A kind of fine polishing liquid and preparation method thereof

A fine polishing and nano technology, applied in the field of polishing liquid, can solve the problems of improving polishing effect, unfavorable environmental protection, inapplicability, etc., and achieve the effect of high flatness, short production cycle and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

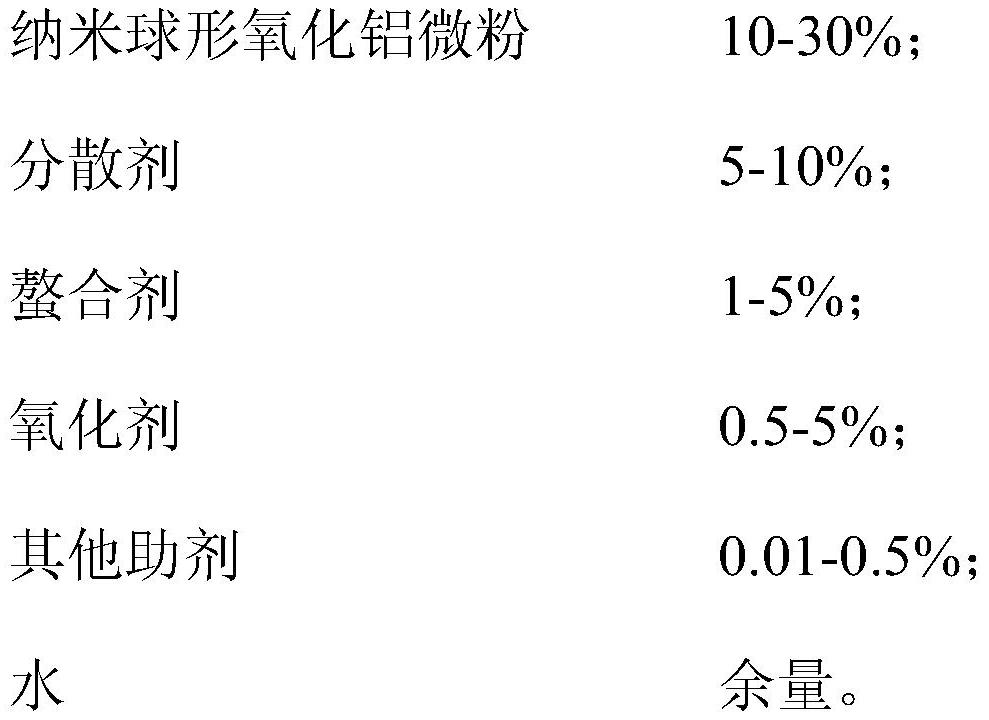

[0046] The present embodiment provides a kind of fine polishing liquid, comprises the component of following percentage by weight:

[0047]

[0048] Wherein the particle size of the nano-spherical aluminum oxide micropowder is 100nm, the dispersant is a naphthalene sulfonate polymer, the molecular weight of the naphthalene sulfonate polymer is 4000, and the chelating agent is hydroxyethylethylenediamine and dihydroxyglutaric acid The combination, the mass ratio of hydroxyethylethylenediamine and dihydroxyglutarate is 0.8:1, the oxidizing agent is sodium thiosulfate, and the antibacterial agent is methylisothiazolone.

[0049] The preparation method of described polishing liquid is:

[0050] (1) Mix the nano-alumina micropowder, the dispersant and water, stir and dissolve to obtain the first mixture;

[0051] (2) Add a chelating agent, an oxidizing agent and other auxiliary agents to the first mixture prepared in step (1), stir and dissolve to obtain the fine polishing liquid...

