Digital printing method for active ink and multi-component fiber fabric

A technology of reactive ink and reactive yellow, which is applied in the fields of ink, dyeing, textiles and papermaking, etc., can solve the problem of fabric hand feeling and color fastness to rubbing color fastness that are difficult to meet customer requirements, color brightness is not high enough, fineness is not high Advanced problems, to achieve the effect of reducing the difficulty of sewage treatment and sewage discharge, reducing the nitrogen content of sewage and washing times, high color yield and fineness

Inactive Publication Date: 2019-11-12

CHINA TEXTILE ACAD JIANGNAN BRANCH

View PDF8 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] (1) Pigment digital printing is used to adhere to the fabric by adhesives, and there is no requirement for the composition of the fabric, but the feel and color fastness of the pigment printed fabric, especially the color fastness to rubbing, are difficult to meet the customer's requirements, and the color is bright degree is not high enough;

[0005] (2) Only digitally print the components with the most content in polyester / cellulose fabrics. The printing pattern is relatively fuzzy and the fineness is not high, and the color is not uniform and not bright, especially when the content of polyester and cellulose fibers is 50%. around time

Secondly, the vat dye blue RSN and the disperse dye yellow RGFL are mixed to make a digital printing ink. The ratio of the two dyes in the ink cannot be changed after being fixed, and the depth can only be changed at the same time when printing; when the ratio of polyester and cotton in the fabric has Cannot print the same color when changing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

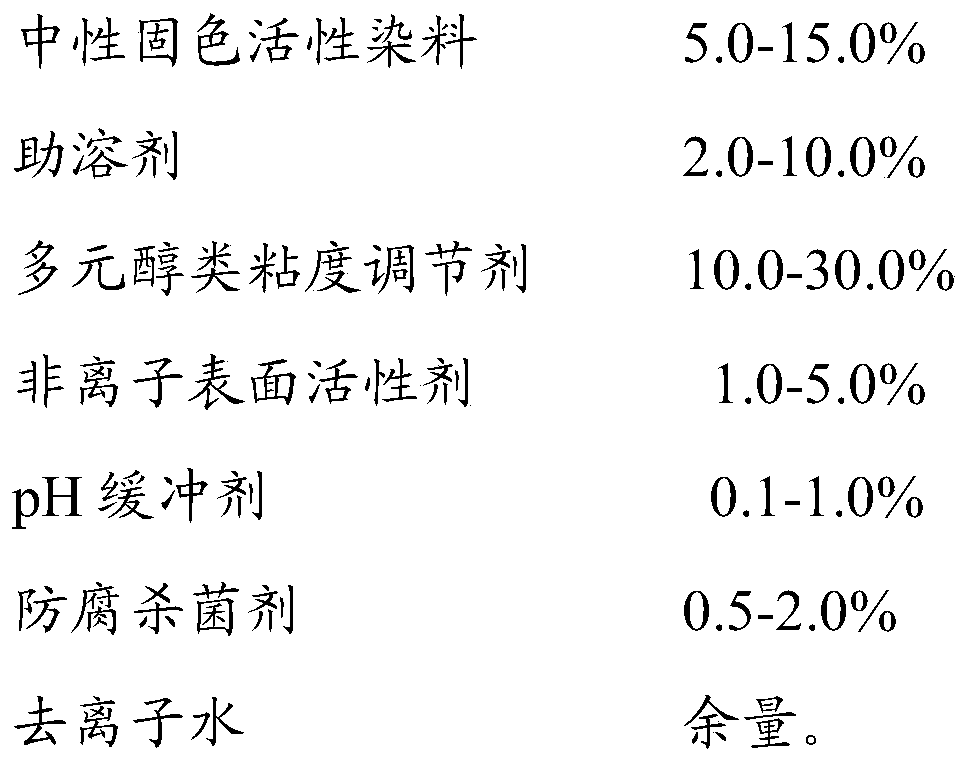

[0038] Embodiment 1: reactive ink

[0039]

Embodiment 2

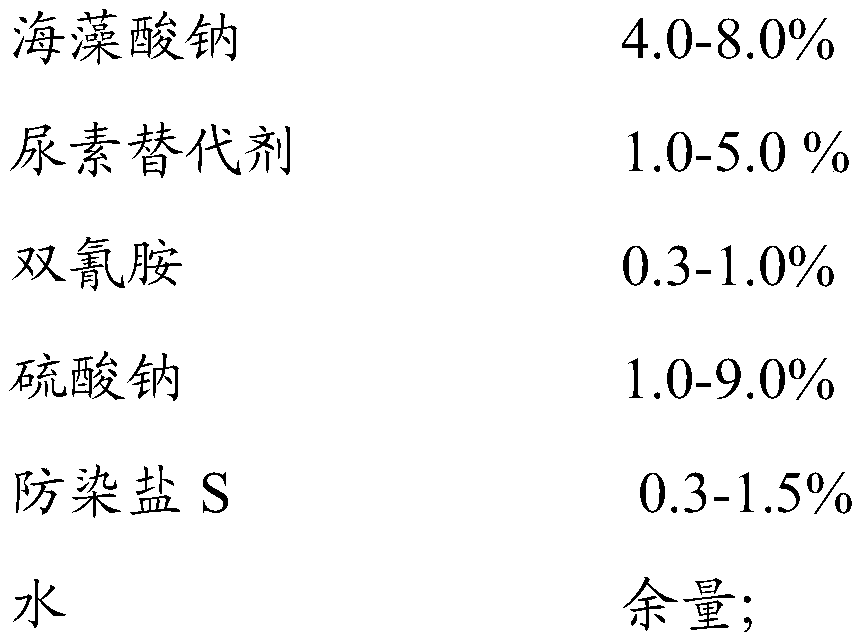

[0040]Embodiment 2: active ink

[0041]

