Patents

Literature

40results about How to "Selectivity unchanged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing ethylene glycol by ethylene oxide catalytic hydration

InactiveCN1566050AGood hydrothermal stabilityReactiveOrganic compound preparationHydroxy compound preparationThermal energyHydration reaction

The invention relates to a process for preparing ethylene glycol by ethylene oxide catalytic hydration, wherein the solid acid catalyst employs niobium compounds as the main active components, at least one of germanium, tin, lead, antimony, phosphor, sulfur, ferrum and cobalt is used as the auxiliary agent for preparing ethylene alcohol at rather low water ratio conditions, the thermal energy needed for processing reacting excess water can be reduced substantially, the catalyst used possesses not only good activity, selectivity, but also fine steadiness.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst used for hydrating epoxy ethane to prepare ethandiol

ActiveCN100413579CHigh activityHigh selectivityPreparation by hydroxy group additionMetal/metal-oxides/metal-hydroxide catalystsEpoxyHydration reaction

Owner:CHINA PETROLEUM & CHEM CORP +1

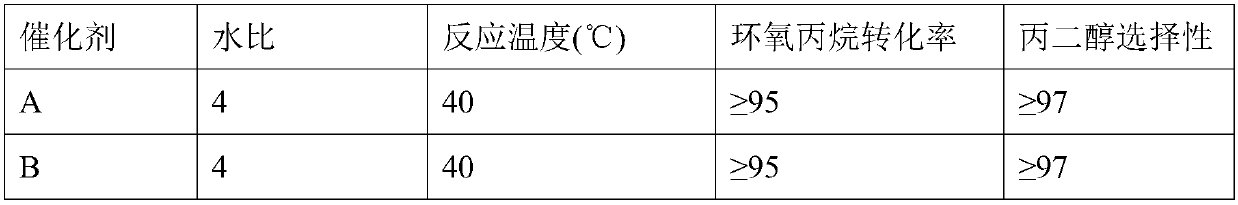

Process for producing alkylene glycol

ActiveCN1721385AReduce swellingImprove thermal stabilityBulk chemical productionPreparation by hydrolysisHydration reactionReaction temperature

The present invention is preparation process of alkylene dyhydric alcohol, and aims at prolonging the service life of catalyst and raising its heat tolerance while maintaining its high conversion rate and selectivity. The technological scheme of the present invention is that the material including alkylene oxide and water in the molar ratio of 1 to 5-15 and macroporous composite resin catalyst are made to contact and react to produce alkylene dyhydric alcohol in the conditions of reaction temperature 60-150 deg.c, reaction pressure 0.5-2 MPa and liquid space velocity 3-6 / hr. The macroporous composite resin catalyst includes monomer, copolymerized monomer, nanometer material, initiator and two assistants and is treated with OH-, Cl-, HSO4-, CHO3- or HCOO- anionic compound. The present invention may be used in industrial production of ethylene oxide catalyzed synthesis of dyhydric alcohol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid acid catalyzer for producing glycol by hydrating ethylene oxide

The invention relates to a solid acid catalyst for preparing glycol by hydration of ethylene oxide for reducing water rate, energy consumption and cost, abating the pollution, and improving catalyst stability. The technology for preparing the catalyst is that: niobium-supported oxide on oxide carrier is served as main active component, VIB metal compound and metal cerium, manganese, thorium or their compound are added as promoter. The catalyst is used for preparing glycol by hydration of ethylene oxide with good activity, selectivity and stability, low energy consumption and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid acid catalyst for preparing ethylene glycol by ethylene oxide hydration

InactiveCN1566049AReactiveHigh activityMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionHydration reactionSolid acid

The invention relates to a solid acid catalyst for preparing ethylene glycol by ethylene oxide hydration, wherein the niobium oxide loaded on oxide carrying agent is used as the main active component, metallic compounds selected from IVA and antimony, phosphor, sulfur, ferrum or cobalt as catalyst promoters, the obtained catalyst can be used for preparing ethylene glycol by ethylene oxide catalytic hydration, which possesses not only good activity, selectivity, but also fine steadiness.

Owner:CHINA PETROLEUM & CHEM CORP +1

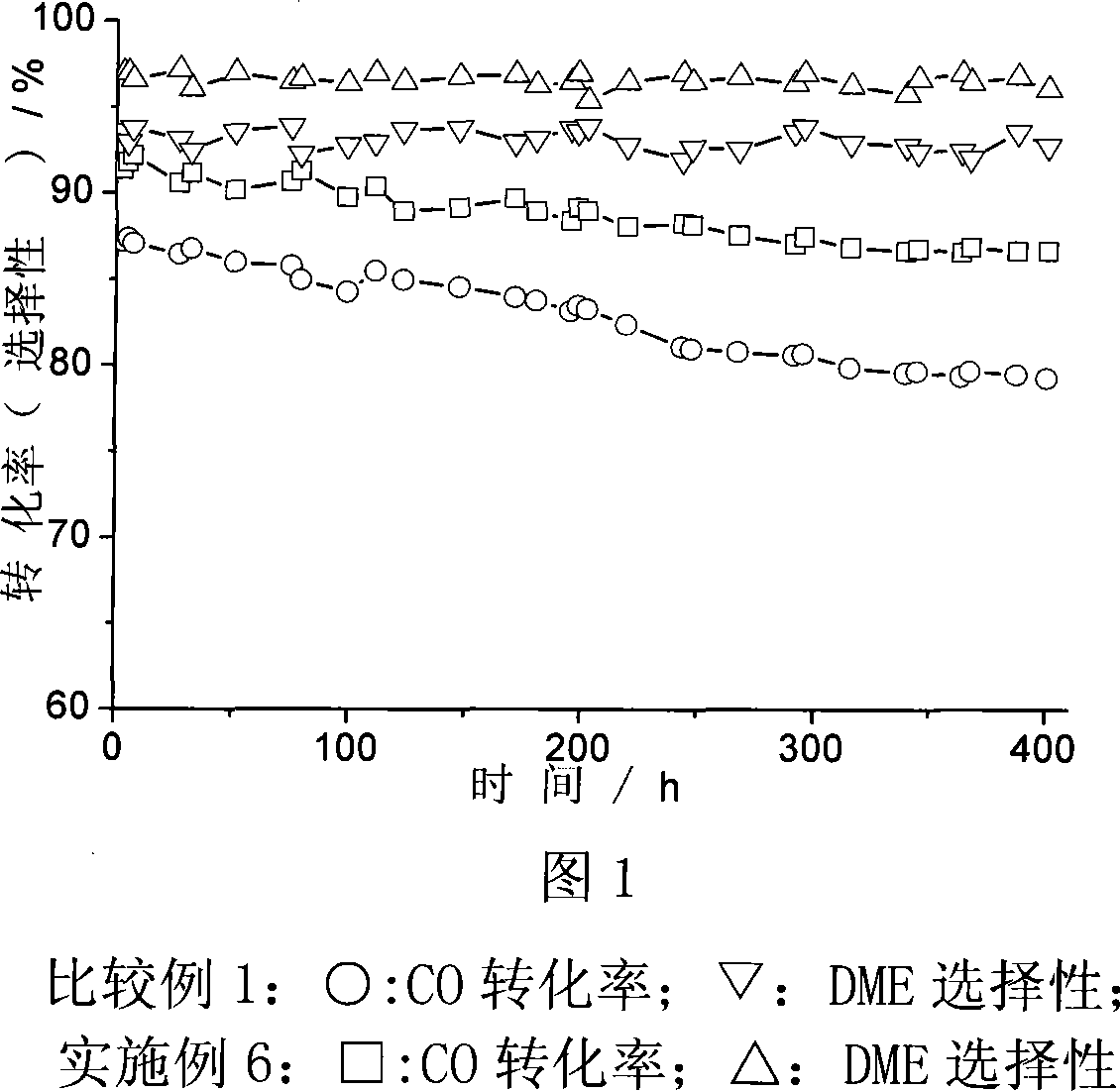

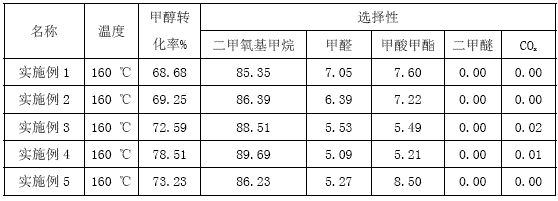

Catalyst of direct synthetic dimethyl ether and preparing method thereof

InactiveCN1583264AHigh catalytic activityImprove stabilityMolecular sieve catalystsCatalyst activation/preparationActive componentOrganic chemistry

A catalyst Cu-Mn-Zn / carrier for directly synthesizing dimethylether is composed of the active components Cu, Mn and Zn and carrier. Its advantages are lower reaction temp and pressure, and high transform rate of Co and output rate of dimethylether.

