HDPE / FF (High density polyethylene / feather fiber) composite material added with carbonized FF and preparation method thereof

A composite material and carbonization technology, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, fiber treatment, etc., can solve the problems of weak interfacial bonding, difficulty in uniform dispersion, natural fiber and resin affecting toughening effect, etc., to improve toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

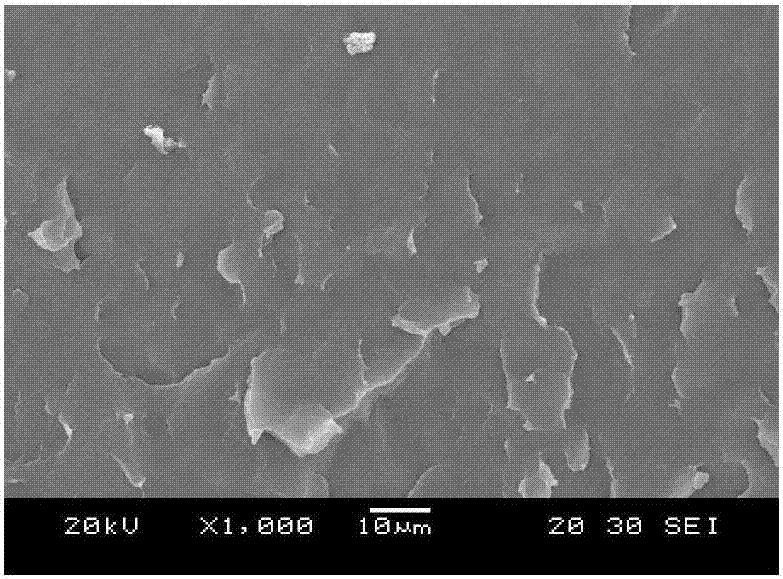

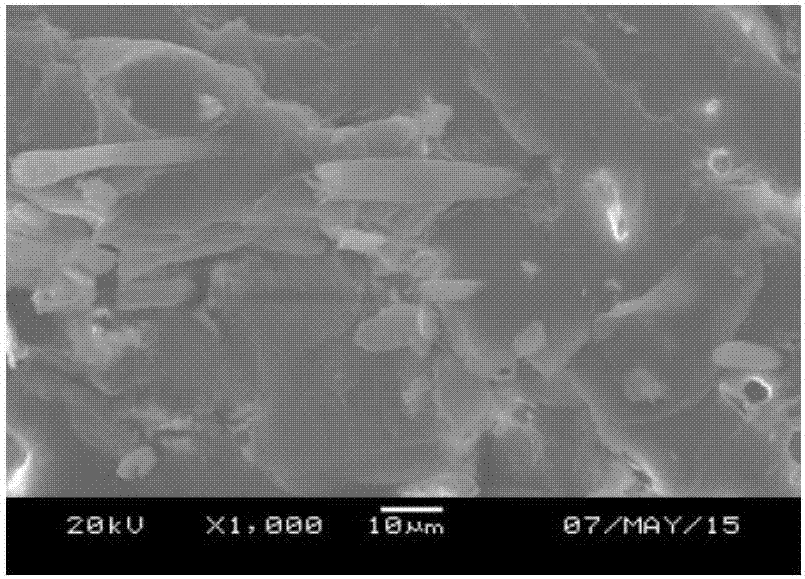

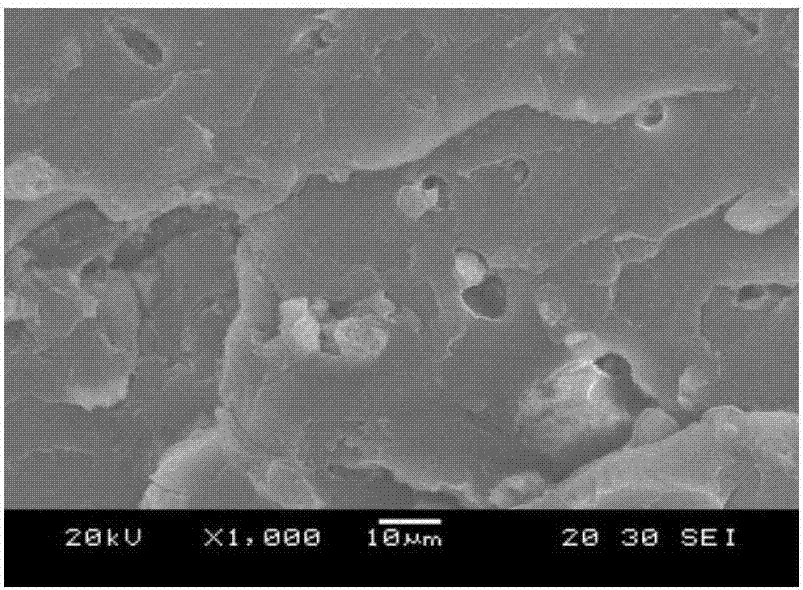

Image

Examples

Embodiment 1

[0059] A kind of HDPE / FF composite material that adds carbonized FF, its formula is:

[0060]

[0061] A kind of preparation method of adding the HDPE / FF composite material of charred FF, the step of its preparation method is:

[0062] (1) Prepare 90wt% ethanol aqueous solution, pour KH570 into the ethanol solution, stir magnetically for 1 hour, and vibrate ultrasonically for 2 hours. Soak FF in ethanol for 1 hour, heat in a water bath at 60-80°C and stir constantly, add the treated KH570 solution drop by drop into the ethanol slurry containing FF, stir for 2 hours, take out the FF in the slurry, Dry in an oven at °C for later use.

[0063] (2) Heat 20g FF in a muffle furnace for 26 hours at a temperature of 215°C; sinter the heated carbonized FF in a muffle furnace for 2 hours at a temperature of 400°C; heat the carbonized FF in a microwave oven for 2 hours, and adjust the temperature for the fire. Soak carbonized FF in 25% citric acid solution, soak for 24 hours, heat ...

Embodiment 2

[0067] A kind of HDPE / FF composite material that adds carbonized FF, its formula is:

[0068]

[0069] A kind of preparation method of adding the HDPE / FF composite material of charred FF, the step of its preparation method is:

