Method for reinforcing cement-based material through steel slag-based in-situ growth of hydrated calcium silicate

A technology of calcium silicate hydrate and in-situ growth, which is applied in the field of building material reinforcement, can solve the problems of poor effect of modification and reinforcement of cement-based materials, difficulty in dispersing nanometer calcium silicate hydrate, and reducing the cementing activity of steel slag, etc. Achieve the effect of promoting strength development, enhancing and enhancing modification effect, and fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

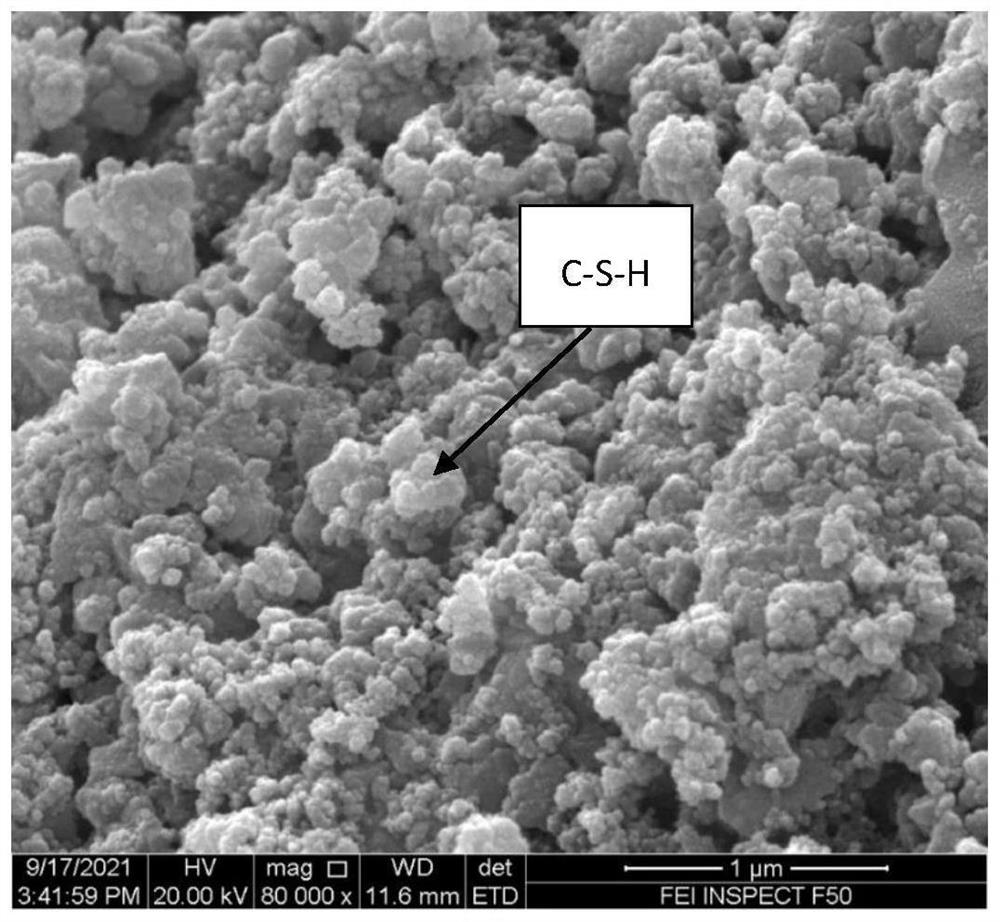

[0030] A method for in-situ growth of steel slag-based calcium silicate hydrate reinforced cement-based materials, comprising the following steps:

[0031] (1) Mixing: According to the number of parts by mass, weigh 100 parts of steel slag powder with a particle size of less than 75 μm, 3.52 parts of calcium acetate monohydrate, 4.24 parts of sodium metasilicate pentahydrate and 2 parts of polycarboxylate superplasticizer. It is mixed evenly in a mixer, and then placed in a ball mill at a speed of 150 rpm for 10 minutes to obtain dry steel slag;

[0032] (2) Chemical co-precipitation reaction: Weigh 400 parts of water in parts by mass and place it in the stirring pot, add the dry steel slag material obtained in step (1) into it while stirring, and stir for 10 minutes to obtain the steel slag-based in-situ growth hydration calcium silicate;

[0033] (3) Stirring: Stir the steel slag base obtained in the step (2) to grow calcium silicate hydrate in situ, add 900 parts of P.II52...