Owner:ZHEJIANG UNIV

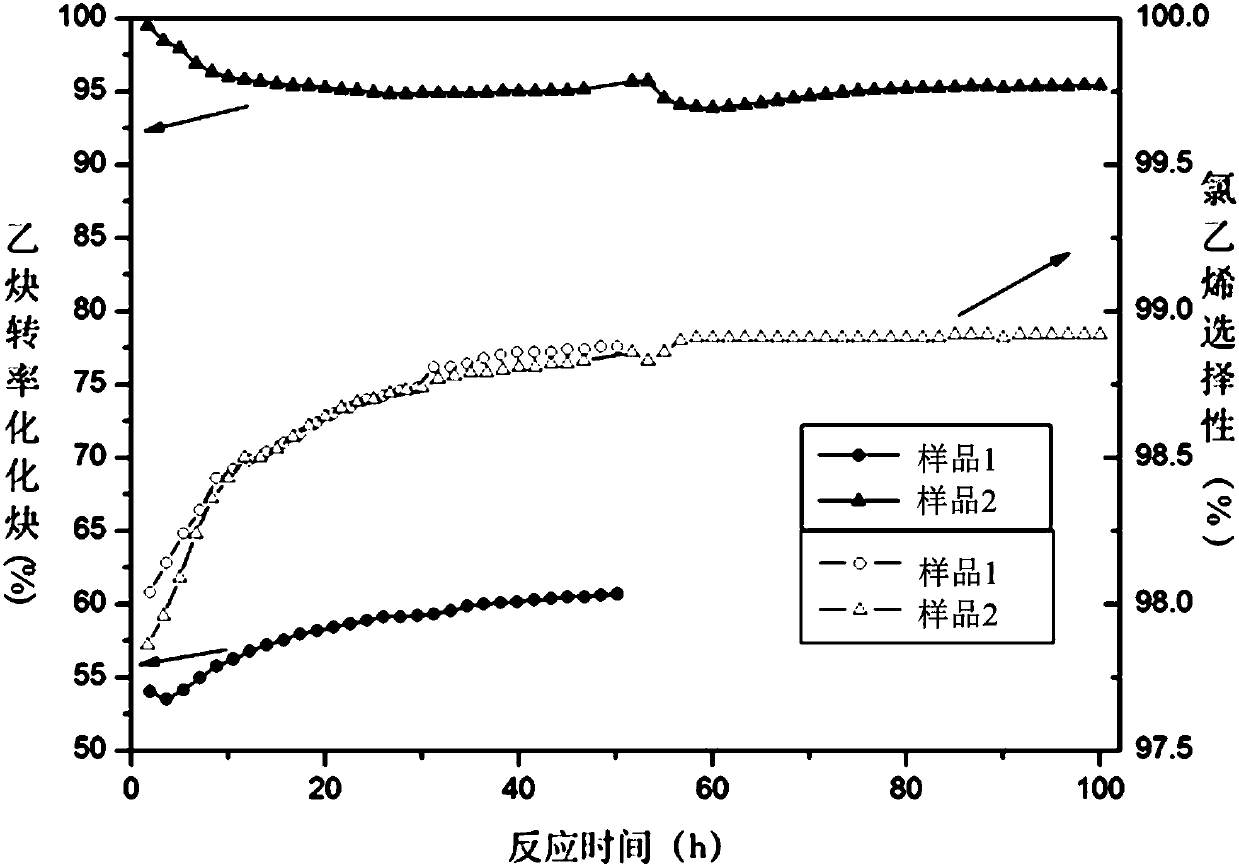

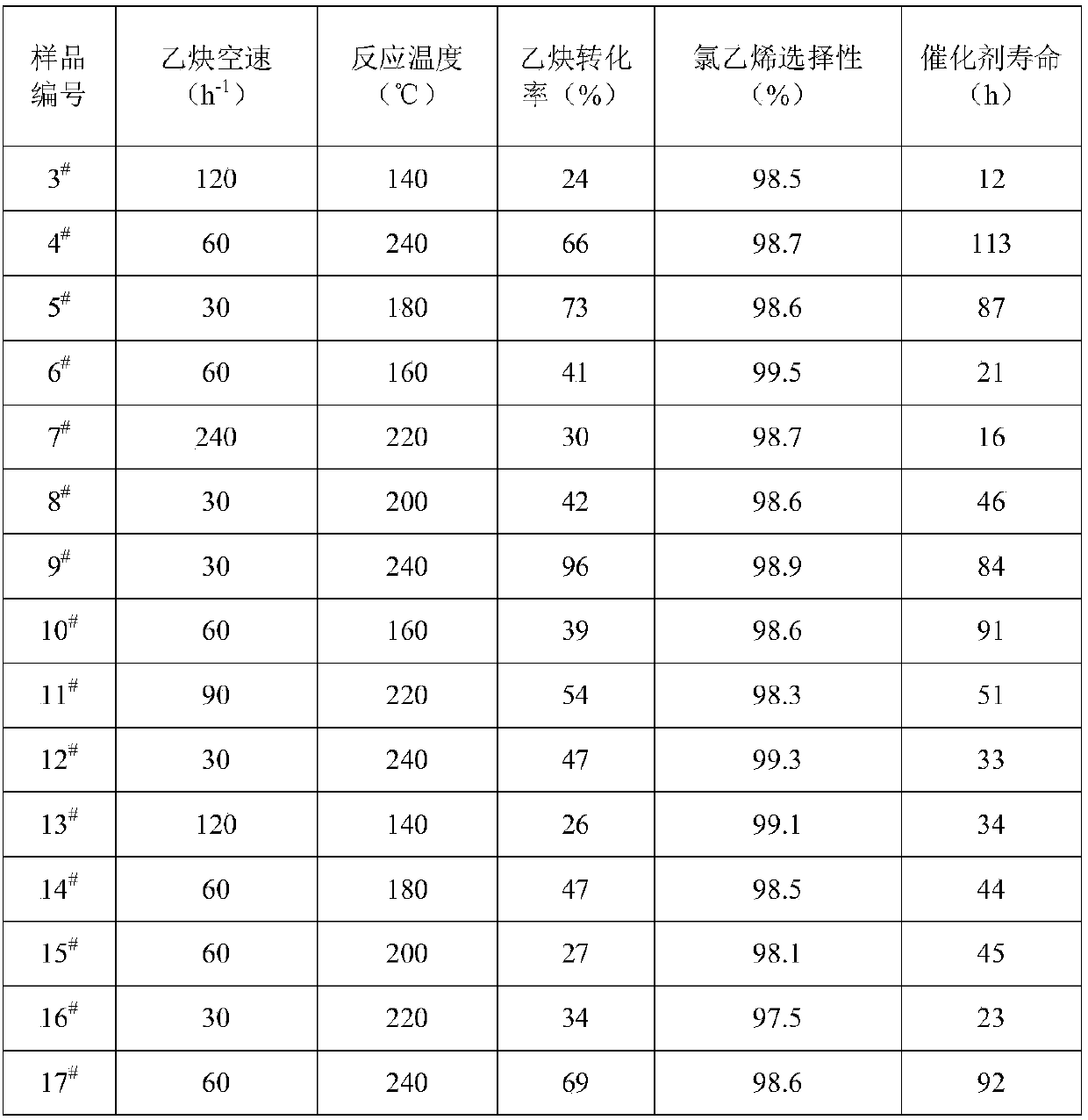

Three-component mercury-free catalyst for hydrochlorination of acetylene and preparation method of catalyst

ActiveCN107983375AHigh reactivityGood choicePhysical/chemical process catalystsPreparation by halogen halide additionCeriumHigh activity

The invention discloses a mercury-free catalyst for hydrochlorination of acetylene and a preparation method of the catalyst. The catalyst contains carrier activated carbon and an active component which is a mixture of three components, wherein the component A is chloroauric acid, the component B is copper chloride, the component C is one of sodium chloride, potassium chloride, rubidium chloride, cesium chloride, magnesium chloride, calcium chloride, cerium chloride and barium chloride, the weight percentage of a gold element in the component A and the carrier is 0.01%-0.1%, the weight percentage of copper chloride in the component B and the carrier is 0.5%-20%, and the weight percentage of the component C and the carrier is 1%-30%. The active component is supported on the carrier through equivalent-volume impregnation, and the novel mercury-free catalyst is obtained with a drying means. The catalyst has very high activity, selectivity and better stability in the reaction for preparingvinyl chloride through hydrochlorination of acetylene.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Solid acid catalyzer for preparing glycol by hydrating ethylene oxide

InactiveCN1565735AReactiveHigh activityOrganic chemistryMolecular sieve catalystsHydration reactionNiobium

The invention relates to a solid acid catalyst for preparing glycol by hydration of ethylene oxide for reducing water rate, energy consumption and cost, abating the pollution, and improving catalyst stability. The technology for preparing the catalyst is that: niobium-supported metal compound on oxide carrier is served as main active component, IVB metal compound and at least one of vanadium or tantalum metal compound are added as promoter. The catalyst is used for preparing glycol by hydration of ethylene oxide with good activity, selectivity and stability, low energy consumption and low cost.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

Non-noble metal acetylene selective hydrogenation catalyst and preparation method and application thereof

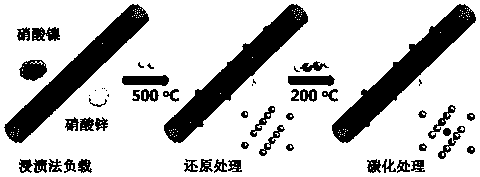

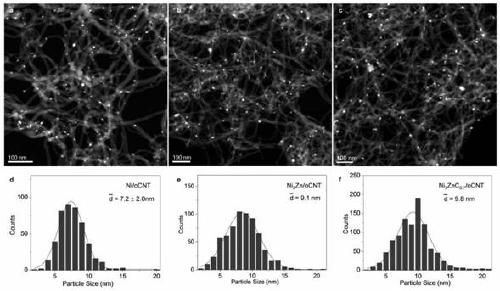

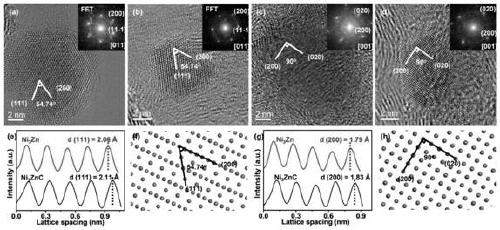

ActiveCN109622000ALow priceReduced activityPhysical/chemical process catalystsHydrocarbon by hydrogenationNickel saltHydrogen atmosphere