[0070] (1) Prepare 90wt% ethanol aqueous solution, pour DL-411A into the ethanol solution, stir magnetically for 1 hour, and vibrate ultrasonically for 2 hours. Soak FF in ethanol for 1 h, add the treated DL-411A solution drop by drop into the ethanol slurry containing FF, stir for 2 h, take out the FF in the slurry, and dry it in an oven at 70°C for later use.

[0071] (2) Heat 20g FF in a muffle furnace for 26 hours at a temperature of 215°C; sinter the heated carbonized FF in a muffle furnace for 2 hours at a temperature of 400°C; heat the carbonized FF in a microwave oven for 2 hours, and adjust the temperature for the fire. Soak the carbonized FF in a citric acid solution with a concentration of 10-30%. After soaking for 24 hours, heat it wit...

Embodiment 3

[0075] A kind of HDPE / FF composite material that adds carbonized FF, its formula is:

[0076]

[0077] A kind of preparation method of adding the HDPE / FF composite material of charred FF, the step of its preparation method is:

[0078] (1) Prepare 90wt% ethanol aqueous solution, pour NDZ-201 into the ethanol solution, stir magnetically for 1 hour, and vibrate ultrasonically for 2 hours. Soak FF in ethanol for 1 h, add the treated NDZ-201 solution drop by drop into the ethanol slurry containing FF, stir for 2 h, take out the FF in the slurry, and dry it in an oven at 70°C for later use.

[0079] (2) Heat 20g FF in a muffle furnace for 26 hours at a temperature of 215°C; sinter the heated carbonized FF in a muffle furnace for 2 hours at a temperature of 400°C; heat the carbonized FF in a microwave oven for 2 hours, and adjust the temperature for the fire. Soak the carbonized FF in a citric acid solution with a concentration of 10-30%. After soaking for 24 hours, heat it wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com