Embodiment 3

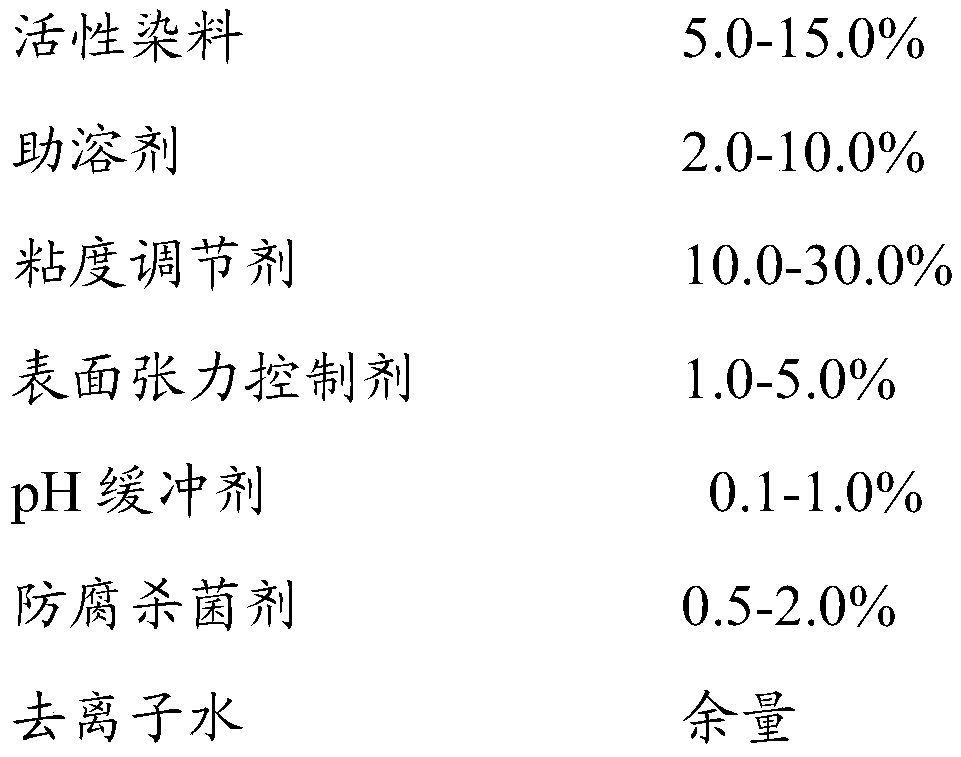

[0042] Embodiment 3: active ink

[0043]

[0044]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a digital printing method for an active ink and a multi-component fiber fabric and belongs to the technical field of dyeing and printing of fabrics. The active ink comprises an active dye, a cosolvent, a viscosity adjusting agent, a surface tension control agent, a pH value buffer agent, an anti-corrosion sterilization agent and deionized water. The ink is adopted for digital printing on polyester / cellulose multi-component fiber fabrics of different ratios, polyesters and cellulose fibers can be subjected to jet printing of any color, the polyesters and the cellulose fibers are slightly contaminated, and the color fastness, the color yield and the fineness of printed patters are all high.

Description

technical field [0001] The application relates to a new type of active ink and a digital printing method of polyester / cellulose multi-component fiber fabric using the active ink, which belongs to the technical field of textile dyeing or printing. Background technique [0002] Multi-component fiber fabrics combine the performance advantages of various fibers, and become the focus of fabric development and market attention, and are increasingly favored by consumers, especially polyester / cellulose fabrics, of which polyester mainly includes PET, PBT, PTT, and cellulose fibers include cotton, hemp, viscose, Lyocell, etc., which can combine the advantages of various polyester fibers and cellulose fibers. [0003] Digital printing breaks the limitation of the number of sets and flower length of traditional printing, and has become one of the development directions of the printing and dyeing industry in the future with the characteristics of no need for plate making, fast response,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D11/328C09D11/30C09D11/38D06P1/16D06P1/38D06P1/44D06P1/48D06P1/642D06P1/649D06P1/673D06P3/872D06P5/10D06P5/30

CPCC09D11/30C09D11/328C09D11/38D06P1/16D06P1/38D06P1/445D06P1/48D06P1/6426D06P1/6494D06P1/6735D06P3/8252D06P5/10D06P5/30

Inventor 李俊玲曹晨笑许增慧吕水君

Owner CHINA TEXTILE ACAD JIANGNAN BRANCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com