top to bottom. The periphery of the cabinet board is edged with an aluminum alloy. The part between the fir veneer and the chipboard is coated with an anticorrosion composite urea resin adhesive. The part between the chipboard and the back board is coated with an anticorrosion composite urea resin adhesive. An anticorrosion composite urea resin adhesive is also adopted in the chipboard in the cabinet board. The cabinet board manufactured through the method has high water resistance and high bonding strength and is low in formaldehyde residual volume, and meanwhile the anticorrosion function is achieved. The raw material adopted for producing the chipboard in the cabinet board is waste-leftover materials which cannot be used in the process of manufacturing a multilayer eucalyptus board after the eucalyptus board is subjected to rotary cutting, the leftover materials are utilized, wood is saved, and the production cost of an enterprise is reduced.

Owner:南宁市创锦胶合板有限责任公司

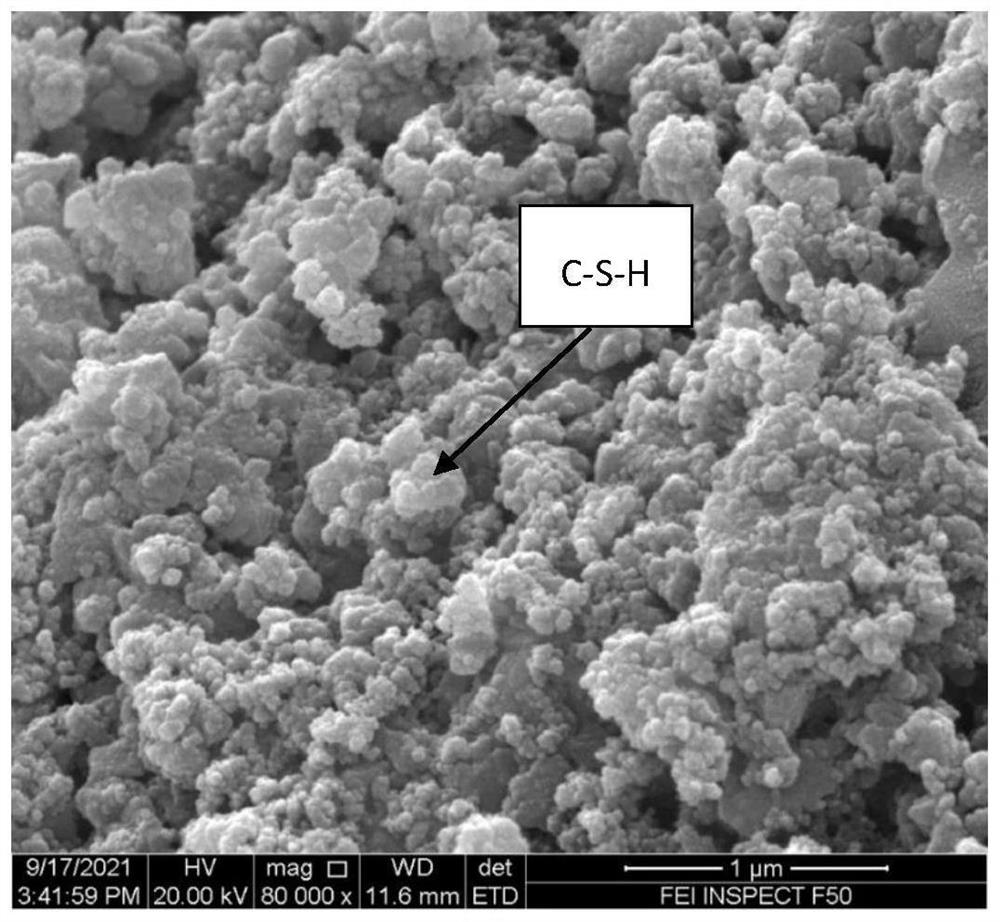

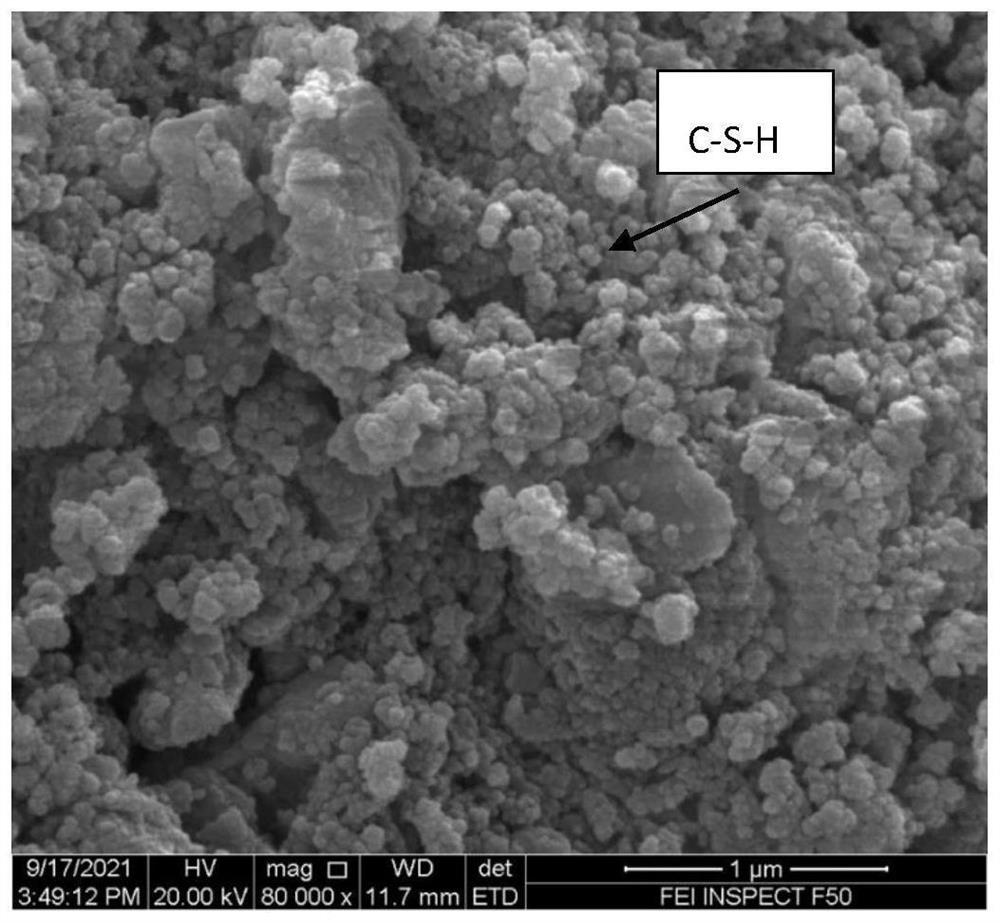

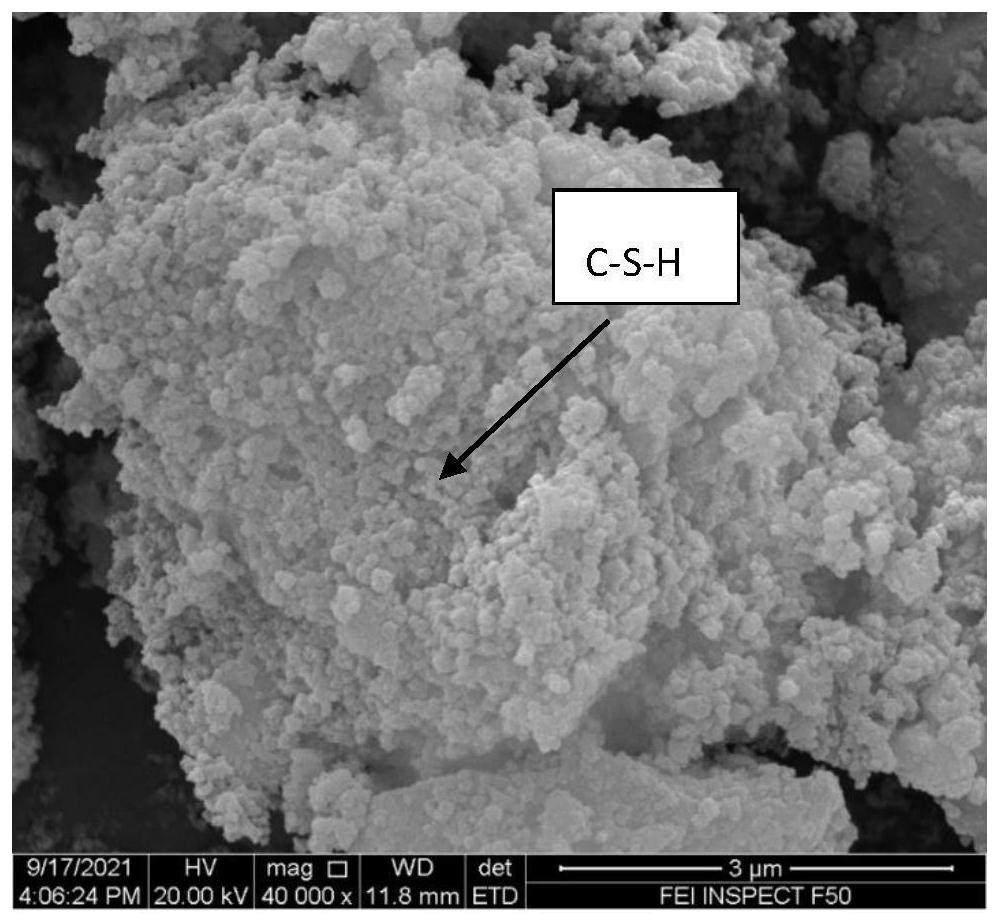

Method for reinforcing cement-based material through steel slag-based in-situ growth of hydrated calcium silicate

ActiveCN114315183ADoes not affect gelling activityDoes not affect dispersionSolid waste managementCement productionCalcium silicateSlag

The invention discloses a method for reinforcing a cement-based material by steel slag-based in-situ growth of hydrated calcium silicate, which comprises the following steps: (1) weighing steel slag powder, a calcium source, a silicon source and a dispersing agent in parts by weight, mixing, and carrying out ball milling to obtain a steel slag dry material; (2) weighing water in parts by weight, adding the dry steel slag into the water, and stirring to obtain steel slag-based in-situ growth hydrated calcium silicate; and (3) adding a cementing material into the steel slag-based in-situ growth hydrated calcium silicate, and stirring to obtain the cement-based material. According to the invention, the steel slag and chemical raw materials are subjected to dry mixing, then calcium silicate hydrate is subjected to in-situ growth through chemical coprecipitation reaction, and finally the cement-based material is prepared by mixing, so that on the premise of not influencing the gelling activity of the steel slag, the in-situ growth of calcium silicate hydrate on a steel slag matrix is realized, the dispersion effect of calcium silicate hydrate is improved, and the agglomeration of calcium silicate hydrate is reduced; the enhanced modification effect on the cement-based material is improved.