The invention discloses a non-noble metal acetylene selective hydrogenation catalyst and a preparation method and application thereof, and belongs to the technical field of loaded nanoparticle catalysts. Nickel salt and zinc salt are loaded on a carbon material through an impregnation method, and the carbon material is firstly treated under a hydrogen atmosphere to obtain a Ni3Zn catalyst, and then is treated under an acetylene atmosphere to obtain a Ni3ZnC0.7 catalyst. A performance test of acetylene selective hydrogenation reaction shows that the catalyst exhibits excellent selectivity (about 82%) in the reaction after the introduction of carbon atoms to form a Ni3ZnC0.7 structure, and a performance test at a high conversion rate for a long time also shows that the structure and activityof the catalyst have good stability.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Integral catalyst for producing dimethyl ether by synthesis gas directly as well as its preparing method

InactiveCN101157049AHigh activityLarge geometric specific surface areaMolecular sieve catalystsEther preparationCordieriteIon

The invention relates to monolithic catalyst directly producing dimethyl ether with synthetic gas, and the preparation method thereof. The monolithic catalyst takes monolithic honeycomb cordierite as the matrix, and takes CuO-ZnO-MxOy / HZSM-5 as active components, MxOy expresses auxiliary agent of the active components, and M can be selected from Al, Zr, B, Ce or La; by quality, the CuO-ZnO-MxOy has 12 to 30 parts, the HZSM-5 has 5 to 16 parts, and the cordierite has 60 to 80 parts. The preparation method of the monolithic catalyst includes that a coating method and a uniform co-precipitation method are utilized. The preparation method has the coating method that dilute nitric acid, surface active agent, deionized water, etc are added into the CuO-ZnO-MxOy obtained in the co-precipitation method or the CuO-ZnO-MxOy-HZSM-5 obtained in the co-precipitation method for the ball milling; after being pulped, the mixture is coated on HZSM-5 / cordierite or the cordierite; and after being dried and roasted, a dimethyl ether monolithic catalyst finished product is obtained. Prepared in the method provided by the invention, the monolithic catalyst directly producing the dimethyl ether with the synthetic gas has good catalytic activity and stability.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