Embodiment 2

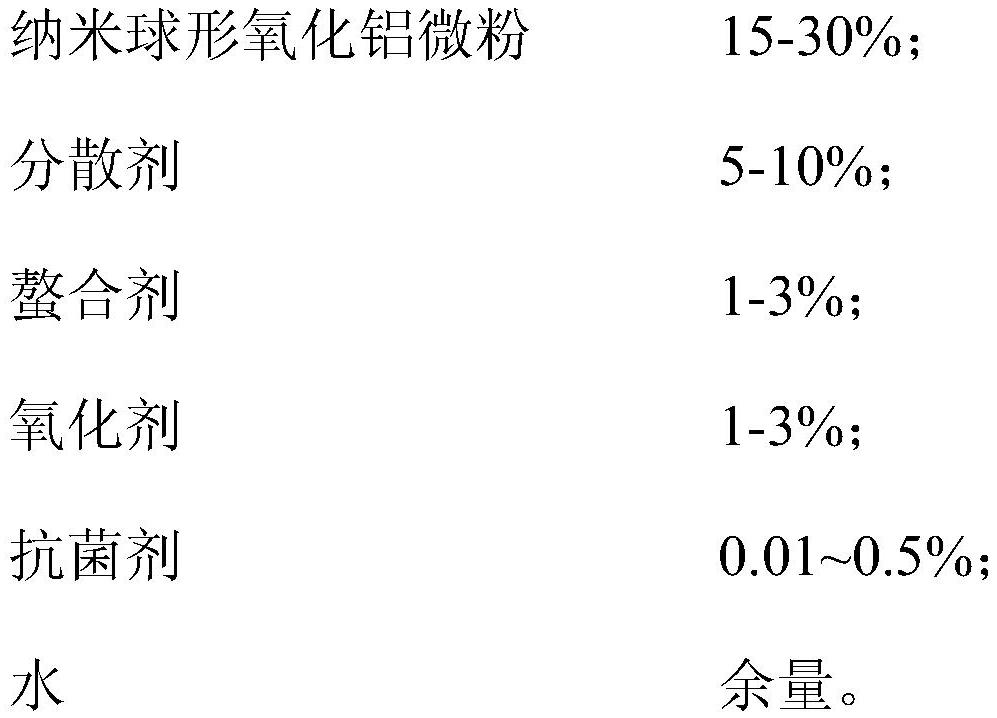

[0053] The present embodiment provides a kind of fine polishing liquid, comprises the component of following percentage by weight:

[0054]

[0055] Wherein the particle size of the nano-spherical alumina micropowder is 80nm, the dispersant is a naphthalenesulfonate polymer, the molecular weight of the naphthalenesulfonate polymer is 3000, and the chelating agent is hydroxyethylethylenediamine and dihydroxyglutarate The combination, the mass ratio of hydroxyethylethylenediamine and dihydroxyglutarate is 1:1, the oxidizing agent is sodium thiosulfate, and the antibacterial agent is methylisothiazolone.

[0056] The preparation method of described polishing liquid is:

[0057] (1) Mix the nano-alumina micropowder, the dispersant and water, stir and dissolve to obtain the first mixture;

[0058] (2) Add a chelating agent, an oxidizing agent and other auxiliary agents to the first mixture prepared in step (1), stir and dissolve to obtain the fine polishing liquid.

Embodiment 3

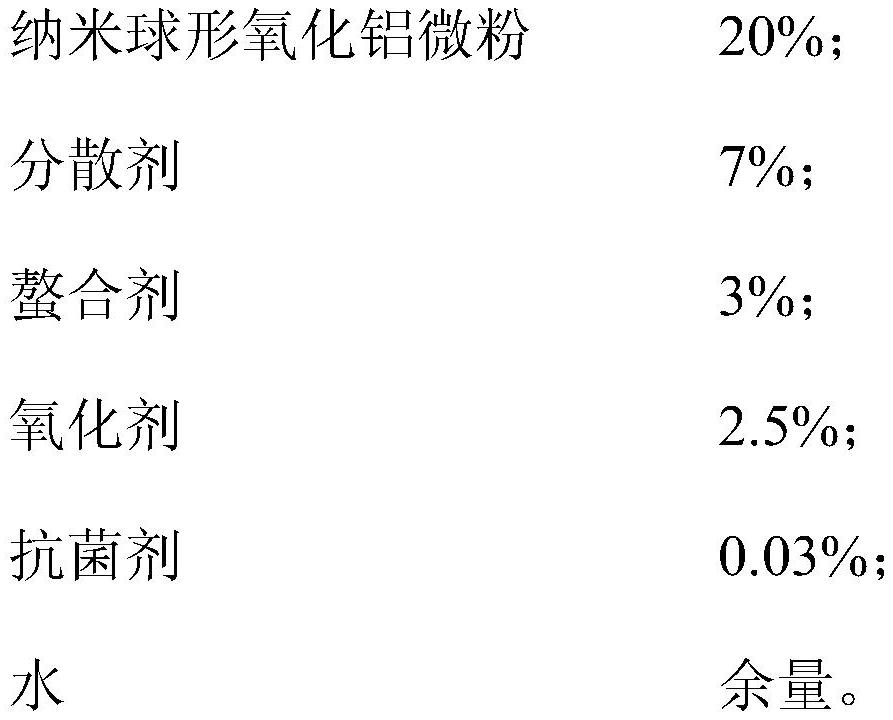

[0060] The present embodiment provides a kind of fine polishing liquid, comprises the component of following percentage by weight:

[0061]

[0062] Wherein the particle size of the nano-spherical aluminum oxide micropowder is 100nm, the dispersant is a naphthalene sulfonate polymer, the molecular weight of the naphthalene sulfonate polymer is 4800, and the chelating agent is hydroxyethylethylenediamine and dihydroxyglutaric acid The combination, the mass ratio of hydroxyethylethylenediamine and dihydroxyglutarate is 0.5:1, the oxidizing agent is sodium thiosulfate, and the antibacterial agent is methylisothiazolone.

[0063] The preparation method of described polishing liquid is:

[0064] (1) Mix the nano-alumina micropowder, the dispersant and water, stir and dissolve to obtain the first mixture;

[0065] (2) Add a chelating agent, an oxidizing agent and other auxiliary agents to the first mixture prepared in step (1), stir and dissolve to obtain the fine polishing liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com