Owner:江苏镇江建筑科学研究院集团股份有限公司 +1

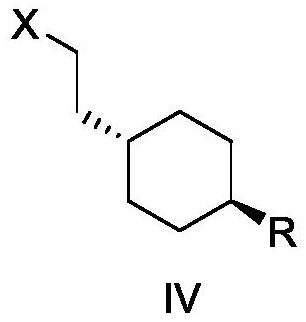

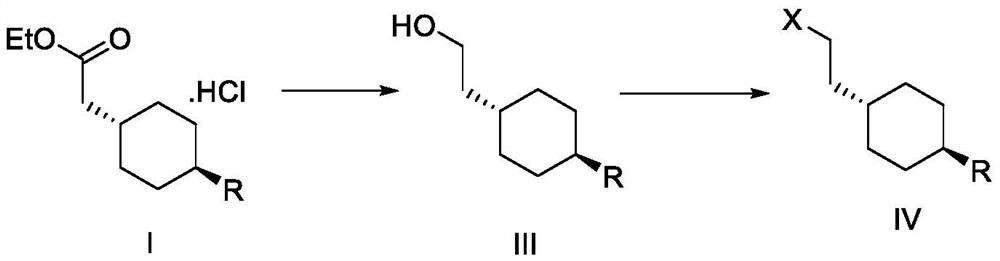

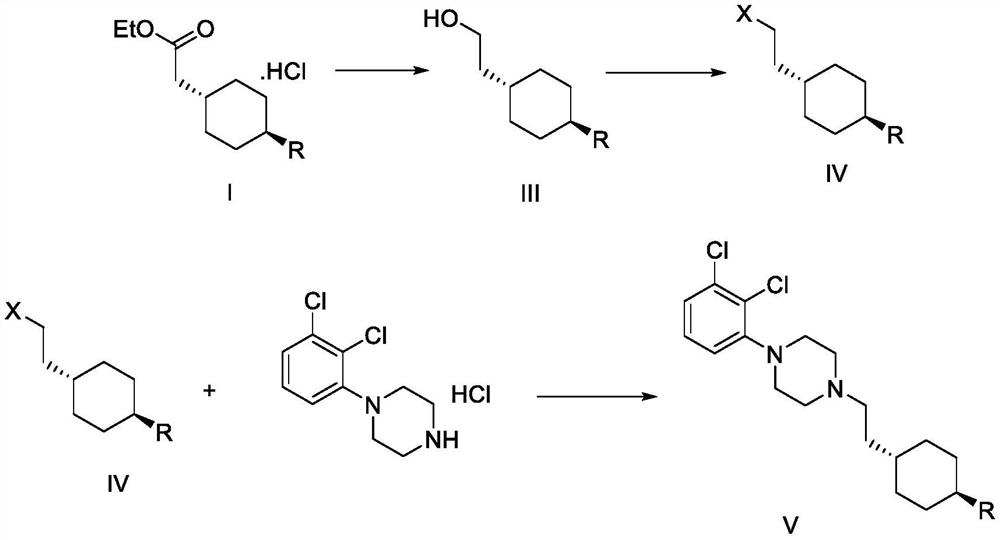

Method for preparing cariprazine and intermediate thereof

PendingCN114262283AReaction raw materials are readily availableEasy to operateCarbamic acid derivatives preparationOrganic compound preparationCariprazineNucleophilic substitution

The invention relates to a method for preparing cariprazine and an intermediate thereof, and the method comprises the following steps: taking trans-4-aminocyclohexane acetate hydrochloride as a starting material, and carrying out Boc protection, reduction, halogenation, nucleophilic substitution, Boc protection removal and amidation reaction to prepare the cariprazine. The alcoholic hydroxyl group of the trans-2-{1-[4-(N-tert-butoxycarbonyl)-amino]-cyclohexyl} ethanol is activated and converted into a group easy to leave, the alcoholic hydroxyl group is creatively converted into the halogen atom, the reaction condition is mild, the yield is high, the raw material medicine which is high in purity and low in impurity content and meets the medicinal requirement can be obtained, and the method is suitable for industrial production.

Owner:SUZHOU VIGONVITA LIFE SCIENCES CO LTD

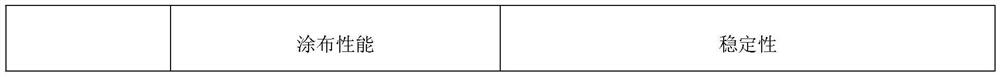

Lithium ion battery negative electrode slurry based on graphene-silicon dioxide composite aerogel and preparation method of lithium ion battery negative electrode slurry

ActiveCN111682206AAvoid reunionIncrease the active siteNegative electrodesSecondary cellsDoped graphenePolystyrene

The invention provides lithium ion battery negative electrode slurry based on graphene-silicon dioxide composite aerogel and a preparation method of the lithium ion battery negative electrode slurry.The preparation method comprises the steps of firstly, taking graphite oxide and 4-methyl-5-glycolic acid-3-allyl thiazole bromide as raw materials; carrying out hydrothermal reaction to obtain nitrogen, sulfur and bromine co-doped graphene oxide; then mixing, hydrolyzing and curing the nitrogen-sulfur-bromine co-doped graphene oxide and tetraethoxysilane to obtain hydrogel; carrying out post-treatment and reduction to obtain graphene-silicon dioxide composite aerogel; and finally, mixing and grinding the graphene-silicon dioxide composite aerogel, a thickening agent, an adhesive, a dispersingagent, a conductive agent, polyvinylidene chloride, sodium polystyrenesulfonate and water to obtain the lithium ion battery negative electrode slurry based on the graphene-silicon dioxide composite aerogel. The coating performance and the stability are obviously improved, the conditions of caking, sedimentation and the like are avoided, and the battery performance is ensured.