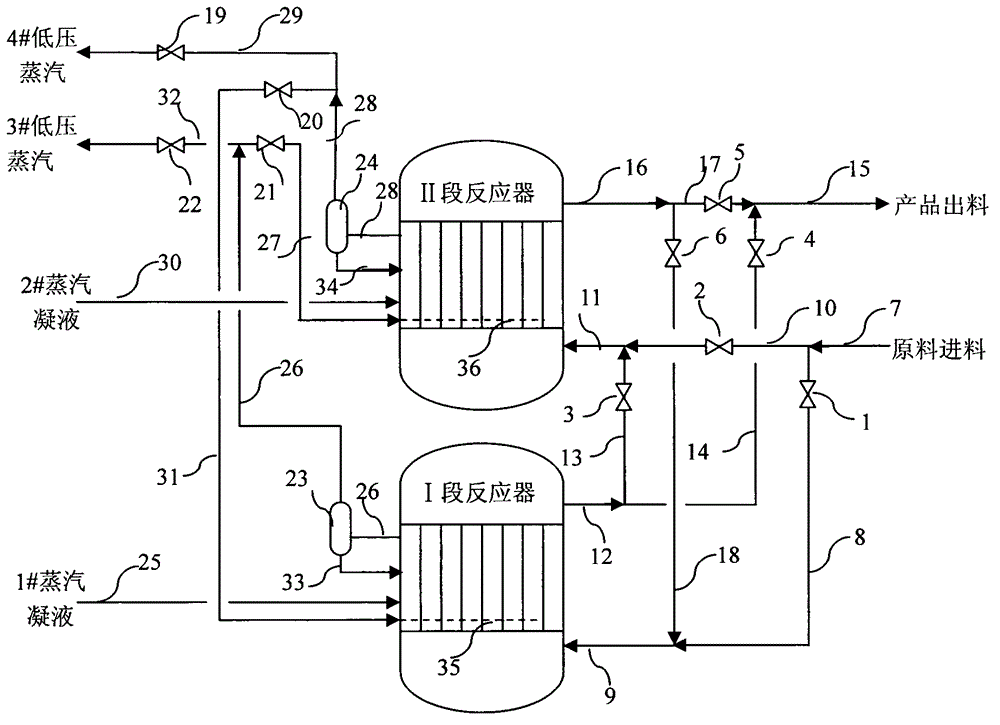

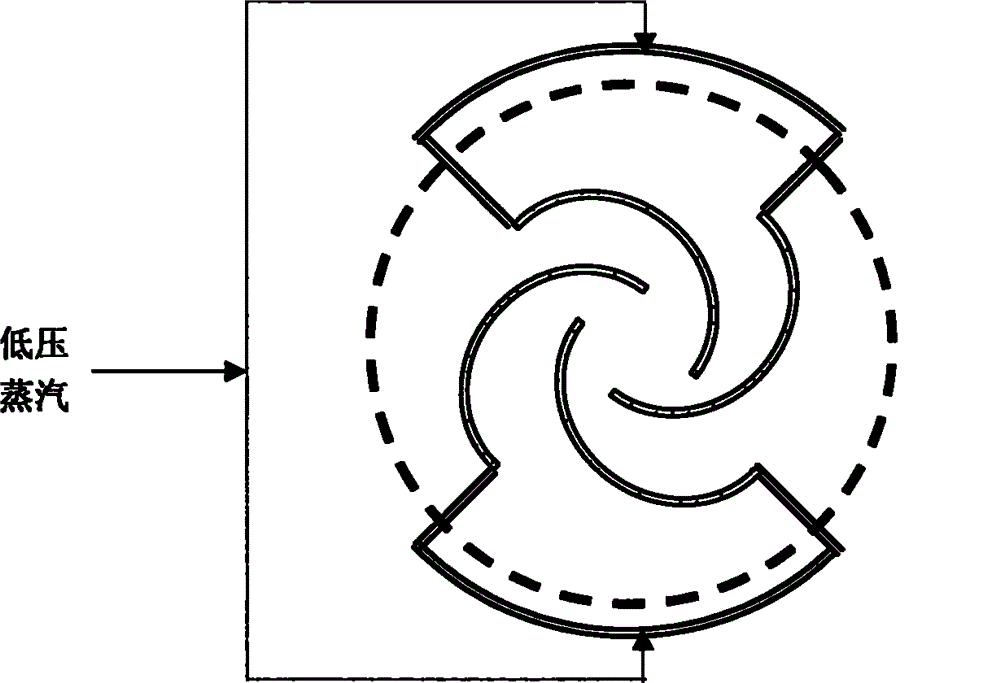

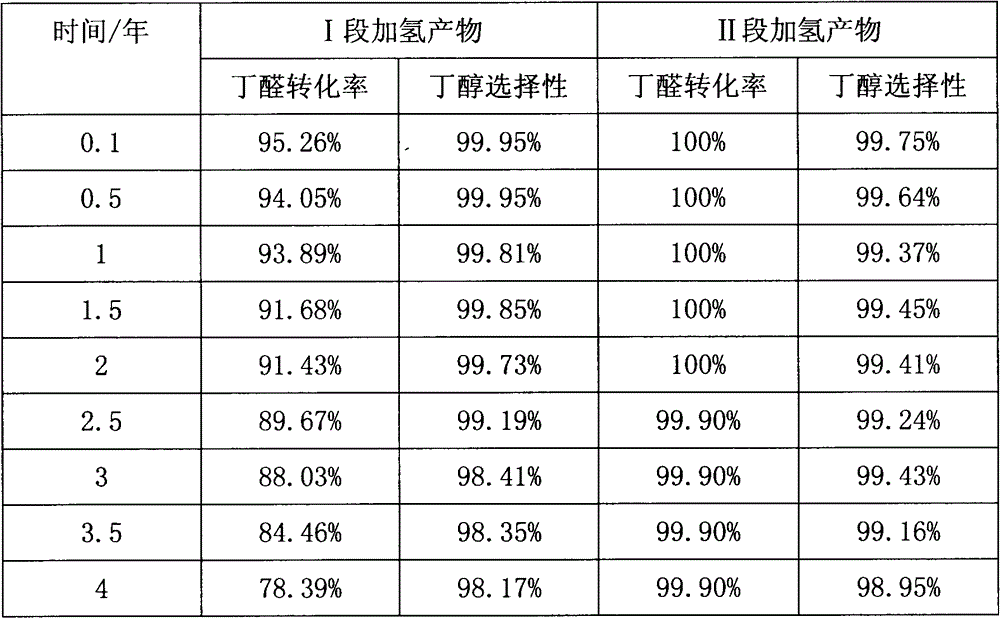

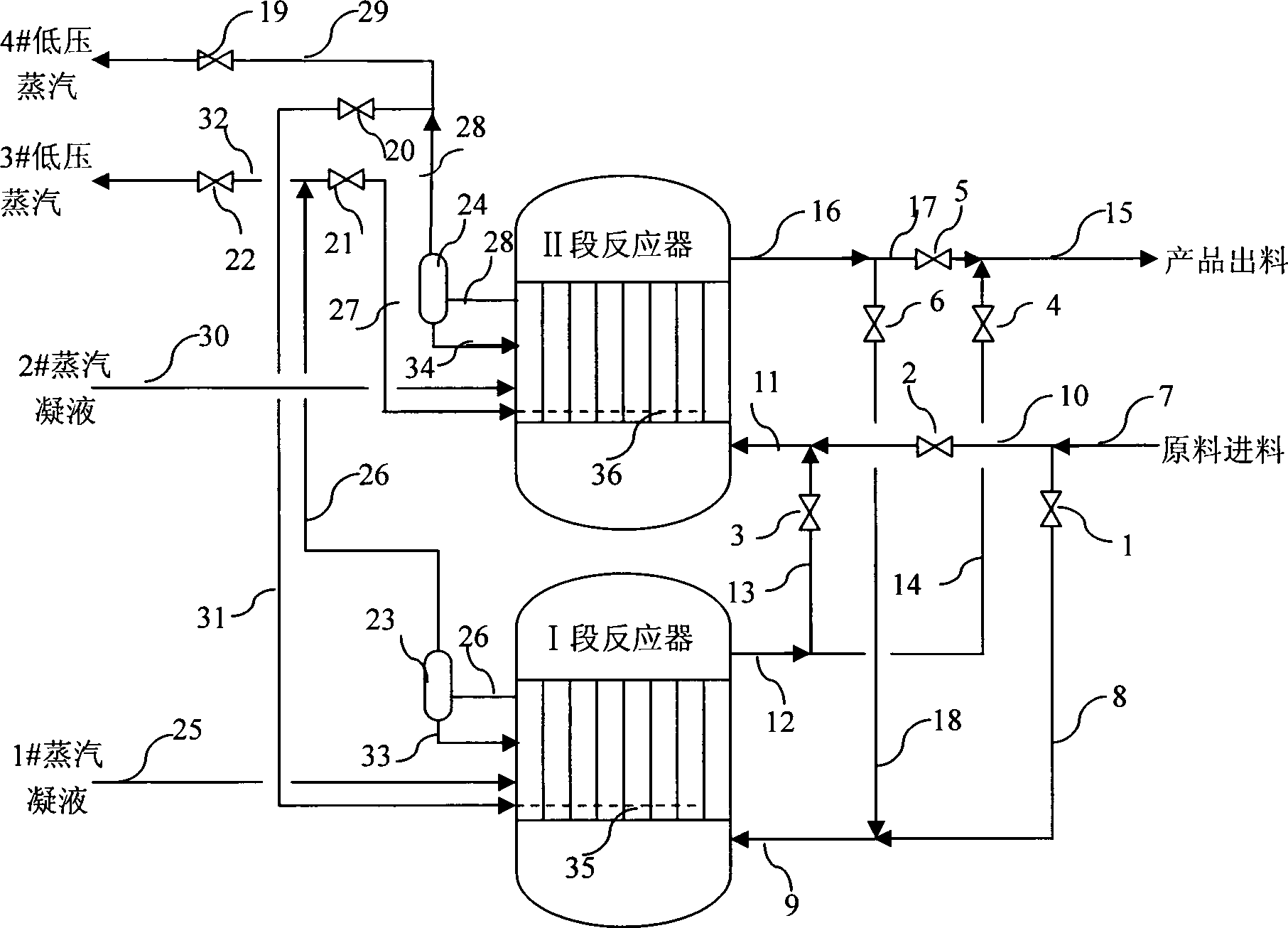

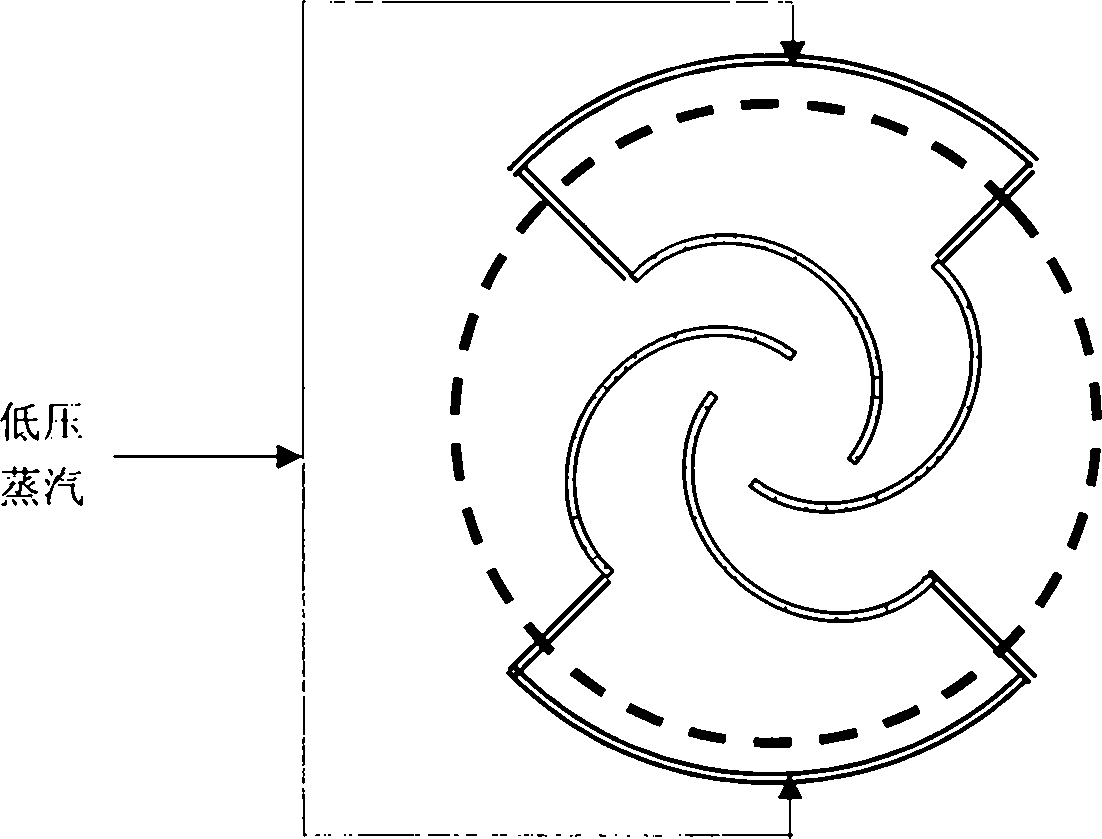

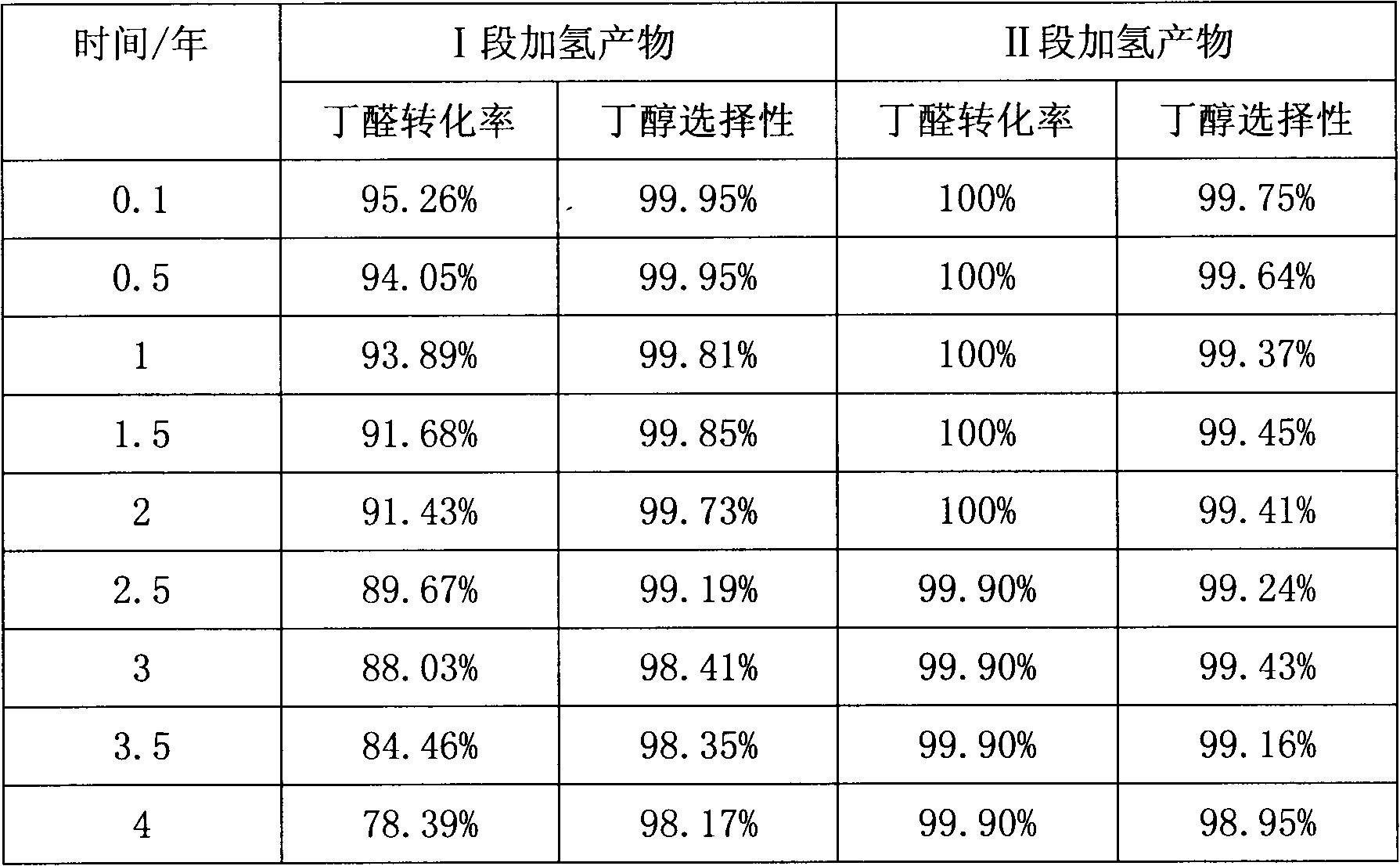

Two-section type switchable tubular reactor and method for preparing alcohol through aldehyde gas phase hydrogenation by using same

ActiveCN103055766ASimple structureReduce the difficulty of processing and manufacturingOrganic compound preparationHydroxy compound preparationAlcoholGas phase

The invention relates to a two-section type switchable tubular reactor and a method for preparing alcohol through aldehyde gas phase hydrogenation by using the same. The reactor comprises an I section reactor, an II section reactor, a valve and pipelines both capable of switching the feeding sequence of raw materials of the two section reactors, and a valve and pipelines both capable of controlling a reaction temperature of the two section reactors. By adopting the two-section switchable tubular reactor for the aldehyde gas phase hydrogenation, the activity of a catalyst in the reactor having the precedent feeding sequence is reduced, but the activity of the catalyst in the reactor having the later feeding sequence is reduced a little after the reaction lasts for a period of time. Through the valve control, the method for preparing alcohol through aldehyde gas phase hydrogenation by using the two-section type switchable tubular reactor has the advantages of realizing the switching of the feeding sequence of the two section reactors and the control of the reaction temperature, increasing the utilization rate of the catalyst, prolonging the service life of the catalyst, prolonging the operating time of a device, saving production cost and the like.