Embodiment 2

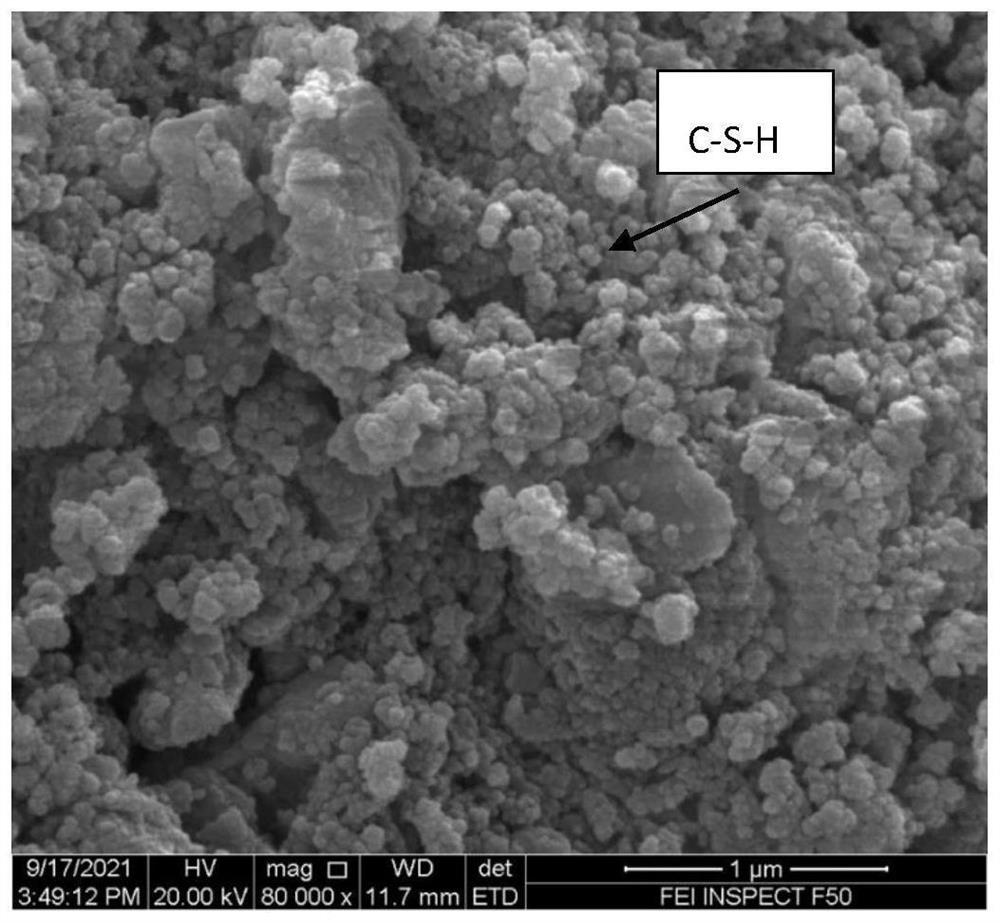

[0035] A method for in-situ growth of steel slag-based calcium silicate hydrate reinforced cement-based materials, comprising the following steps:

[0036] (1) Mixing: According to the number of parts by mass, weigh 100 parts of steel slag powder with a particle size of less than 75 μm, 7.05 parts of calcium acetate monohydrate, 8.48 parts of sodium metasilicate pentahydrate and 2 parts of polycarboxylate high-efficiency water reducer. It is mixed evenly in a mixer, and then placed in a ball mill at a speed of 250 rpm for 30 minutes to obtain dry steel slag;

[0037] (2) Chemical co-precipitation reaction: Weigh 400 parts of water in parts by mass and place it in the stirring pot, add the dry steel slag material obtained in step (1) into it while stirring, and stir for 10 minutes to obtain the steel slag-based in-situ growth hydration calcium silicate;

[0038] (3) Stirring: Stir the steel slag base obtained in the step (2) to grow calcium silicate hydrate in situ, add 900 pa...