Owner:JIANGSU RIYU PHOTOVOTTAIC NEW MATERIAL TECH CO LTD

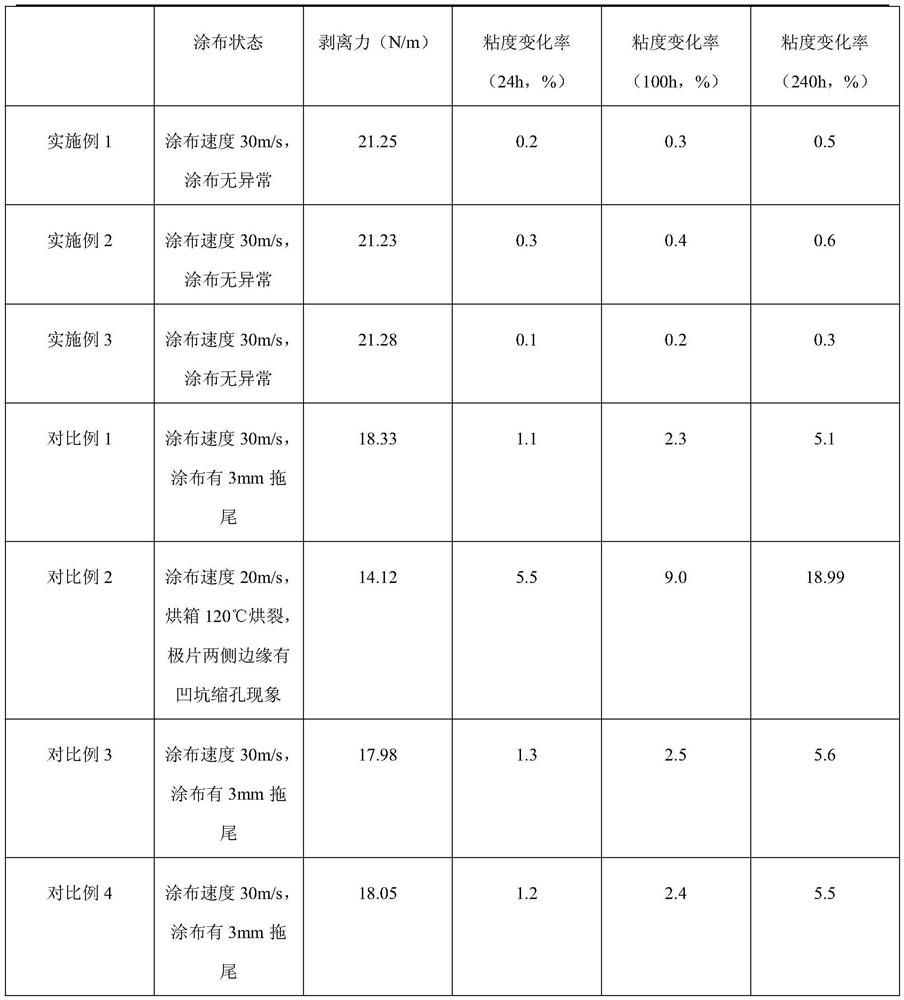

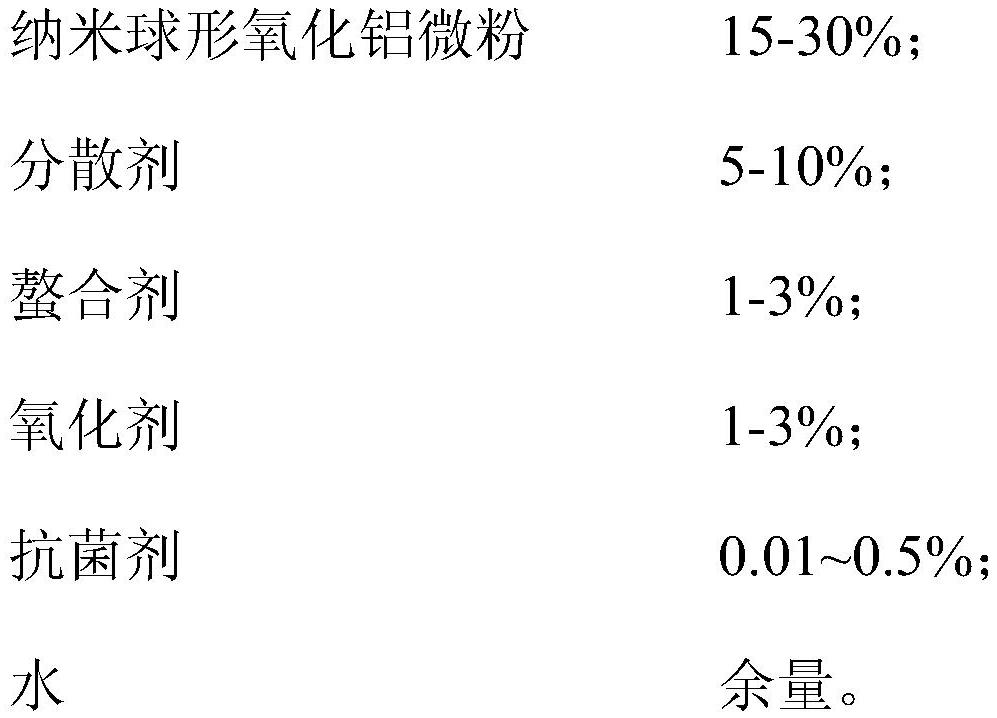

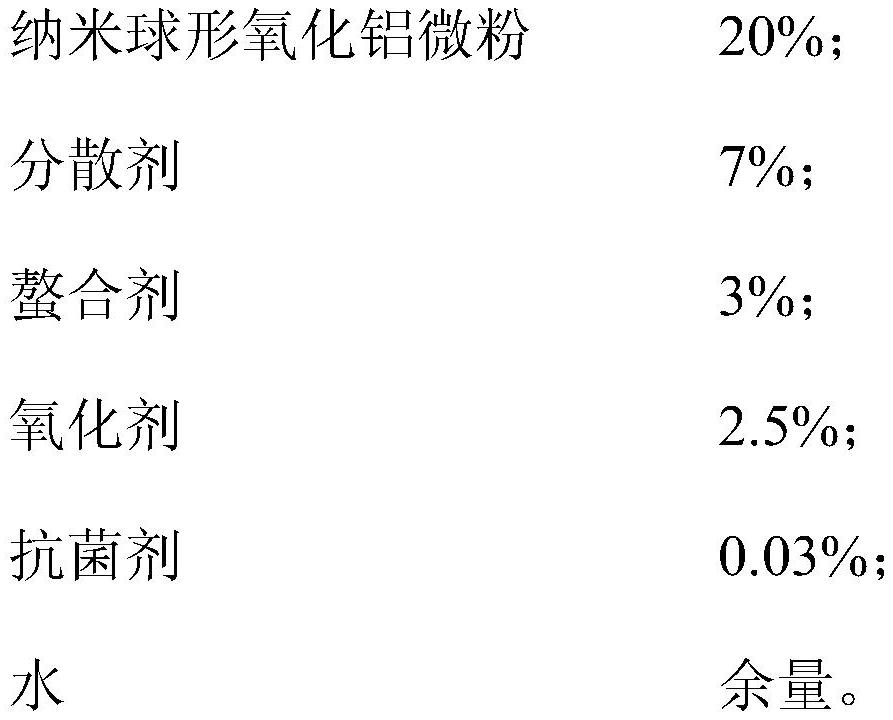

A kind of fine polishing liquid and preparation method thereof

ActiveCN109233644BImprove flatnessImprove polishing efficiencyPolishing compositions with abrasivesMetallurgyNano al2o3

The invention discloses a fine polishing liquid and a preparation method thereof. The fine polishing liquid comprises the following components in weight percent: 10-30% of nano-alumina micropowder, 5-10% of dispersant, 1-5% of chelating agent, Oxidizing agent 0.5-5%, antibacterial agent 0.01-0.5%, water balance. The fine polishing liquid prepared by the invention has good polishing effect, high polishing efficiency, low volatility, harmless to the environment, and high flatness of the workpiece after polishing, and is used for chemical mechanical polishing of semiconductors, especially chemical mechanical polishing in integrated circuits Applications.

Owner:广州亦盛环保科技有限公司

Application of early-strength viscosity-reducing polycarboxylate water reducer in the preparation of prefabricated concrete

The invention provides a kind of concrete, and the invention also provides the application of formula (I) early-strength viscosity-reducing polycarboxylate superplasticizer in the preparation of prefabricated component concrete, using the formula (I) early-strength viscosity-reducing polycarboxylate The prefabricated component concrete produced by carboxylic acid superplasticizer is soft, easy to distribute, and has good slump retention. After the construction is completed, the concrete loses its fluidity instantly, and the initial and final setting are rapid, and the early strength develops quickly. The invention realizes no-steaming curing or no-pressure steaming curing, normal-temperature natural curing production process, shortens mold turnover period, saves energy and protects the environment.

Owner:GUANGDONG REDWALL NEW MATERIALS

An early-strength viscosity-reducing polycarboxylate water reducer containing three viscosity-reducing functional groups and its preparation method

The invention provides an early-strength viscosity-reducing polycarboxylate water-reducer. The early-strength viscosity-reducing polycarboxylate water-reducer synthesized by the present invention has synergistic effects between components and functional groups, which is different from that of the prior art. Compared with the synthetic viscosity-reducing polycarboxylate superplasticizer, the viscosity-reducing effect is superior and the water-reducing rate is not affected. At the same time, due to the introduction of a large number of hydrophobic alkyl, phenyl and ester groups in the PEG side chain, the HLB value, enhanced surface active effect, has good shrinkage reduction performance. The water reducing agent of the present invention has a good effect of promoting cement hydration and improving the early strength development of concrete; the water reducing agent of the present invention has early strength and hydrophobic viscosity-reducing functional groups located on the side chain, and can adjust the content of viscosity-reducing and early-strength functional groups. Adjust the early strength and viscosity reduction effect of the superplasticizer, but it does not affect the dispersion effect of the dispersing group on the cement particles, so it does not affect the dispersion and water reduction effect of the superplasticizer.