Owner:WANHUA CHEM GRP CO LTD +1

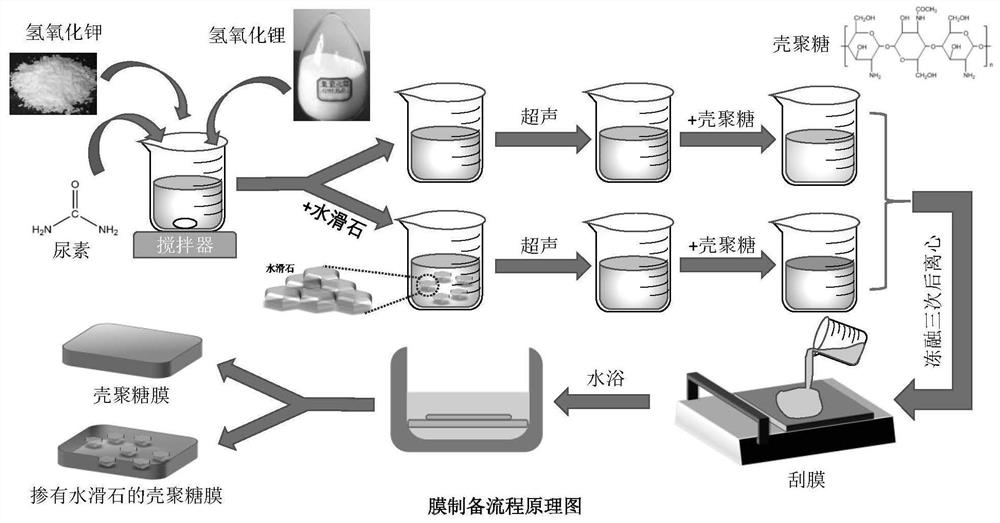

Separation membrane and preparation method thereof, membrane separation equipment and sewage treatment method

PendingCN113304625AEasy to separateIncrease water fluxSemi-permeable membranesMembranesCelluloseNanoparticle

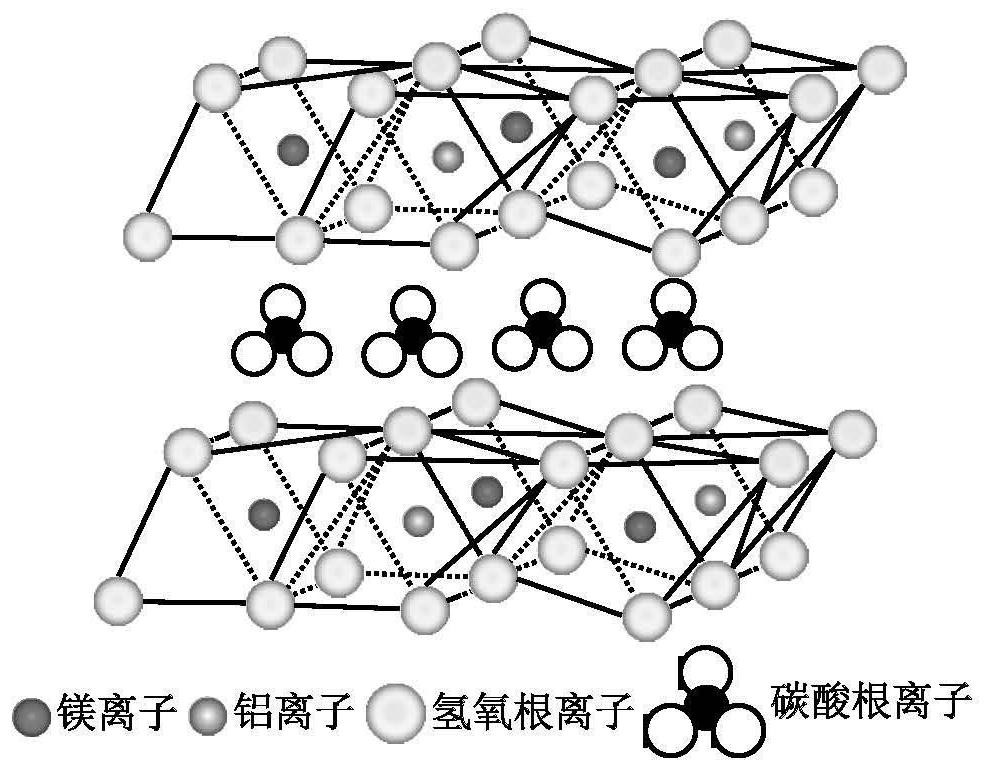

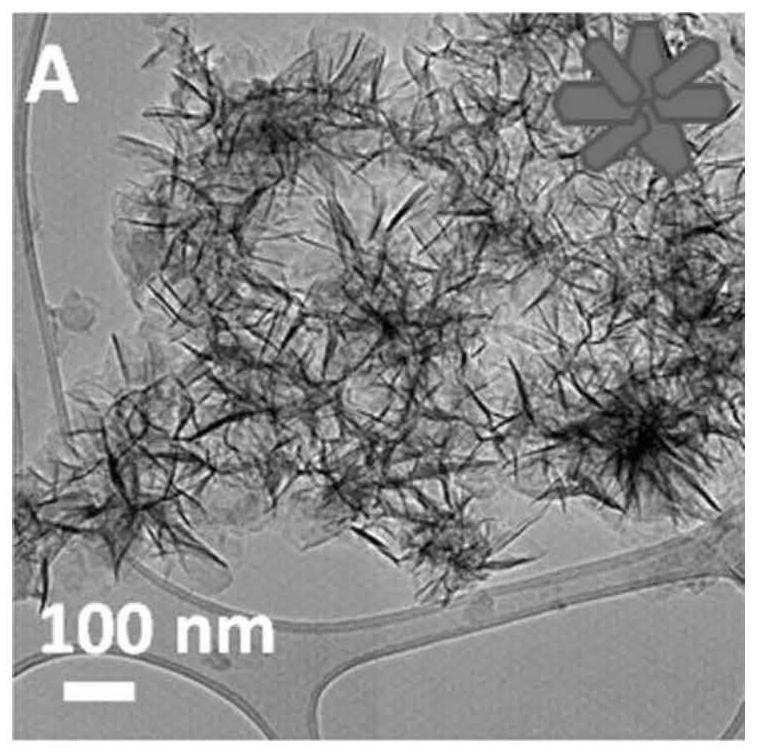

The invention relates to a separation membrane and a preparation method thereof, membrane separation equipment and a sewage treatment method. The separation membrane comprises a natural polymer and layered double-metal hydroxide nanoparticles doped in the natural polymer, the natural polymer is selected from one of chitosan, chitin and cellulose, and the mass of the layered double-metal hydroxide nanoparticles is 0.5-3% of the mass of the natural polymer. Layered double metal hydroxide nanoparticles are doped in a natural polymer, and the hydrophilicity and internal water channels of the layered double metal hydroxide nanoparticles and the influence on the separation membrane forming process and the secondary structure are utilized, so that the separation performance of the separation membrane prepared from the natural polymer as a raw material is improved; therefore, the separation membrane with an excellent separation effect on various pollutants is obtained.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Mercury-free catalyst, preparation method thereof and application to preparation of chloroethylene

ActiveCN109806905AHigh activityHigh selectivityMolecular sieve catalystsPreparation by halogen halide additionMolecular sieveActive component

The invention discloses a mercury-free catalyst, characterized by being prepared from a carrier and an active component, wherein the carrier comprises an FAU type silicon aluminum molecular sieve, andthe FAU type silicon aluminum molecular sieve accounts for 50-100 percent by weight of the carrier; the active component is CuCl2, a weight ratio of CuCl2 to the carrier is (5 to 40) : 100. The catalyst can be used for acetylene hydrochlorination, and is low-cost, excellent in stability and good in activity and selectivity; the environmental pollution problem caused by the use of a highly toxic mercury catalyst is avoided, and the high cost problem of a gold catalyst as a current research hotspot is solved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

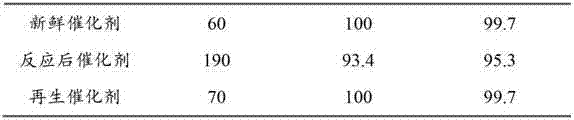

Regeneration method for supported noble metal catalyst

InactiveCN107999057AExtended service lifeLow costSulfonic acids salts preparationCatalyst regeneration/reactivationNitro compoundPtru catalyst

The invention relates to a catalyst, in particular to a regeneration method for a supported noble metal catalyst. According to the regeneration method, a deactivated supported noble metal catalyst isoxidized by a mixed gas of CO2 and O2, and then is reduced by a reducing agent in a tetrahydrofuran solvent after oxidation, so as to obtain the regenerated catalyst. The method has the advantages that the problems that an existing regeneration method for a noble metal catalyst for hydrogenation of a sulfonic-acid-group-containing aromatic nitro compound is poor in stability, industrial amplification is unfeasible, the application range is narrow and the like can be solved, meanwhile, the regeneration method can aim at deactivated noble metal catalysts corresponding to hydrogenation of varioussulfonic-acid-group-containing aromatic nitro compounds, in addition, the regeneration mode is efficient, the regenerated catalyst has relatively high activity and selectivity on the hydrogenation ofthe multiple sulfonic-acid-group-containing aromatic nitro compounds, the service life of the catalyst can be remarkably prolonged, the cost of the catalyst can be lowered, and the method has an industrial application prospect.

