Regeneration method of Pd/C catalyst and application of regenerated Pd/C catalyst

A catalyst and reaction technology, applied in the field of regeneration of Pd/C catalyst, can solve problems such as easy combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

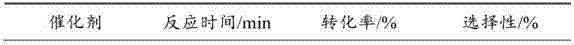

Embodiment 1

[0026] In the reaction of catalyzing the hydrogenation of m-nitrobenzenesulfonic acid to synthesize m-aminobenzenesulfonic acid, add 200g of industrial-grade m-nitrobenzenesulfonic acid solution with a mass concentration of 60wt% in a 500mL autoclave, and use a mass concentration of 30wt % NaOH solution to adjust the pH to 7, and add 1g of 5wt% Pd / C catalyst. The hydrogenation reaction temperature is 75°C and the reaction pressure is 1MPa. Among them, the Pd / C catalyst is selected from fresh catalyst, catalyst recovered by filtration after reaction, and catalyst recovered by filtration after reaction and then regenerated by air oxidation. The catalyst regeneration method is as follows: the deactivated Pd / C catalyst is dried and oxidized under the air atmosphere, the drying temperature is 120° C., and the drying time is 4 hours.

[0027]

[0028]

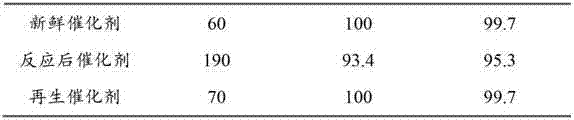

Embodiment 2

[0030] In the reaction of catalyzing the hydrogenation of m-nitrobenzenesulfonic acid to synthesize m-aminobenzenesulfonic acid, add 200g of industrial-grade m-nitrobenzenesulfonic acid solution with a mass concentration of 50wt% in a 500mL autoclave, and use a mass concentration of 20wt % KOH solution to adjust the pH to 6.5, add 1g3wt%Pd / C catalyst. The reaction temperature is 95° C., and the reaction pressure is 0.8 MPa. Among them, the Pd / C catalyst is selected from fresh catalyst, catalyst recovered by filtration after reaction, and catalyst recovered by filtration after reaction and then regenerated by air oxidation. The catalyst regeneration method is as follows: the deactivated Pd / C catalyst is dried and oxidized under air atmosphere, the drying temperature is 70° C., and the drying time is 10 h.

[0031]

Embodiment 3

[0033] In the reaction of catalyzing the hydrogenation of m-nitrobenzenesulfonic acid to synthesize m-aminobenzenesulfonic acid, add 200g of industrial-grade m-nitrobenzenesulfonic acid solution with a mass concentration of 55wt% in a 500mL autoclave, and use a mass concentration of 25wt % NaOH solution to adjust the pH to 7, and add 1g of 5wt% Pd / C catalyst. The reaction temperature is 85° C., and the reaction pressure is 1 MPa. Among them, the Pd / C catalyst is recovered by filtration after the reaction, and then regenerated by air oxidation to continue to be used in the next reaction. The catalyst regeneration method is as follows: the deactivated Pd / C catalyst is dried and oxidized under the air atmosphere, the drying temperature is 110° C., and the drying time is 8 hours. A total of 80 applied experiments were carried out, wherein a small amount of fresh catalyst was added after every several reactions.

[0034]

[0035]

[0036]

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com