Owner:GUANGDONG REDWALL NEW MATERIALS

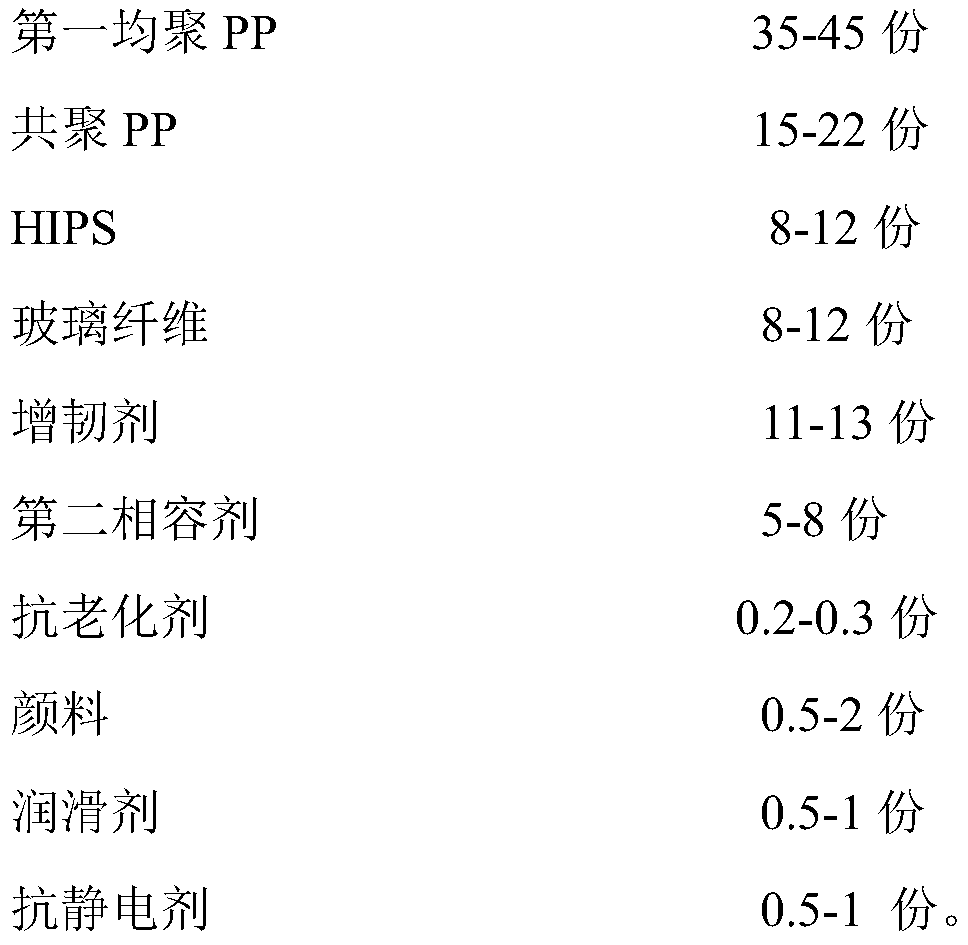

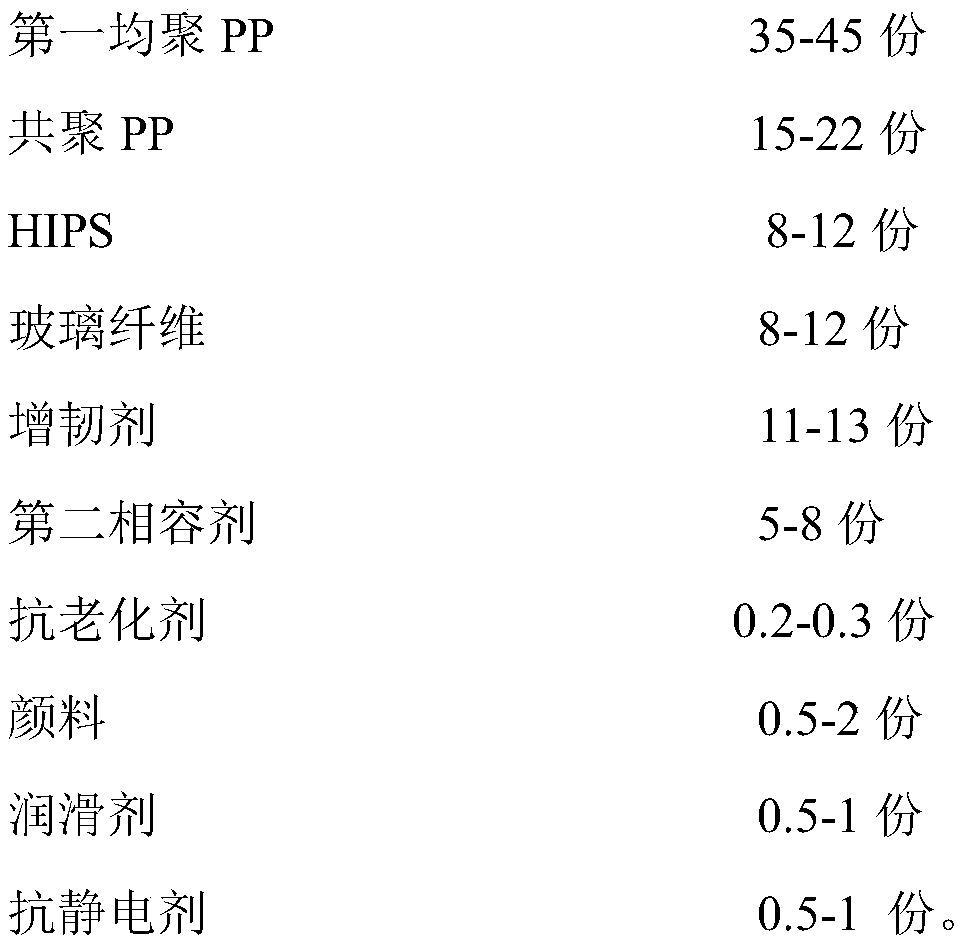

Military ammunition can material and preparation method thereof

The invention provides a military ammunition can material and a preparation method thereof. The military ammunition can material is formed by mixing a long glass fiber composite material and a short glass fiber composite material. The long glass fiber composite material is prepared by the following raw materials, by weight: 30-40 parts of first homopolymerization PP, 50-60 parts of glass fibers, and 8-12 parts of a first compatilizer. The short glass fiber composite material is prepared by the following raw materials, by weight: 35-45 parts of first homopolymerization PP, 15-22 parts of copolymerization PP, 8-12 parts of HIPS, 8-12 parts of glass fibers, 11-13 parts of a toughening agent, 5-8 parts of a second compatilizer, 0.2-0.3 part of an anti-aging agent, 0.5-2 parts of a pigment, 0.5-1 part of a lubricant, and 0.5-1 part of an antistatic agent. A composite material with excellent comprehensive mechanical properties and corrosion resistance, aging resistance, cold resistance and antistatic properties which can meet requirements of military ammunition cans is obtained by mixing the long glass fiber composite material and the short glass fiber composite material.

Owner:LUOYANG CITY HEZHIYANG MACROMOLECULE MATERIAL

A viscosity-reducing polycarboxylate water-reducer containing three viscosity-reducing functional groups, its preparation method and application

The invention provides a viscosity-reducing active macromonomer, and the invention also provides a viscosity-reducing polycarboxylate water-reducer. The viscosity-reducing polycarboxylate water-reducer synthesized by the invention has a The functional groups cooperate with each other, and compared with the viscosity-reducing polycarboxylate superplasticizer synthesized in the prior art, the viscosity-reducing effect is superior and the water-reducing rate is not affected. At the same time, due to the introduction of a large number of hydrophobic alkyl groups, ester groups and phenyl groups in the PEG side chain, the HLB value is effectively reduced, the surface activity effect is enhanced, and the shrinkage effect is good. The concrete added with the product of the present invention has a shrinkage Low rate, no cracking. The viscosity-reducing hydrophobic functional group is located on the side chain, and the viscosity-reducing effect of the water reducer can be adjusted through the content of the viscosity-reducing functional group, but it does not affect the content of the dispersing group and the dispersion effect on cement particles, so it does not affect the water reducing effect. agent dispersion and water-reducing effect.

Owner:河北红墙新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com