Owner:SHENYANG RES INST OF CHEM IND

Recycle method of hydrocyanation catalyst for butadiene-based synthesis of adiponitrile

InactiveCN105017073ARealize self-circulationEliminate the effects ofChemical recyclingPreparation by hydrogen cyanide additionReagentHydrocyanation

The invention discloses a recycle method of a hydrocyanation catalyst for butadiene-based synthesis of adiponitrile. The method comprises that a primary hydrocyanation reaction residual solution separated from products and unreacted reactants is directly used as a catalyst and is recycled in primary hydrocyanation reaction, and / or a part of a secondary hydrocyanation reaction residual solution separated from products and unreacted reactants is replaced by a fresh catalyst and an assistant every time, wherein the replaced amount of the fresh catalyst and the assistant is 5-50wt% the amount of the used fresh catalyst and the assistant, and the treated residual solution is used for secondary hydrocyanation reaction. The recycle method is simple and easy, the primary and secondary hydrocyanation catalysts respectively realize self-circulation, the primary hydrocyanation catalyst can be recycled 10 times or more, the secondary hydrocyanation catalyst can be recycled 30 times or more, and in the process, a reaction transformation rate and product selectivity are basically stable so that a technical cost is reduced and catalyst material ratio change-caused influence on secondary hydrocyanation reaction is eliminated.

Owner:CHONGQING ZHONGPING ZIGUANG SCI & TECH

Preparation method of double effect catalyst for high selective oxidation of methane to prepare dimethoxymethane

InactiveCN105536821AGood dispersionEasy to manufacturePhysical/chemical process catalystsOrganic chemistryOxalateSulfate

The invention belongs to the field of solid catalyst for oxidation reactions for preparing dimethoxymethane, and especially relates to a preparation method of a double effect catalyst for high selective oxidation of methane to prepare dimethoxymethane. The preparation method comprises the following steps: (1) weighing oxalic acid and sulfate, adding distilled water containing ethanol, and stirring to dissolve the solid to obtain a solution A; (2) adding ammonium metavanadate into the solution A obtained in the step (1), and stirring to dissolve the solid ammonium metavanadate to obtain a solution B; (3) mixing burned TiO2 with the solution B obtained in the step (2), evenly stirring the solution at a room temperature, and allowing the system to stand still; (4) transferring the product obtained in the step (3) to a reactor, and heating the product; (5) after heating, taking out the product obtained in the step (4) from the reactor, cooling, filtering the white precipitate in the reactor, filtering, drying in vacuum, and burning the powder obtained in the drying step to obtain the target product. The catalyst has the advantages that the V2O5 is well dispersed, and the catalyst has an oxidation activity and acid center.

Owner:BOHAI UNIV

Solid catalyst for preparing diol by hydrating epoxy compound as well as preparation and application thereof

ActiveCN111097531AEasy to prepareHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDiamineAldehyde formation

The invention discloses a preparation method of a solid catalyst and application of the solid catalyst in preparation of a diol by hydration of an epoxy compound. The preparation method comprises thefollowing steps: 1) mixing and stirring an active metal M precursor, a ligand and a solvent; 2) adding a second metal precursor solution into a product obtained in the step 1), stirring, adding an acid solution and stirring, and 3) adding a diamine solution and an aldehyde solution and refluxing. The preparation method is good in operation convenience and repeatability, the prepared catalyst showsgood catalytic performance in the reaction, is easy to recycle and can be used for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid acid catalyst for preparing glycol by hydrating ethylene oxide

InactiveCN1255216CReactiveHigh activityOrganic chemistryMolecular sieve catalystsHydration reactionHigh energy

The invention relates to a solid acid catalyst for preparing ethylene glycol by hydration of ethylene oxide, which mainly solves the problem of high water ratio, high energy consumption, high production cost, or liquid used in catalytic hydration of ethylene oxide in the past. Acid catalysts corrode equipment, pollute the environment, and solid acid catalysts have poor stability or the defects of stability and activity cannot be taken into account at the same time. A solid acid catalyst for preparing ethylene glycol by hydration of ethylene oxide is provided. The metal compound is used as the main active component, and the technical scheme of at least one auxiliary agent selected from the metal compound of IVB and the metal compound of vanadium or tantalum is optionally added, and the solid acid catalyst prepared is used for the hydration of ethylene oxide to prepare ethylene oxide. The diol reaction not only has good activity and selectivity, is suitable for low water ratio operation, but also has good stability, which can significantly reduce energy consumption and greatly reduce production costs. It can be used in the industrial production of ethylene glycol.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

Catalyst used for hydrating epoxy ethane to prepare ethandiol

ActiveCN1751787AReactiveHigh activityPreparation by hydroxy group additionMetal/metal-oxides/metal-hydroxide catalystsEpoxyHydration reaction

A catalyst for preparing ethanediol by hydrating epoxy ethane is composed of the oxide of carried Nb, at least one element or compound chosen from V, Mo, W, Sn and Pb, and at least one element or compound chosen from La, Pr and Nd. Its advantages are low consumption of water and energy and no corrosion and pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Columbium oxide catalyst for hydrating epoxy ethane to prepare ethandiol

ActiveCN100413578CReactiveHigh activityPreparation by hydroxy group additionMetal/metal-oxides/metal-hydroxide catalystsEpoxyEthylene oxide

A niobium oxide catalyst for preparing ethanediol by hydrating epoxy ethane is a carried oxide of niobium and its raw material is chosen from niobium halide, alkoxyniobium, carboxylic acid derivative of niobium, phenolic niobium, niobium carboxylate and niobium-ammonia complex. Its advantages are low consumption of water and energy, and no corrosion and pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing alkylidene dibasic alcohol

ActiveCN1285554CReduce swellingImprove thermal stabilityBulk chemical productionPreparation by hydrolysisAlkaneHydration reaction

The invention relates to a method for preparing alkylene glycol, and mainly solves the problems of short service life and poor heat resistance of the catalyst used in the prior art under the condition of high conversion rate and selectivity. The present invention uses alkylene oxide and water as raw materials, at a reaction temperature of 60 to 150°C, a reaction pressure of 0.5 to 2.0 MPa, a water / alkylene oxide molar ratio of 5 to 15:1, and a liquid space velocity of 3 to 10 MPa. 6 hours -1 Under conditions, the raw material is contacted with a macroporous composite resin catalyst to generate an alkylene glycol, wherein the macroporous composite resin catalyst includes monomers, comonomers, nanomaterials, initiators, and auxiliary agent one and auxiliary agent two components, and OH for macroporous composite resin - , Cl - 、HSO 4 - 、HCO 3 - or HCOO - The technical scheme of anion compound treatment solves this problem well, and can be used in the industrial production of ethylene oxide catalytic hydration to form dihydric alcohol.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of three-component acetylene hydrochlorination mercury-free catalyst and preparation method thereof

ActiveCN107983375BHigh reactivityGood choicePhysical/chemical process catalystsPreparation by halogen halide additionPtru catalystHigh activity

The invention discloses a mercury-free catalyst which can be used for acetylene hydrochlorination and a preparation method thereof. The catalyst comprises carrier activated carbon and an active component, and the active component is a mixture of three components, wherein component A is chloroauric acid , B component is copper chloride, C component is one of sodium chloride, potassium chloride, rubidium chloride, cesium chloride, magnesium chloride, calcium chloride, cerium chloride, barium chloride, wherein, A The weight percentage of the gold element in the component and the carrier is 0.01% to 0.1%, the weight percentage of the copper chloride in the component B and the carrier is 0.5% to 20%, and the weight percentage of the component C and the carrier is The weight percentage is 1%-30%. The active component is loaded on the carrier by equal volume impregnation, and a new type of mercury-free catalyst is obtained by drying. The catalyst shows high activity, selectivity and good stability in the reaction of acetylene hydrochlorination to prepare vinyl chloride.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Process for preparing ethylene glycol by ethylene oxide catalytic hydration

InactiveCN1218917CHigh activityHigh selectivityOrganic compound preparationHydroxy compound preparationThermal energyHydration reaction

The invention relates to a method for preparing ethylene glycol by catalytic hydration of ethylene oxide, which mainly solves the problem that the non-catalytic hydration water ratio of ethylene oxide in the past is too high, or the liquid acid catalyst used for catalytic hydration corrodes equipment, pollutes the environment, and solidifies Acid catalysts are poor in stability or their stability and activity cannot reach the ideal state at the same time. Provide a method for the catalytic hydration of ethylene oxide to prepare ethylene glycol. The solid acid catalyst used in this method uses niobium compounds as the main active component , using at least one selected from germanium, tin, lead, antimony, phosphorus, sulfur, iron or cobalt as additives, reacting to prepare ethylene glycol under conditions of lower water ratio, which can greatly reduce the need for processing excess water The catalyst used not only has good activity and selectivity, but also has excellent stability, prolongs the operation period of the catalyst, and has the characteristics of low energy consumption and low production cost. It can be used in the industrial production of ethylene glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method and application of zno porous material with multi-core-shell structure

