Preparation method of double effect catalyst for high selective oxidation of methane to prepare dimethoxymethane

A dimethoxymethane, high-selectivity technology, applied in the preparation of organic compounds, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of catalyst reactivity and selectivity reduction, acid center easy loss of catalytic activity , selectivity reduction and other issues, to achieve the effect of stable activity, not easy to lose, and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

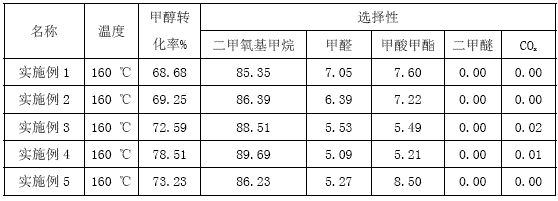

Embodiment 1

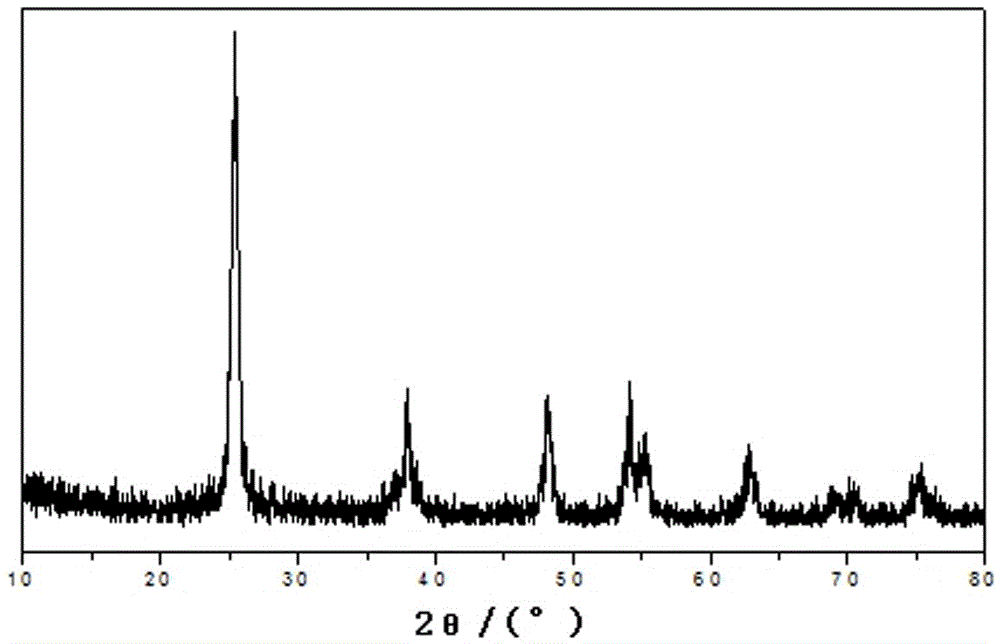

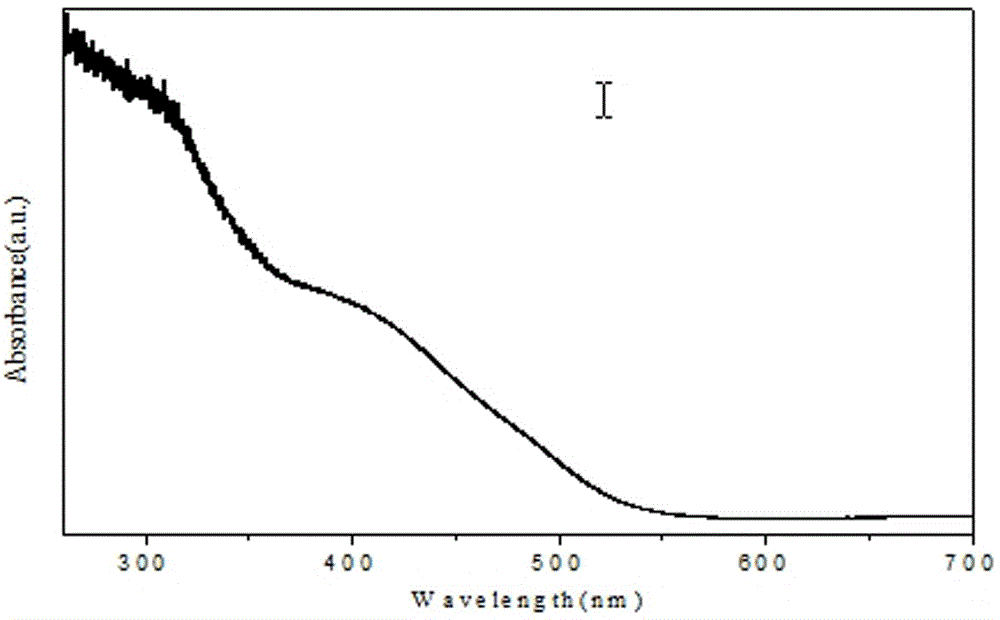

[0026] Weigh 1g oxalic acid H 2 C 2 o 4 2H 2 O solid and 1 g potassium sulfate K 2 SO 4 , dissolved in 20g ethanol-distilled water solution, the mass concentration of ethanol in distilled water is 5%, after stirring to dissolve the solid, add 0.5g ammonium metavanadate NH 4 VO 3 , stirring to make NH 4 VO 3 Completely dissolved, the resulting solution was mixed with 10g of calcined TiO 2 The powders were mixed, stirred evenly at room temperature, and then allowed to stand for 1 hour, then transferred to a reactor with a polytetrafluoroethylene substrate and treated at 80°C for 12 hours. After the treatment, take out the reaction kettle, cool it in the air naturally, filter the precipitate in the reaction kettle, wash it with ethanol for 3 times, then wash it with water for 3 times, and then dry it in vacuum at 40°C for 18 hours to obtain a powder; put the dried powder at 400°C Under roasting for 8h, SO 4 2- Modified TiO 2 load V 2 o 5 solid catalyst.

Embodiment 2