Embodiment 3

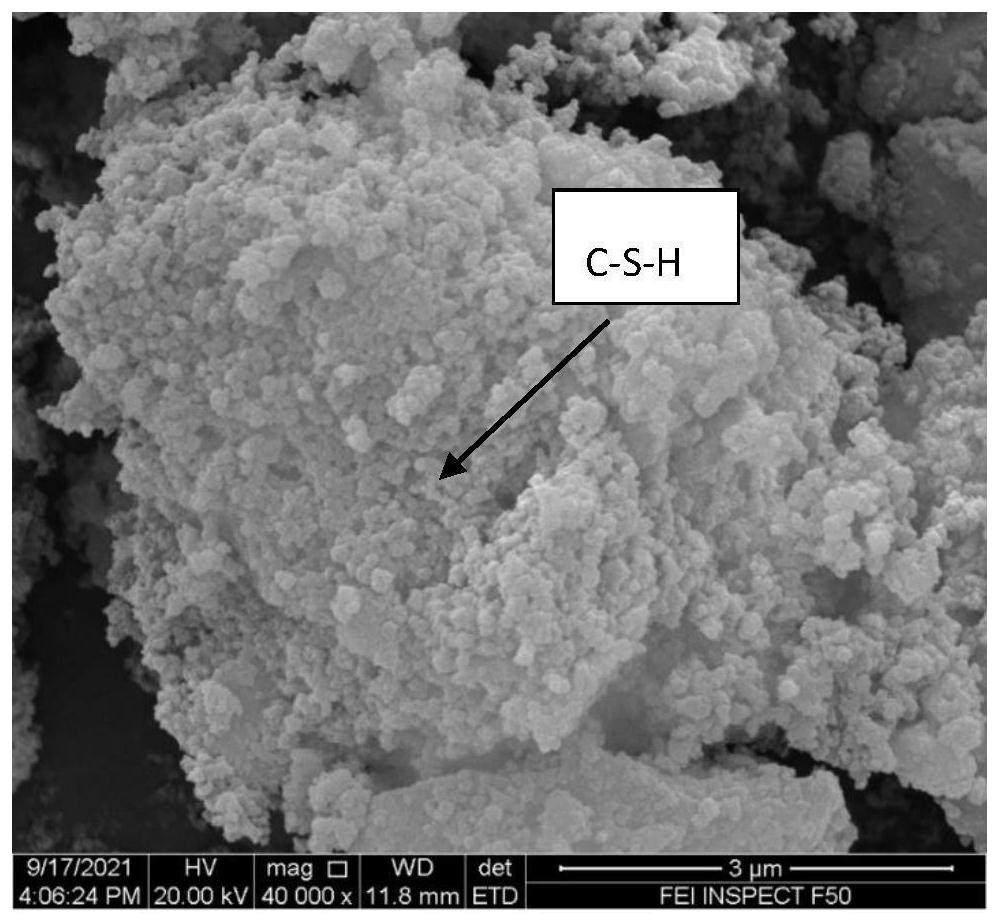

[0040] A method for in-situ growth of steel slag-based calcium silicate hydrate reinforced cement-based materials, comprising the following steps:

[0041] (1) Mixing: by mass parts, weigh 100 parts of steel slag powder with a particle size less than 75 μm, 10.56 parts of calcium acetate monohydrate, 12.72 parts of sodium metasilicate pentahydrate and 2 parts of polycarboxylate superplasticizer. It is mixed evenly in a mixer, and then placed in a ball mill at a speed of 200 rpm for 20 minutes to obtain dry steel slag;

[0042](2) Chemical co-precipitation reaction: Weigh 400 parts of water in parts by mass and place it in the stirring pot, add the dry steel slag material obtained in step (1) into it while stirring, and stir for 20 minutes to obtain the steel slag-based in-situ growth hydration calcium silicate;

[0043] (3) Stirring: Stir the steel slag base obtained in the step (2) to grow calcium silicate hydrate in situ, add 900 parts of P.II52.5 Portland cement to it, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com