ActiveCN108609647BLarge specific surface areaQuick responseZinc oxides/hydroxidesMaterial resistanceAcetic acidPhysical chemistry

The invention discloses a preparation method and application of a ZnO porous material adopting a multi-core-shell structure. The preparation method comprises the following steps: 1, dissolving zinc acetate dehydrate in a methanol solution, magnetically stirring for 10min, performing ultrasonic treatment for 10min, and then continuing to magnetically stir for 10min to obtain a solution A; 2, dissolving salicylic acid in a methanol solution, and magnetically stirring for 20min to obtain a solution B; 3, mixing the solution A and the solution B, magnetically stirring for 10min, then transferringa mixed solution to a reaction kettle, and placing the mixed solution together with the reaction kettle in a drying oven, reacting for 24 hours at 160 DEG, washing a reaction product for three times by using ethanol and water respectively, and then drying at 60 DEG C for 12 hours in the drying oven to obtain pale yellow powder; 4, calcinating the pale yellow powder for 2h to obtain the ZnO porousmaterial adopting the multi-core-shell structure. The preparation method is simple, and the obtained ZnO porous material adopting the multi-core-shell structure is wide in application field.

Owner:NANJING TECH UNIV +1

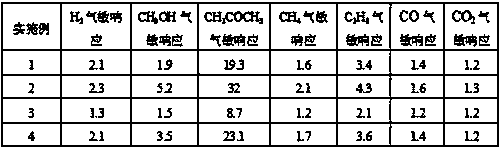

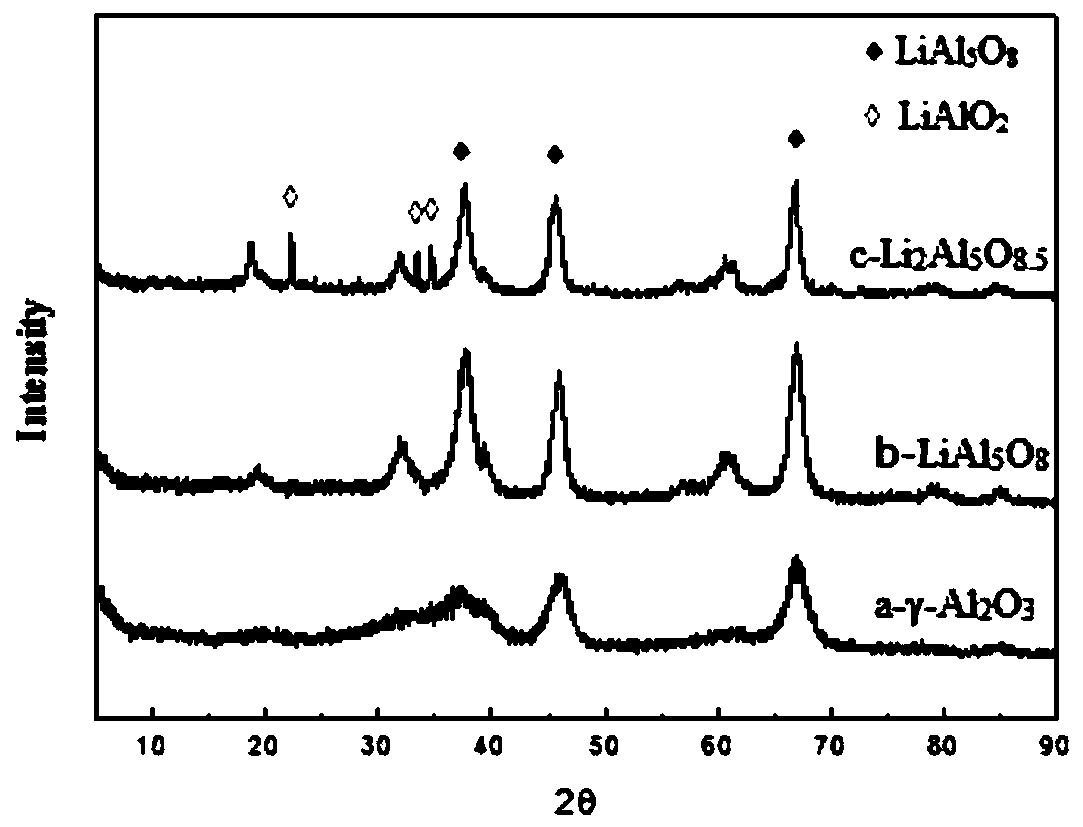

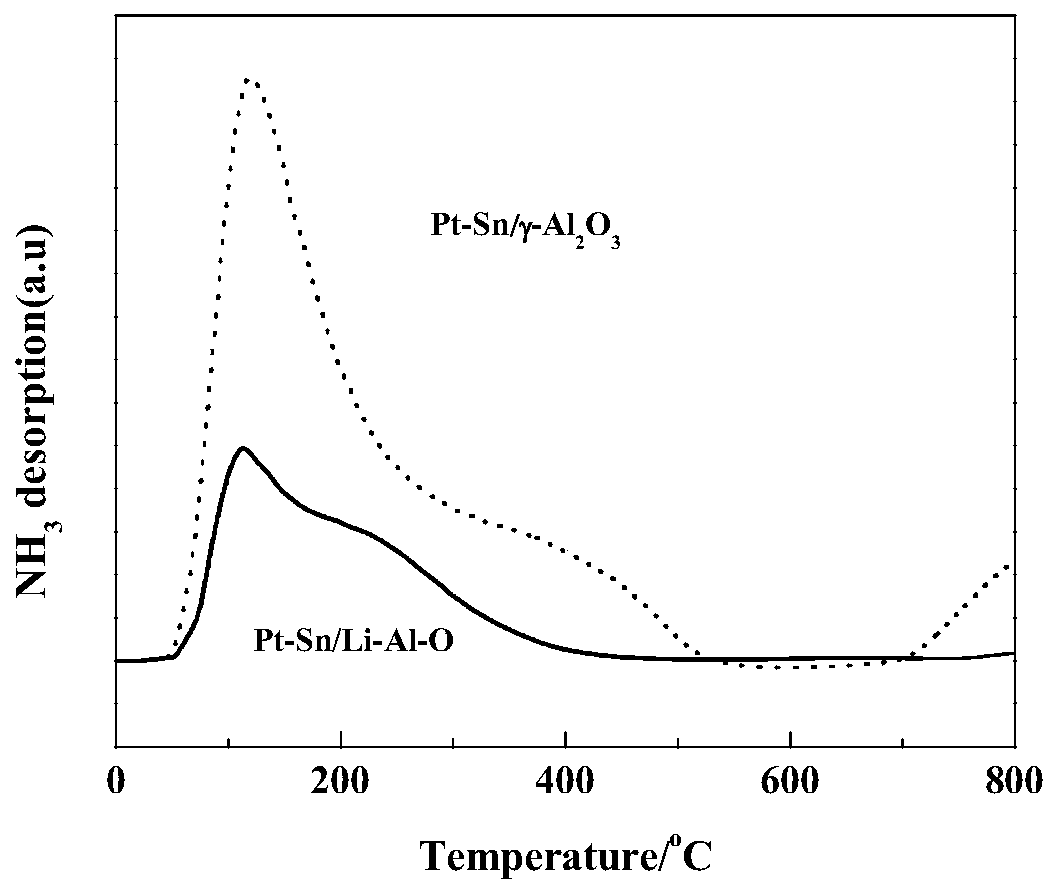

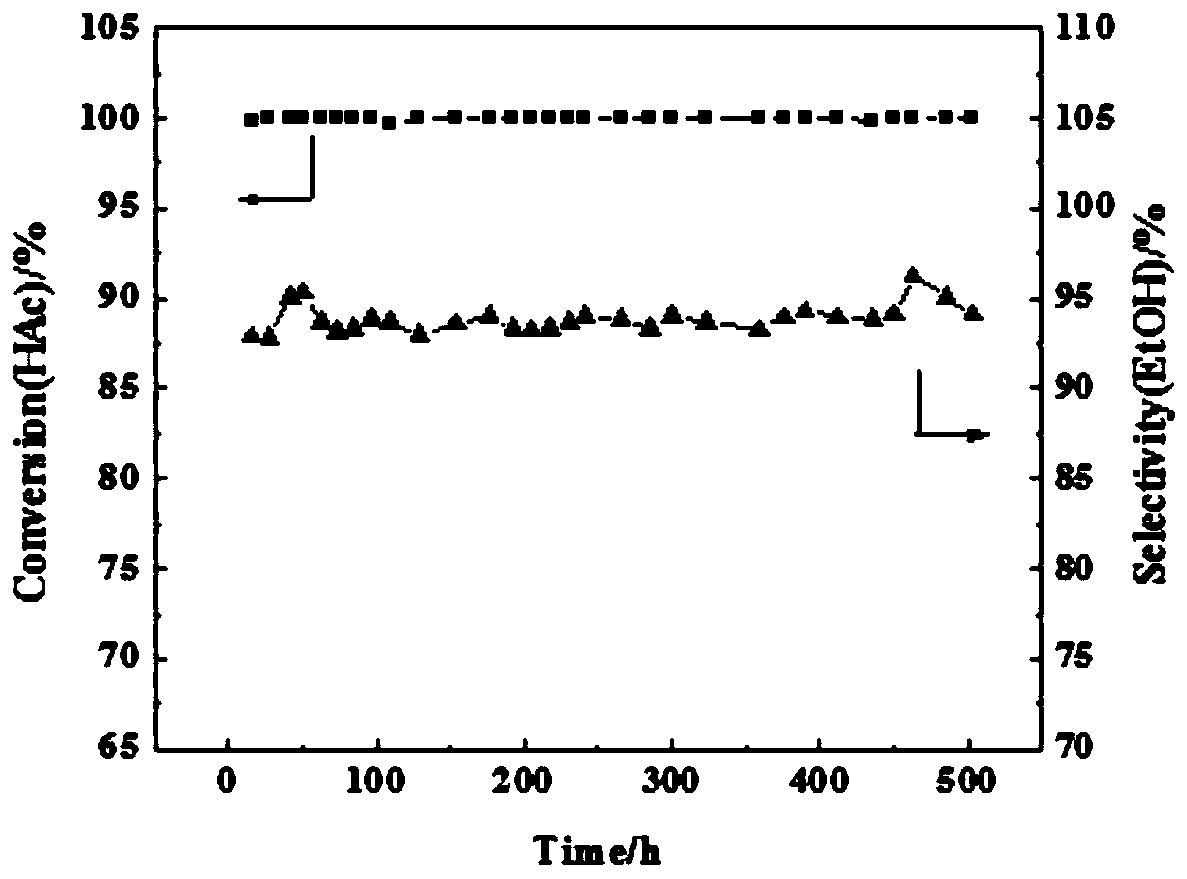

A kind of preparation method of acetic acid hydrogenation ethanol pt-sn/li-al-o catalyst

ActiveCN107115863BReduce surface acidityGood dispersionCatalyst carriersOrganic compound preparationAcetic acidLithium

The invention provides a preparation method of an ethanol Pt-Sn / Li-Al-O catalyst through acetic acid hydrogenation and belongs to the technical field of catalyst preparation. The method comprises the steps of (1) immersing Al2O3 into a soluble metal salt solution containing lithium, drying and roasting to obtain a Li-Al-O carrier; and (2) immersing the obtained Li-Al-O carrier into a soluble metal salt solution containing active components Sn and Pt and then drying and roasting to obtain a Pt-Sn / Li-AlO catalyst. The Li-Al-O of a lithium aluminum spinel structure is adopted as the carrier, the surface property of the carrier is stable and the dispersibility of the active components can be improved, thereby improving the activity and the stability of a finished product catalyst. The prepared catalyst has relatively low surface acid property and the selectivity of ethanol can be effectively improved. The method is applied to preparation of the ethanol through acetic acid hydrogenation, so that the acetic acid conversion rate can reach 100% and the ethanol selectivity can reach over 95%. The catalyst prepared through the preparation method has good stability, and the catalyst activity and the ethanol selectivity are basically kept invariable after reaction for 500h.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Process for producing alkylidene dibasic alcohol

ActiveCN1285553CReduce swellingImprove thermal stabilityBulk chemical productionPreparation by hydrolysisAlkaneHydration reaction

The invention relates to a method for preparing alkylene dihydric alcohols, and mainly solves the problems of short service life and poor heat resistance of catalysts used in the prior art under conditions of high conversion rate and selectivity. The present invention uses alkylene oxide and water as raw materials, at a reaction temperature of 60 to 150°C, a reaction pressure of 0.5 to 2.0 MPa, a water / alkylene oxide molar ratio of 5 to 15:1, and a liquid space velocity of 3 to 10 MPa. 6 hours -1 Under the conditions, the raw material is contacted with the composite resin catalyst to generate alkylene glycol, wherein the composite resin catalyst includes monomers, comonomers, nanomaterials, initiators and auxiliary components, and the composite resin uses OH - , Cl - 、HSO 4 - 、HCO 3 - or HCOO - The technical scheme of anion compound treatment solves this problem well, and can be used in the industrial production of ethylene oxide catalytic hydration to form dihydric alcohol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Two-section type switchable tubular reactor and method for preparing alcohol through aldehyde gas phase hydrogenation by using same

ActiveCN103055766BSimple structureReduce the difficulty of processing and manufacturingOrganic compound preparationHydroxy compound preparationAlcoholGas phase