[0028] Weigh 1g oxalic acid H 2 C 2 o 4 2H 2 O solid and 2.5 g sodium sulfate Na 2 SO 4 , dissolved in 10g ethanol-distilled water solution, the mass concentration of ethanol in distilled water is 25%, after stirring to dissolve the solid, add 1g ammonium metavanadate NH 4 VO 3 , stirring to make NH 4 VO 3 Completely dissolved, the resulting solution was mixed with 4g of calcined TiO 2 The powders were mixed, stirred evenly at room temperature, and then allowed to stand for 12 hours, then transferred to a reactor with a PTFE substrate and treated at 140°C for 4 hours. After the treatment, take out the reaction kettle, cool it naturally in the air, filter the precipitate in the reaction kettle, wash with ethanol for 3 times, then wash with water for 3 times, then vacuum dry at 80°C for 4 hours to obtain a powder; dry the obtained powder at 600°C Roasted for 3h to get SO 4 2- Modified TiO 2 load V 2 o 5 solid catalyst.

Embodiment 3

[0030] Weigh 0.3g oxalic acid H 2 C 2 o 4 2H 2 O solid and 2.5 g magnesium sulfate MgSO 4 , dissolved in 5g ethanol-distilled water solution, the mass concentration of ethanol in distilled water is 45%, after stirring to dissolve the solid, add 0.25g ammonium metavanadate NH 4 VO 3 , stirring to make NH 4 VO 3 Completely dissolved, the resulting solution was mixed with 5g of calcined TiO 2 The powders were mixed, stirred evenly at room temperature, and then allowed to stand for 6 hours, then transferred to a reactor with a polytetrafluoroethylene substrate and treated at 100°C for 7 hours. After the treatment, take out the reaction kettle, cool it naturally in the air, filter the precipitate in the reaction kettle, wash it with ethanol for 3 times, then wash it with water for 3 times, and then dry it in vacuum at 60°C for 10 hours to obtain a powder; put the dried powder at 500°C Roasted for 4.5h to obtain SO 4 2- Modified TiO 2 load V 2 o 5 solid catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com