The invention relates to a two-section type switchable tubular reactor and a method for preparing alcohol through aldehyde gas phase hydrogenation by using the same. The reactor comprises an I section reactor, an II section reactor, a valve and pipelines both capable of switching the feeding sequence of raw materials of the two section reactors, and a valve and pipelines both capable of controlling a reaction temperature of the two section reactors. By adopting the two-section switchable tubular reactor for the aldehyde gas phase hydrogenation, the activity of a catalyst in the reactor having the precedent feeding sequence is reduced, but the activity of the catalyst in the reactor having the later feeding sequence is reduced a little after the reaction lasts for a period of time. Through the valve control, the method for preparing alcohol through aldehyde gas phase hydrogenation by using the two-section type switchable tubular reactor has the advantages of realizing the switching of the feeding sequence of the two section reactors and the control of the reaction temperature, increasing the utilization rate of the catalyst, prolonging the service life of the catalyst, prolonging the operating time of a device, saving production cost and the like.

Owner:WANHUA CHEM GRP CO LTD +1

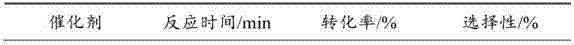

Regeneration method of Pd/C catalyst and application of regenerated Pd/C catalyst

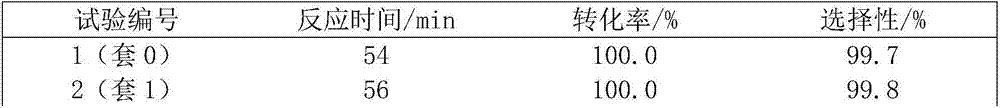

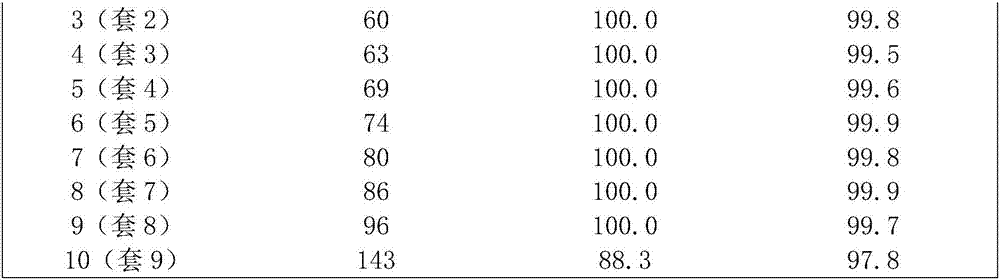

InactiveCN103191759BRestore activitySelectivity unchangedChemical recyclingSulfonic acid preparationAir atmosphereOrganic chemistry

The invention discloses a regeneration method of a Pd / C catalyst and an application of the regenerated Pd / C catalyst. The Pd / C catalyst is inactivated due to poisoning by sulfur-containing substances during the process of catalyzing the hydrogenation synthesis of m-aminobenzenesulfonic acid from m-nitrobenzenesulfonic acid; and the regeneration method comprises the steps of drying and oxidizing the inactivated Pd / C catalyst in an air atmosphere at the temperature of 50-140 DEG C to obtain the regenerated Pd / C catalyst. The Pd / C catalyst obtained by regeneration according to the regeneration method disclosed by the invention can be applied to the reaction of catalyzing the hydrogenation synthesis of the m-aminobenzenesulfonic acid from the m-nitrobenzenesulfonic acid. The method disclosed by the invention is environment-friendly and pollution-free, can effectively restore the activity of the Pd / C catalyst which is inactivated due to the positioning of the sulfur-containing substances during the process of catalyzing the hydrogenation synthesis of the m-aminobenzenesulfonic acid from the m-nitrobenzenesulfonic acid, can ensure that the catalyst can be mechanically used for more than 80 times in a circulating manner, and can keep the activity of the catalyst and the selectivity of the target product unchanged.

Owner:ZHEJIANG UNIV OF TECH +1

A kind of method for preparing vinyl chloride by low-temperature acetylene hydrochlorination

ActiveCN106866349BGood choiceHigh reactivityPhysical/chemical process catalystsPreparation by halogen halide additionPtru catalystFixed bed

The present application relates to a method for preparing vinyl chloride by hydrochlorination of acetylene at low temperature. The method is to generate vinyl chloride by passing acetylene and hydrogen chloride feed gas through a fixed bed reactor under the condition of lower than 100°C. The used catalyst includes an activated carbon carrier and an active component, the active component is a mixture of chloroauric acid and soluble copper salt, wherein the weight percentage of gold element and carrier is 0.01 to 0.1%, and the weight percentage of copper element and carrier is 20% ~100%. The reaction temperature of the method of the invention is low; the carbon deposition of the catalyst during the operation process can be effectively controlled, thereby helping to prolong the life of the catalyst, and at the same time, the energy consumption of the reaction process and the generation amount of by-products can be reduced. The method of the invention is suitable for the process of preparing vinyl chloride monomer by the calcium carbide acetylene method, and has good industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Solid acid catalyst for hydration of epoxy ethane to produce ethandiol

ActiveCN1277607CHigh activityHigh selectivityMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsHydration reactionEpoxy

A solid acid catalyst for preparing ethanediol by hydrating epoxy ethane is composed of oxide carrier, active component (niobium compound), and the assistant chosen from the compound of metal in IVA or VIB and the metal compound containing Ce or Th. Its advantages are high activity, selectivity and stability, and low consumption of water and energy.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com